The above-said operations must

be carried out only by qualifi e d

technicians.

9

19

19

SERVICING

In all cases, before performing any internal

checks make sure that:

1. the power supply to the device is

disconnected

2. there is no pressurised gas inside the device

• DN 15 ÷ DN 25: (see fi g . 1 a n d 2 ) u n s c r e w

the coil fi x i n g s c r e w s ( 12) (or the slow

opening kit (17)) and remove the coil

(11). Unscrew the cover fi x i n g s c r e w s

(9) and disassemble it from body valve

(4). Check the obturator (5), clean or if is

necessary sobstitute the rubber made seal

component. Clean the fi l t e r ( 8) blowing it

without taking it off the body valve (4).

Then assemble doing backward the same

operation of dismantling.

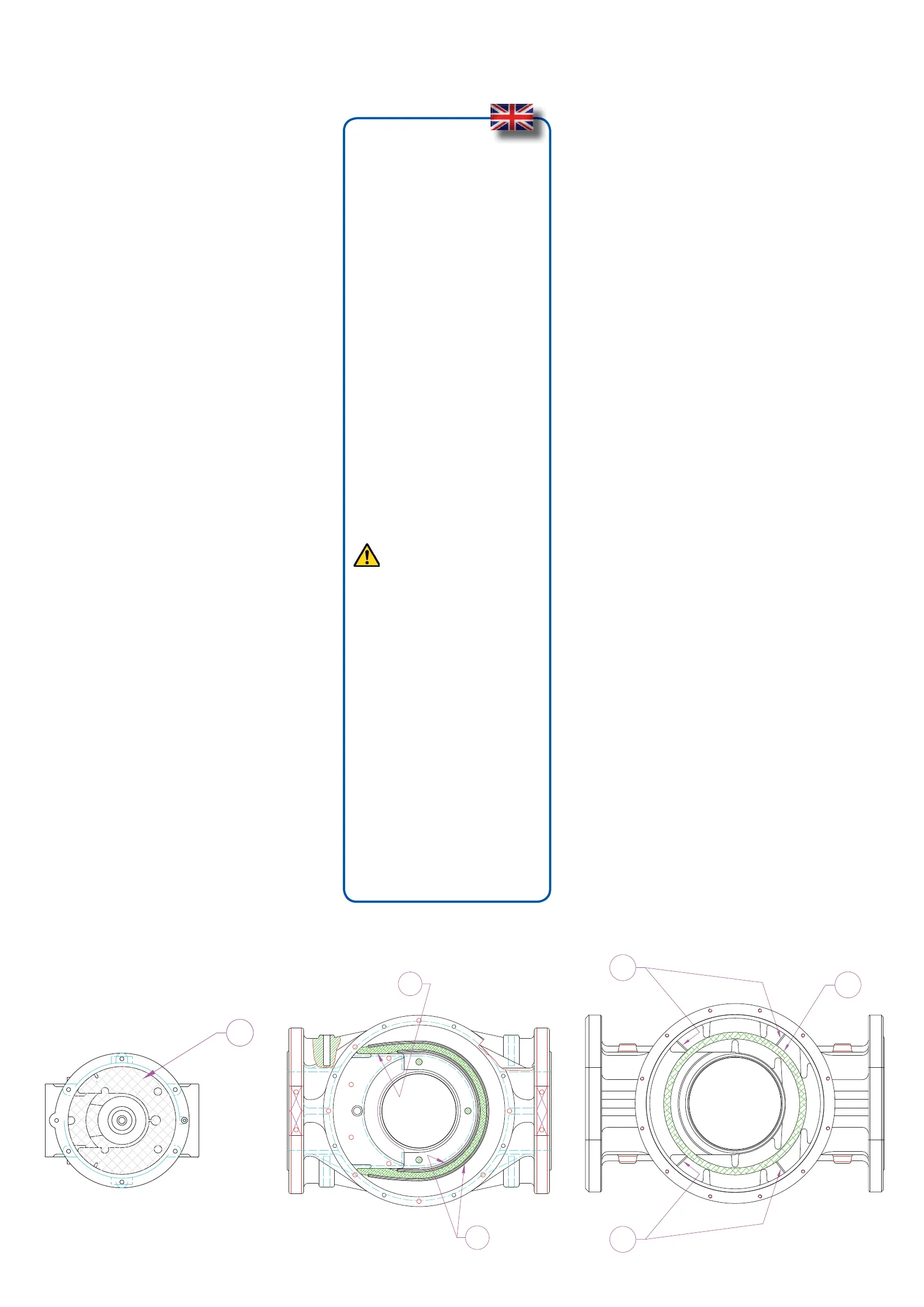

• DN 32 ÷ DN 150: (see fi g . 3 , 4 , 5 , 6 ) u n s c r e w

the nut (12) (or the slow opening kit (17))

and remove the coil (11). Unscrew the

fi x i n g s c r e w s ( 9) and, with care, take the

cover (10) off the body (4) of the valve,

then control the obturator (5) and if it is

necessary change the rubber made seal

component (6). Then clean or blow the fi l t e r

(8) or change it if necessary; then assemble

doing backward the same operation.

VIEW: BODY OF THE VALVE WITHOUT

COVER

TO INSERT THE NET

DN 32 ÷ DN 50:

Position it as in the fi g u r e t a k i n g c a r e t o r e s p e c t

the guides in the internal circumference of

the body valve and fi x i t b y t h e t h r e e s p e c i a l

screws (M3x10).

TO INSERT THE FILTERING ORGAN:

DN 65 ÷ DN 100:

Position it as in the fi g u r e t a k i n g c a r e t o p u t

it inside the guides (18).

DN 125 - DN 150:

Put it as in fi g u r e , s o t h a t t h e s p e c i a l fi n s ( 19)

are leant against the body. So reassemble

the cover paying attention that the O-Ring

is into the right hole.

18

8

8

fi g . 5

Loading...

Loading...