D-5

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

Clutch

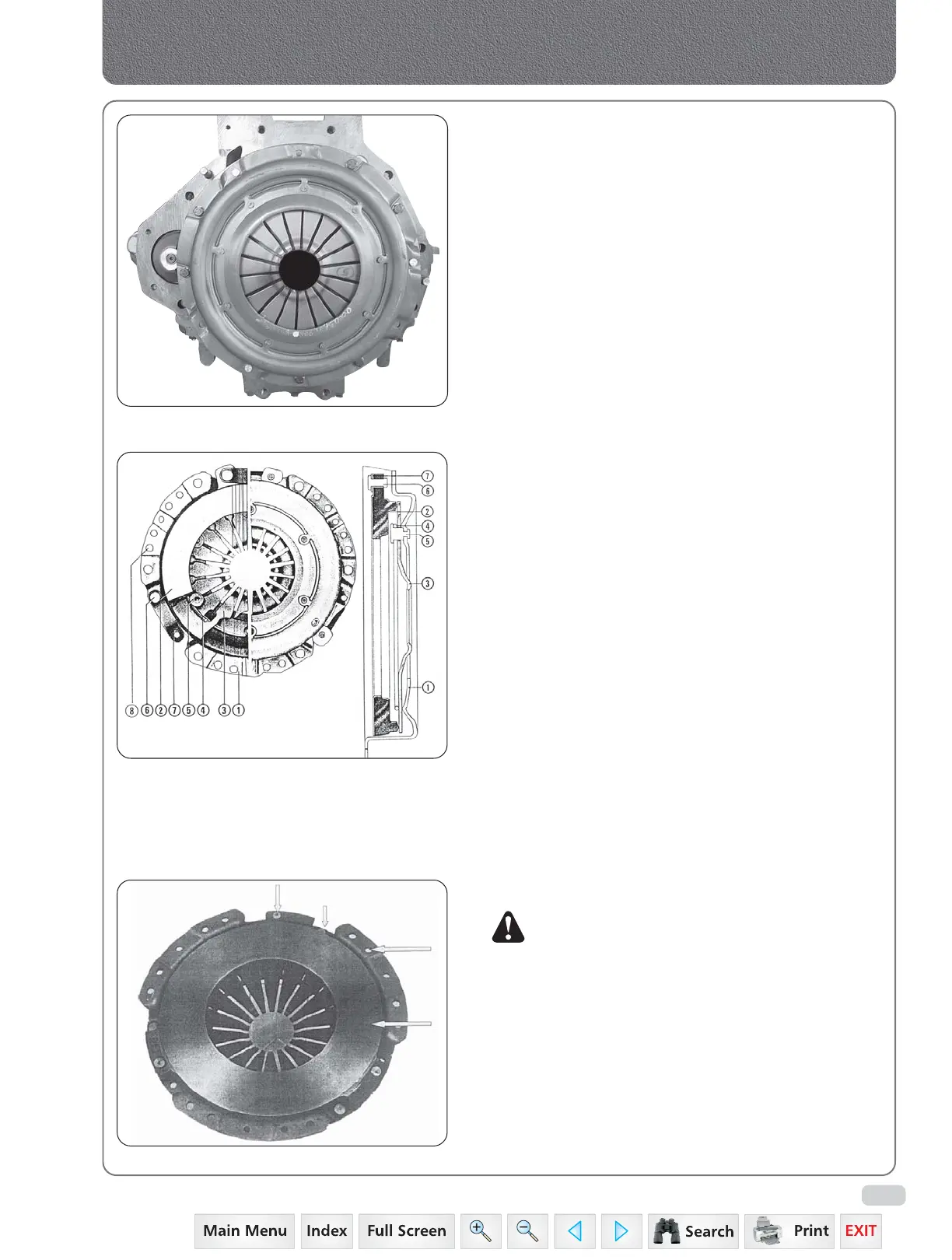

Fig. 3

Fig. 1

3. SINGLE PLATE DIAPHRAGM CLUTCH

The single plate clutch is a foot operated dry plate type.

It consists of a driven plate assembly, cover assembly

and a release bearing assembly. The driven plate

assembly is clamped between the flywheel rear face

and the cover assembly which is bolted to the flywheel.

The cover assembly is composed of compress steel cover,

a diaphragm, a pressure plate, a belleville washer, return

spring and antidrop rivets and clutch assembly mounting

bolts with washer. The cover assembly is bolted to the

flywheel. The diaphragm is made of spring steel, a flat

spring or belleville washer fingers are cut out in the

center. When assembled to the cover the diaphragm

is pressed to create tension in spring and load the

pressure plate.

A tangential drivestrap (7-2) maintain the diaphragm

against the fulcrum in the cover (C P type cover).

The pressure plate is held against the diaphragm by

return spring. The return springs are fasten by rivets

(6-2) to the cover and pressure plate. Antidrop rivets

are provided to prevent excessive movement of pressure

plate.

4. REMOVAL

1. To remove the clutch engine must be separated

from the clutch housing. Apply parking hand brake

and wedge to rear tire.

2. For spliting the tractor between clutch housing

and engine refer the procedure as detailed in

“Spliting The Tractor”.

3. Punch the mark matching clutch cover and

flywheel position to ensure that the clutch is

installed in its original position.

4. Remove the cap screws securing the clutch cover

assembly to the flywheel for single plate clutch

ref. (fig.1).

5. DISMANTLING

a) Gently pierce out (by drilling) both end of the drive

strap rivet and remove pressure plate from the

cover assembly.

NOTE:

1. Ensure that the hole on the pressure plate

and cover are not damaged.

2. Before doing drilling of operating clamp the

job should be hold properly to avoid

movement.

Use service fixture as shown in the figure

to do the assembly of pressure plate and

drive strap. Use press to rivet the drive strap

and pressure plate securely.

b) Pierce out (by drilling) cover rivets and remove

pressure plate sub assembly.

c) Then gently pierce out (by drilling) delta rivet

riveted head and remove diaphragm.

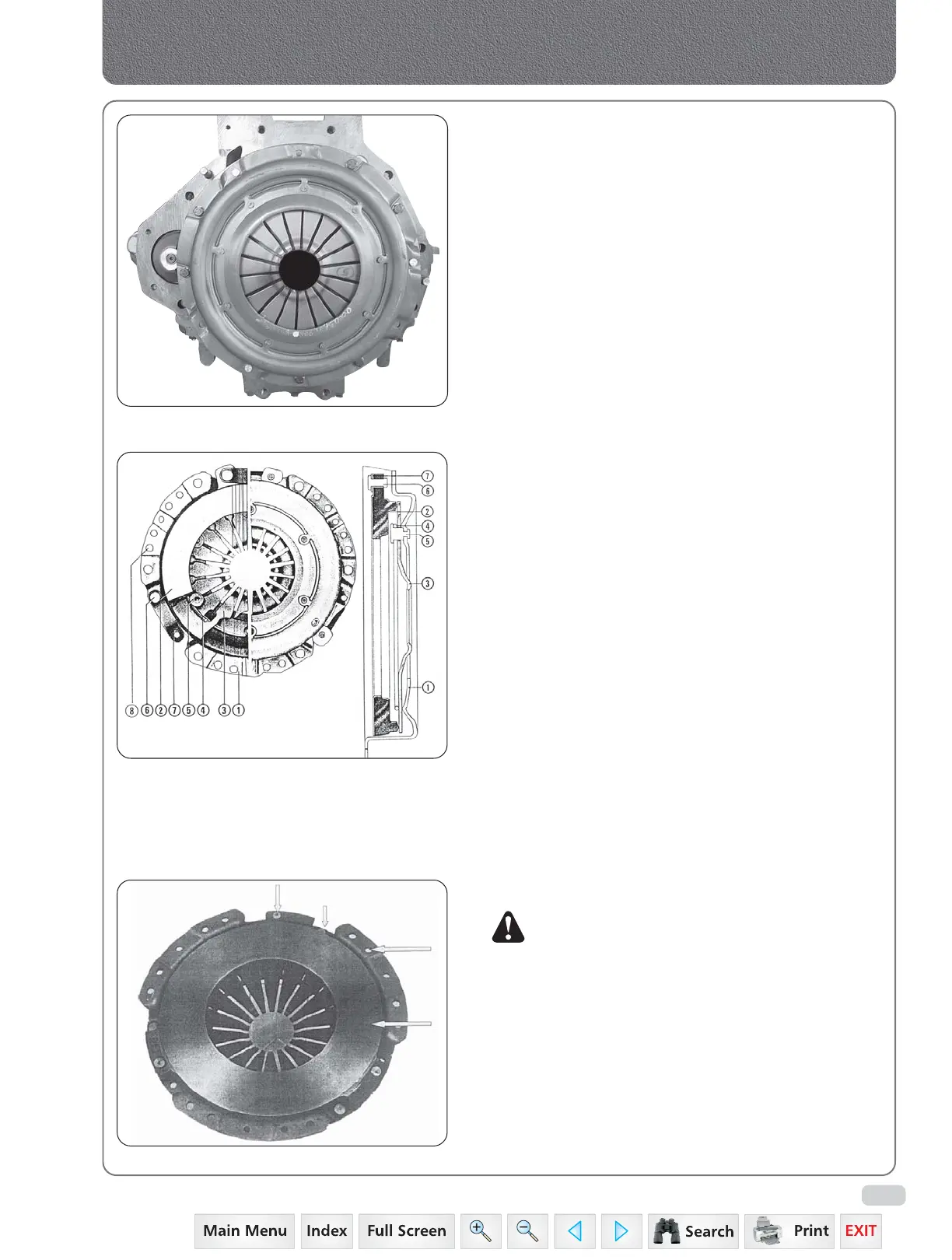

Fig. 2

1. Clutch housing 5. Pin

2. Pressure plate 6. Pivot

3. Diaphragm spring 7. Tangential drive strap

4. Ring 8. Balance hole

Loading...

Loading...