6 ENGLISH

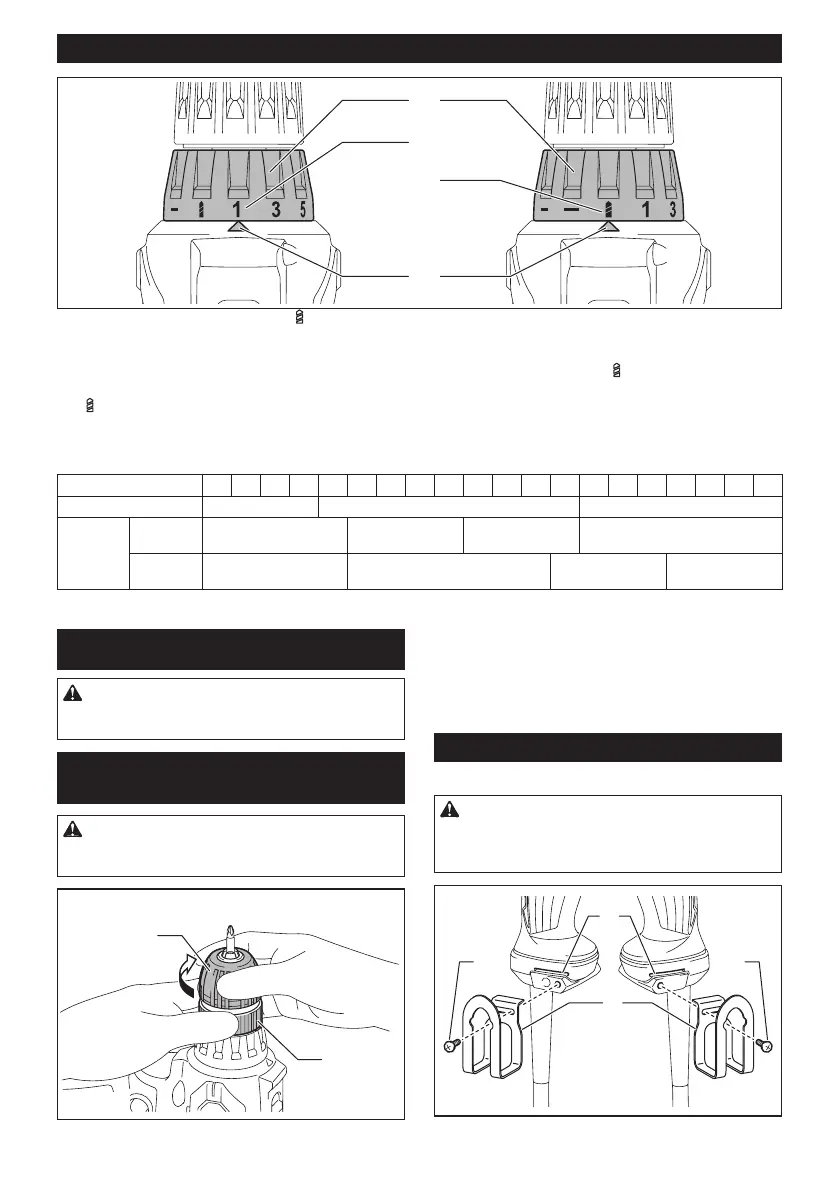

Adjusting the fastening torque

1

3

2

4

►1.Adjustingring2. Graduation 3. marking 4. Arrow

Thefasteningtorquecanbeadjustedin21levelsbyturningtheadjustingring.Alignthegraduationswiththearrow

on the tool body. You can get the minimum fastening torque at 1 and maximum torque at

marking.

The clutch will slip at various torque levels when set at the number 1 to 20. The clutch does not work at

the marking.

Before actual operation, drive a trial screw into your material or a piece of duplicate material to determine which

torque level is required for a particular application.

The following shows the rough guide of the relationship between the screw size and graduation.

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Machine screw M4 M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ɸ3.5 x 22 ɸ4.1 x 38 –

Hard wood

(e.g. lauan)

– ɸ3.5 x 22 ɸ4.1 x 38 –

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and unplugged before adjusting or

checking function on the tool.

Installing or removing driver bit/

drill bit

CAUTION: After inserting the driver bit/drill bit,

makesurethatitisrmlysecured.Ifitcomesout,do

not use it.

2

3

1

►1. Tighten 2. Sleeve 3. Ring

Hold the ring and turn the sleeve counterclockwise to

openthechuckjaws.Placethedriverbit/drillbitinthe

chuckasfarasitwillgo.Holdtheringrmlyandturn

the sleeve clockwise to tighten the chuck.

To remove the driver bit/drill bit, hold the ring and turn

the sleeve counterclockwise.

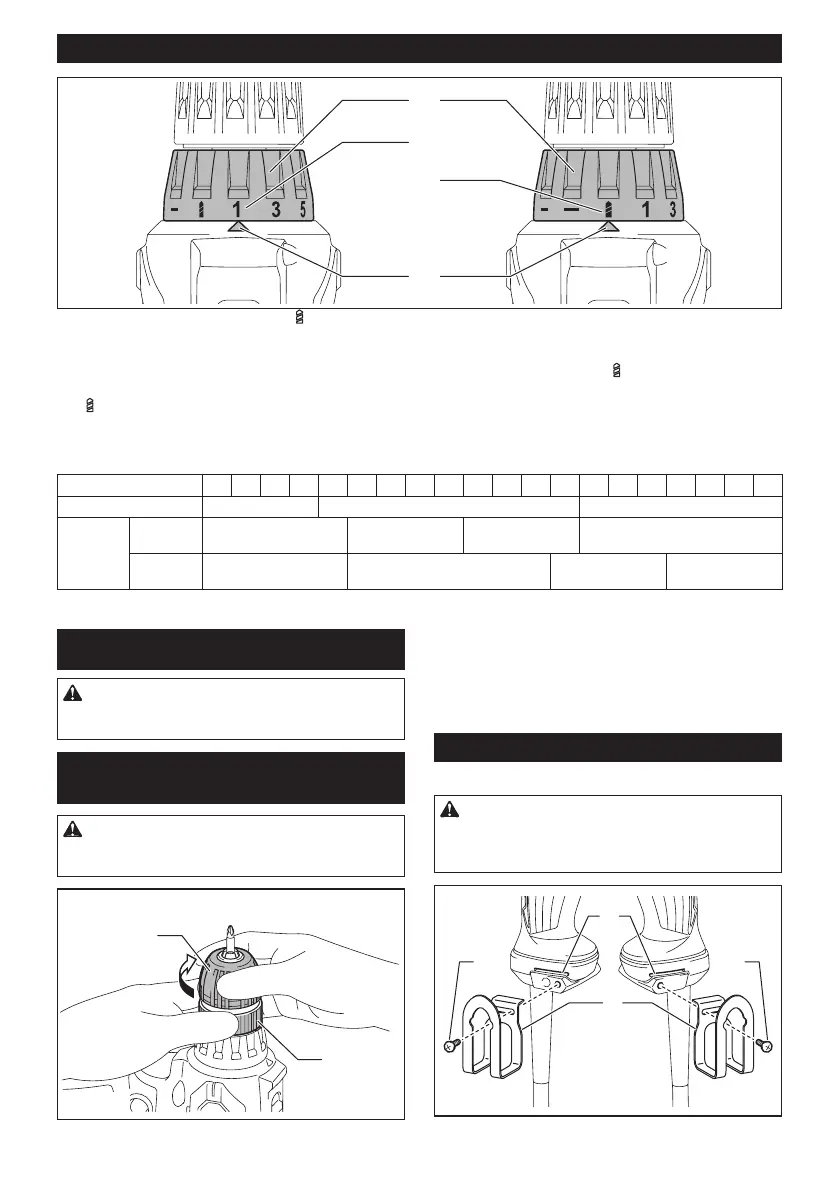

Installing hook

Optional accessory

CAUTION: When installing the hook, always

secure it with the screw rmly. If not, the hook

may come off from the tool and result in the personal

injury.

1

33

2

►1. Groove 2. Hook 3. Screw

Loading...

Loading...