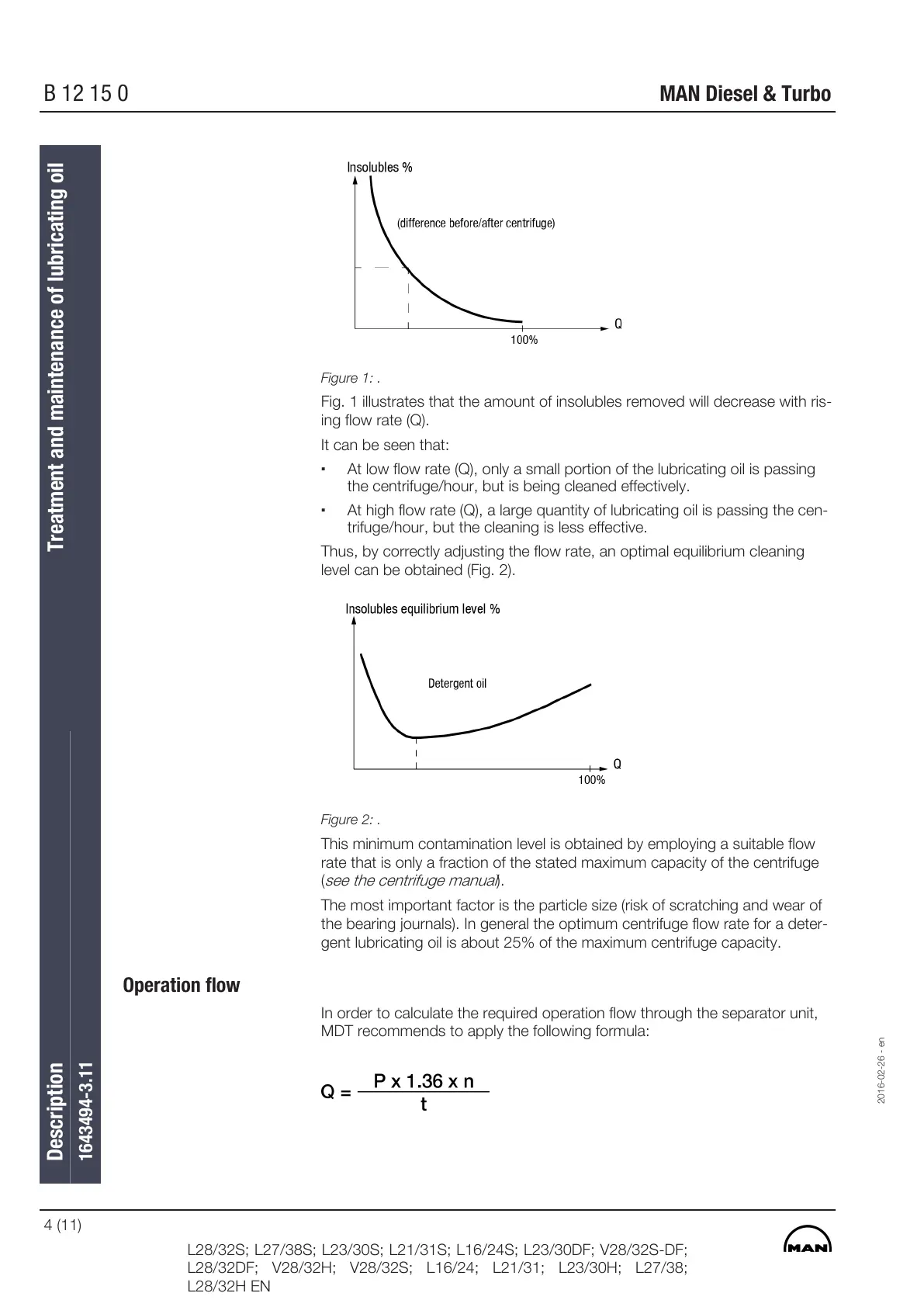

Figure 1: .

Fig. 1 illustrates that the amount of insolubles removed will decrease with ris-

ing flow rate (Q).

It can be seen that:

▪ At low flow rate (Q), only a small portion of the lubricating oil is passing

the centrifuge/hour, but is being cleaned effectively.

▪ At high flow rate (Q), a large quantity of lubricating oil is passing the cen-

trifuge/hour, but the cleaning is less effective.

Thus, by correctly adjusting the flow rate, an optimal equilibrium cleaning

level can be obtained (Fig. 2).

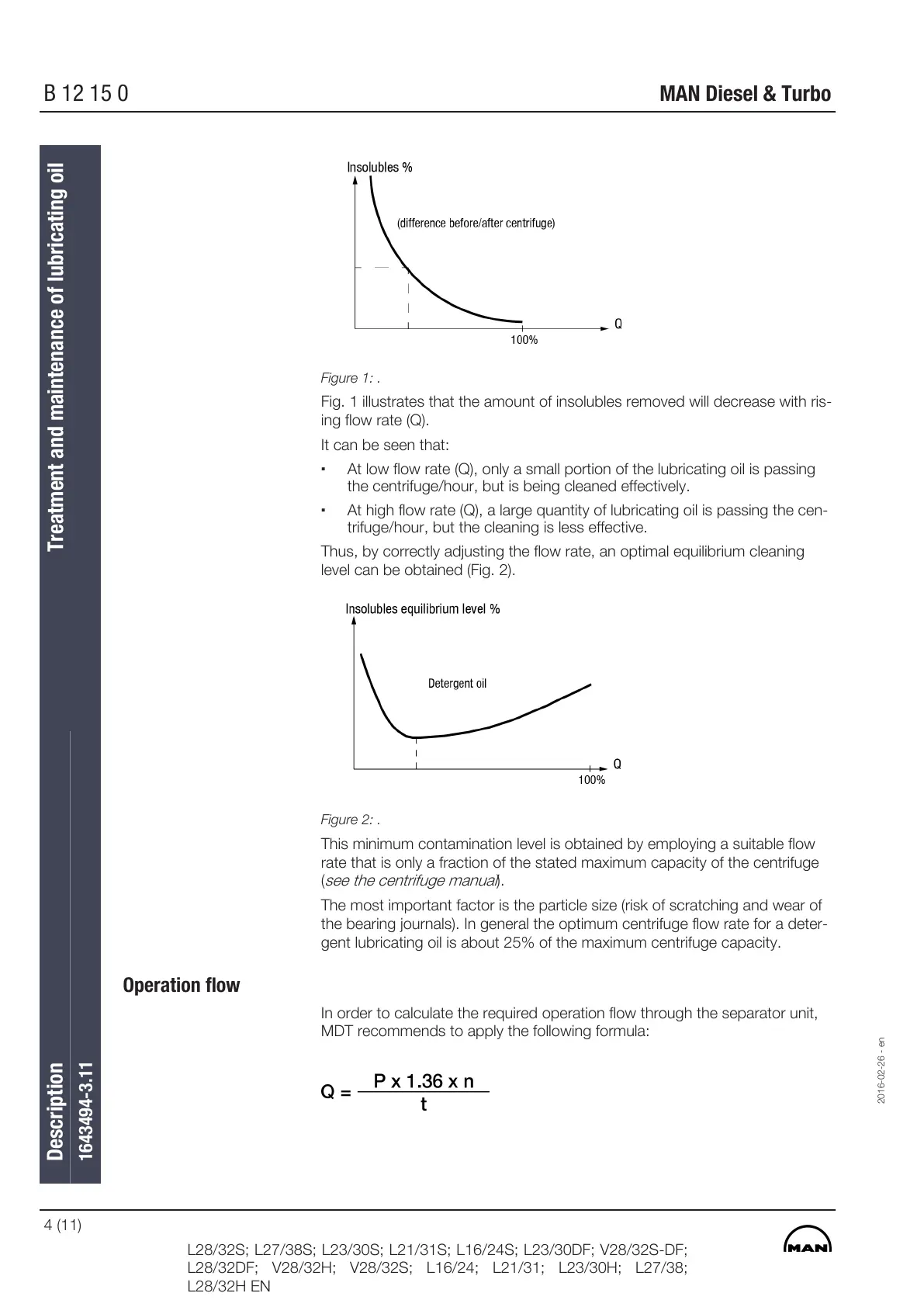

Figure 2: .

This minimum contamination level is obtained by employing a suitable flow

rate that is only a fraction of the stated maximum capacity of the centrifuge

(

see the centrifuge manual

).

The most important factor is the particle size (risk of scratching and wear of

the bearing journals). In general the optimum centrifuge flow rate for a deter-

gent lubricating oil is about 25% of the maximum centrifuge capacity.

Operation flow

In order to calculate the required operation flow through the separator unit,

MDT recommends to apply the following formula:

Description

Treatment and maintenance of lubricating oil

1643494-3.11

2016-02-26 - en

B 12 15 0

MAN Diesel & Turbo

4 (11)

L28/32S; L27/38S; L23/30S; L21/31S; L16/24S; L23/30DF; V28/32S-DF;

L28/32DF; V28/32H; V28/32S; L16/24; L21/31; L23/30H; L27/38;

L28/32H EN

Loading...

Loading...