V

A

V

B

IMPACT

REBOUND

TIME

VELOCITIES

2.2 Leeb Hardness Testing Principle

An impact body with a spherical test tip made of tungsten carbide is

propelled against the sample surface by a spring force and then

rebounds back. At a distance of 1mm from the sample surface, the

impact and rebound velocity of the impact body are measured by the

following method: A permanent magnet embedded in the impact body,

when passing through the coil in its coil holder, induces in the coil an

electric voltage proportional to the velocities of the magnet. Leeb

hardness is expressed by the following formula:

HL=1000×(V /V )

B A

Where: HL is Leeb Hardness

V is the rebound velocity of the impact body

B

V is the impact velocity of the impact body

A

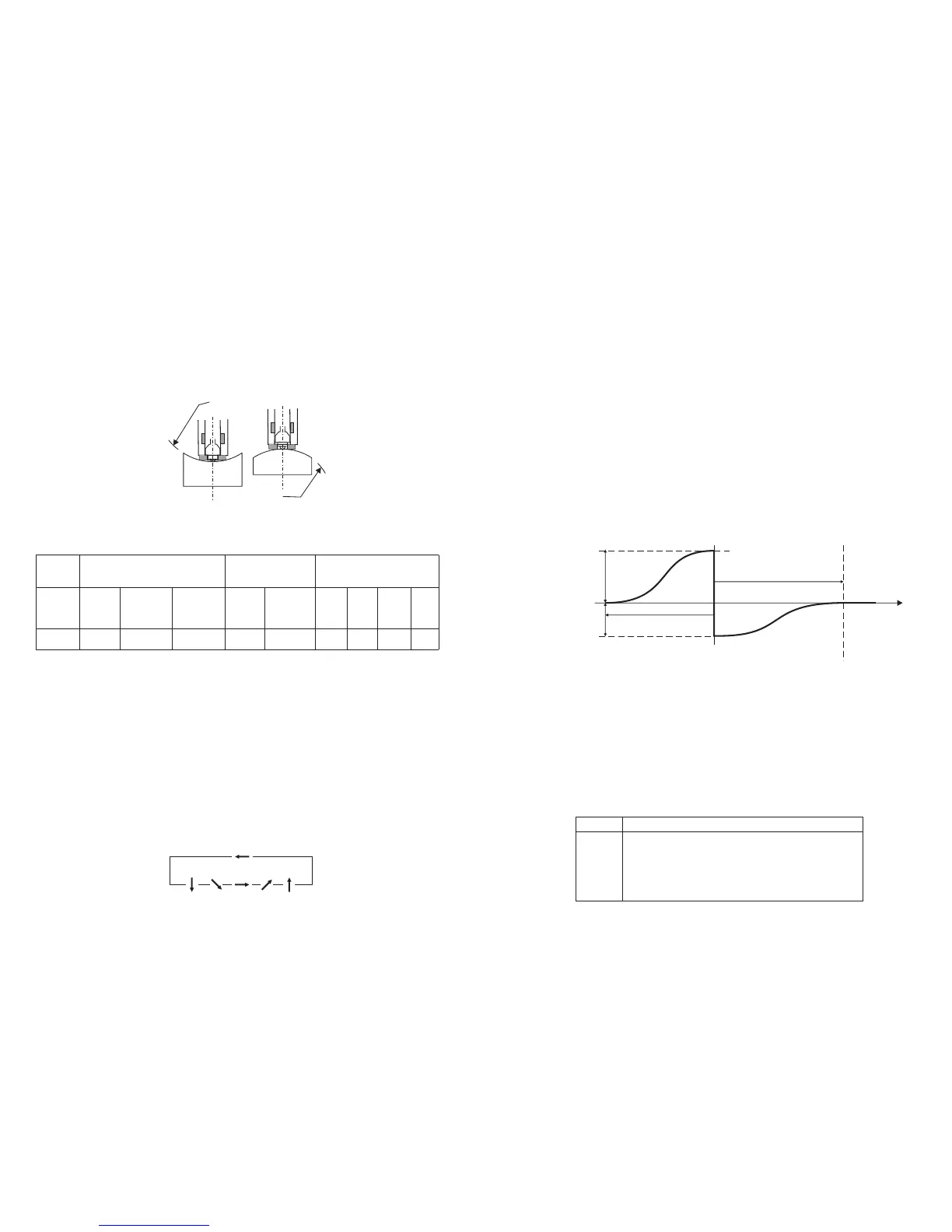

The voltage characteristic of output signal, when the impact body

passes through the induction coil is illustrated in the following figure:

Voltage Characteristic of output signal

A Leeb’s Hardness Tester measures the hardness of sample material in

terms of Hardness Leeb (HL), which can be converted into other

Hardness units (Rockwell B and C, Vicker, Brinell and Shore D).

When measuring the hardness of a sample material using the traditional

static hardness testing method, a change of applied pressure will result

in a change in the hardness reading. This will also happen during a

Leeb’s Hardness test when you change the impact device. In measuring

the hardness of the same test sample with different impact devices, the

Leeb’s hardness values obtained will vary.

For Example: 760 HLD≠760HLC≠760HLG

2.3 Symbols and illustrations of hardness scale

Fig 2.4

Symbols

Illustrations

Leeb hardness value used with impact device D

Brinell hardness value

Rockwell B hardness value

Rockwell C hardness value

Shore hardness value

Vicker hardness value

LD

HB

HRB

HRC

HSD

HV

4

R

R

3.5 Samples with Curved Surfaces

The larger the curvature of the workpiece’s surface, the easier the

testing operation. Under normal conditions, testing can be done directly

with the standard support ring to a curvature with radius of 1 3/16”

(30mm) or longer.

For a workpiece with a radius of less than 1 3/16” (30mm), a special

support ring should be used for testing.

For impact device type D , R =30mm

min

3.6 Test Sample Properties

Table 3.1

4 Operation of the tester

4.1 Power on/off

* Press the POWER/MENU key, now power is on. The instrument is in

working mode.

* The LCD will display the same settings that were previously set. If the

display meets your current testing requirements, you can start the test

immediately. If not, you can enter your required settings using the

keypad.

* The tester can be turned off by pressing the POWER/MENU key for 3

seconds while OFF shows on the display.

4.2 Setting your Impact Direction

Use the DIR/SHIFT button to move the cursor until you reach the desired

direction.

Press DIR/SHIFT key

Sample

Impact

Device

D

Needs

Support

Needs to

be

stabilized

No stren-

gthening

needed

Sample Weight

(kg)

Min. Thickness

(mm)

Sample

Hardened

layer

ISO Ra Rz

Max. Roughness

(or Min. Fineness)

0.05-2 2.5 >5 3 0.8

N7

2µm 10µm

∇6

7

Fig 3.2

Fig 3.2

Loading...

Loading...