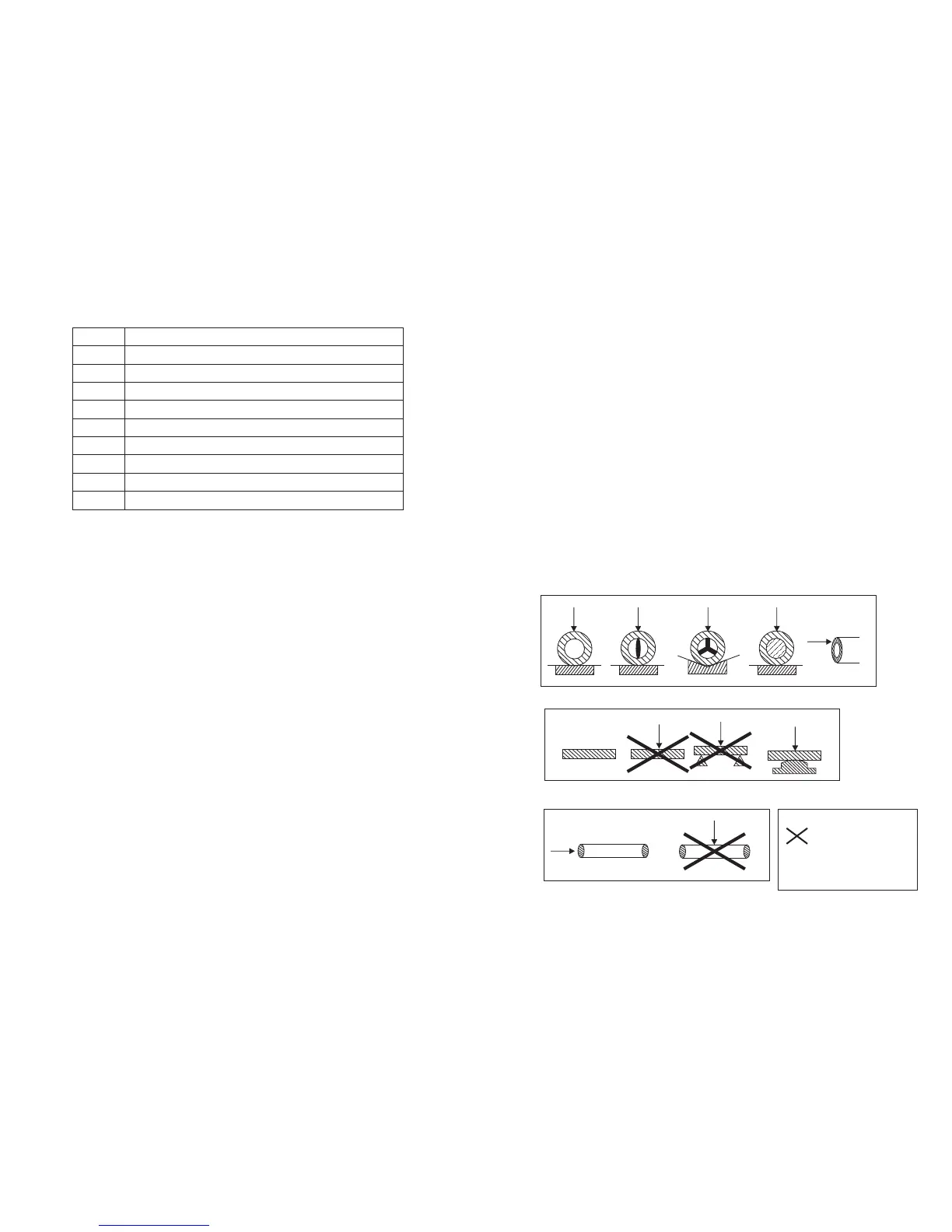

2.4 Symbols of materials

Symbol Illustrations

1 Steel and cast steel

2 Cold work tool steel

3

Stainless steel and high temperature-resistant steel

4 Cast iron with lamellar graphite (grey cast iron GG)

5 with spheroidal and nodular graphite (GGG)Cast iron

6 Cast aluminum alloys

7 Copper - zinc alloys (brass)

8 Copper-alu /copper-tin alloys (bronze)

9 Copper

3 Preparation

Selection of the workpiece to be tested and preparation of its surface

prior to testing will help insure accuracy. Magnetism of the sample itself

should be avoided. The surface temperature of sample should be less

than 120 °C.

3.1 Weight Requirement

To achieve correct test results, select thick, heavy, and solid workpieces

for testing whenever possible. The surface area where the impact body

strikes should have an even hardness.

A solid workpiece that weighs more than 11lbs. (5Kg) can be tested on

directly with the this hardness testers. Support is not necessary for

heavy sample.

A workpiece that weighs 6 to 11lbs. (3 to 5Kg) should be fixed to a

bearing or support weighing over 11lbs (5kg) to avoid bending,

deformation, and displacement during testing.

A workpiece that weighs less than 4 lbs. (2Kg) should be secured to a

workbench or a stable support. The surface between the workpiece and

the support must be hard, clean, and smooth. To secure the workpiece,

apply petroleum jelly or yellow grease to the adjoining surfaces of the

workpiece and support, press the workpiece firmly onto the support, and

eliminate any air between the two surfaces by moving the workpiece

back and forth.

Proper coupling requires a little experience. Insufficiently coupled

samples produce large variations of individual measurements, HL-

values which are too low and the operation is characterized by a rattling

noise upon impact of the test tip.

For the coupling operation, the following prerequisites must be fulfilled:

* The contact surface of the sample and the surface of the base

plate must be flat, plane parallel and ground.

* The direction of the test impact must be perpendicular to the coupled

5

surface.

* Minimum thickness of the sample for coupling (3mm).

3.2 Roughness Requirement

To eliminate measurement errors which could result from the roughness

of the test surface, the surface should be polished so that a metallic

luster appears. The roughness (Ra) of the surface must be limited to ≤

2µm. Note that the rougher the surface of the workpiece, the lower the

hardness test results.

3.3 Cleanliness Requirements

To ensure test accuracy, the test surface of the workpiece must be clean

and free of any oil stains, rust, and remains from electro-plating or paint.

3.4 Stability Requirements

To avoid displacement during testing, the workpiece should be firmly

fixed with its test surface perpendicular to the impact direction. Due to

the impact of the Impact Body, the test area may deform or vibrate, even

for some workpieces with suitable weight and thickness.

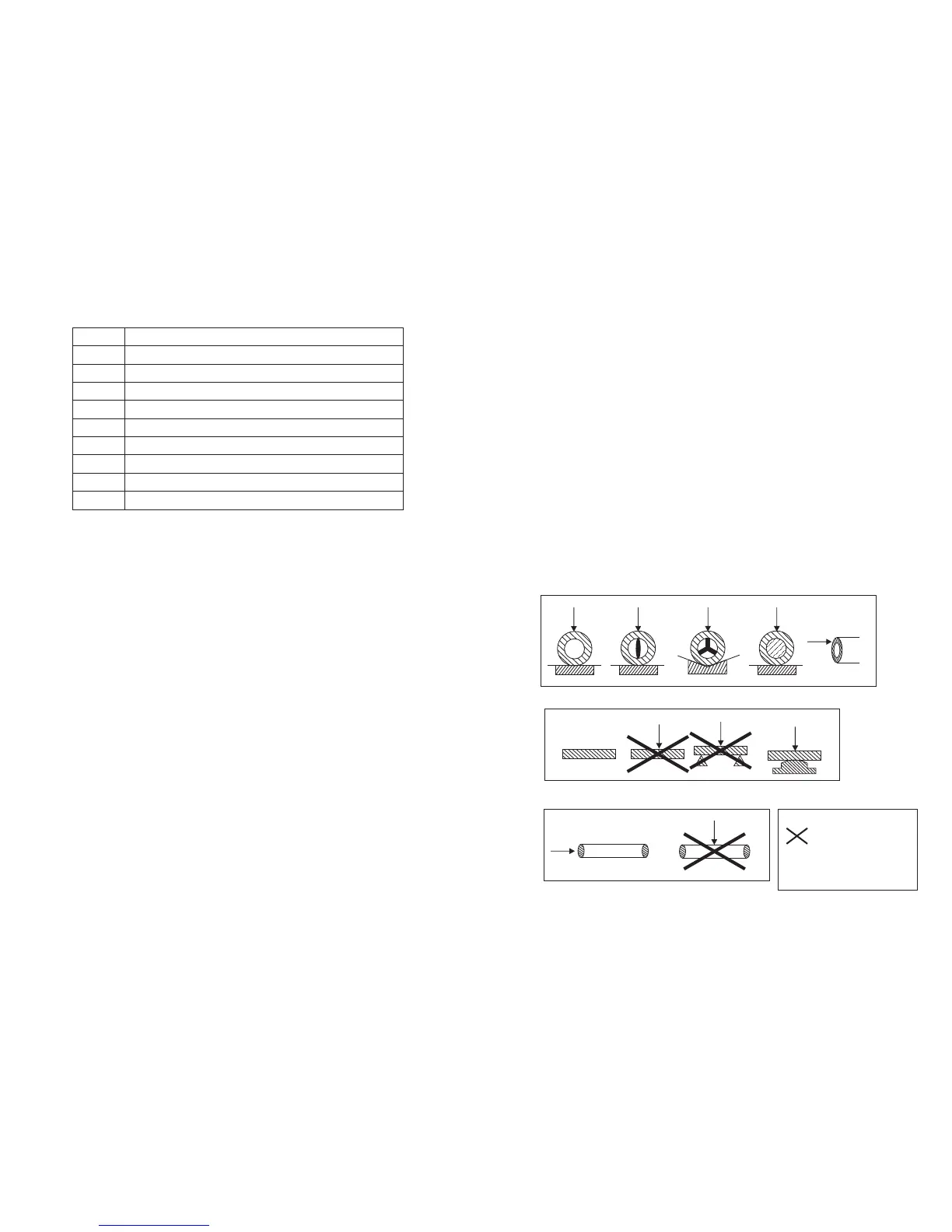

The tested hardness may be lower than normal. This is especially true

for workpieces such as a large plate, a long bar or a rod, and workpieces

with a curved surface. Some testing recommendations for these

workpieces are shown in figure 3.1

(1)PIPE

(2)PLATE

(3)ROD or LONG BAR

Note:

This indicates an

improper test.

Otherwise, test

method is accurate.

6

Fig 3.1

Loading...

Loading...