3-14

A6

A3 - Condition of the joystick bellows

CHECK

- For this operation, climb into the basket with the engine switched off.

- Check the rubber joystick bellows are in good condition, by acting as if you were

making a movement.

- The bellows must not show any crazing, cracks, risks of water penetration detracting

from the machine’s correct operation.

A4 - Condition of the wheels and tyres

CHECK

- Check the condition of the tyres to detect any cuts, tears, protuberances, wear, etc... in

the tyres.

A5 - Tightness of the wheel nuts

CHECK

- Check the tightness of the wheel nuts.

Failure to follow this instruction may lead to deterioration and breaking of the wheel

pins and to deformation of the wheels.

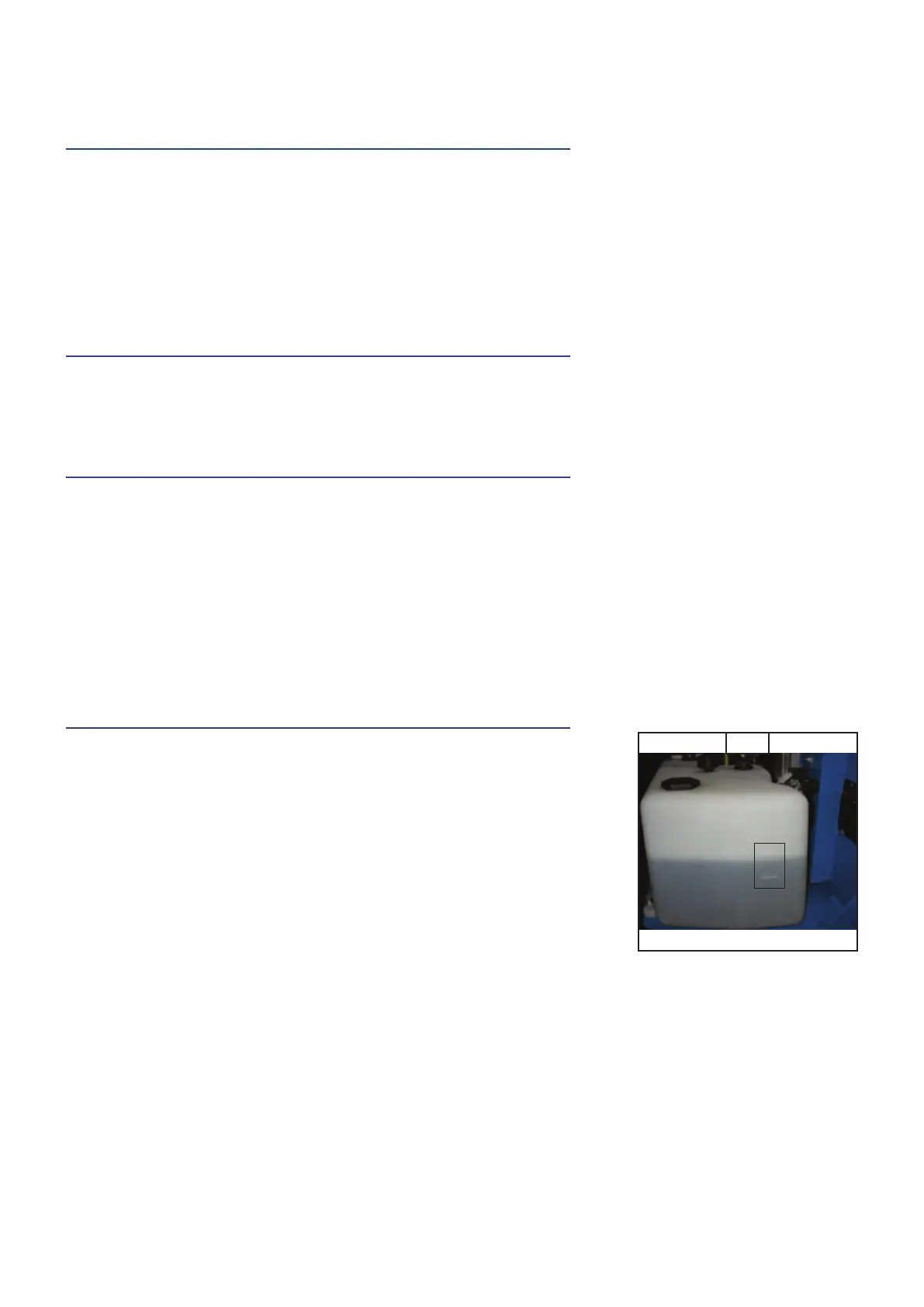

A6 - Hydraulic oil level

CHECK

- It is essential to maintain a correct level of hydraulic oil for the machine to operate

correctly. The wrong level of hydraulic oil can damage the hydraulic components. Daily

checks enable you to note any change in the oil level that may indicate the presence of

problems in the hydraulic system.

- Remark: perform this procedure with the lifting platform in the folded position and the

engine switched off.

- Visually inspect the sight glass located on the side of the hydraulic oil reservoir.

- Result: the hydraulic oil level must be at least 5 cm from the upper mark.

- Add oil if necessary.

647369 (01/03/2017)

78/100 SEC 2 / 120 SE 2

Loading...

Loading...