3 - 30

E5 - ANGLE GEAR BOX OIL

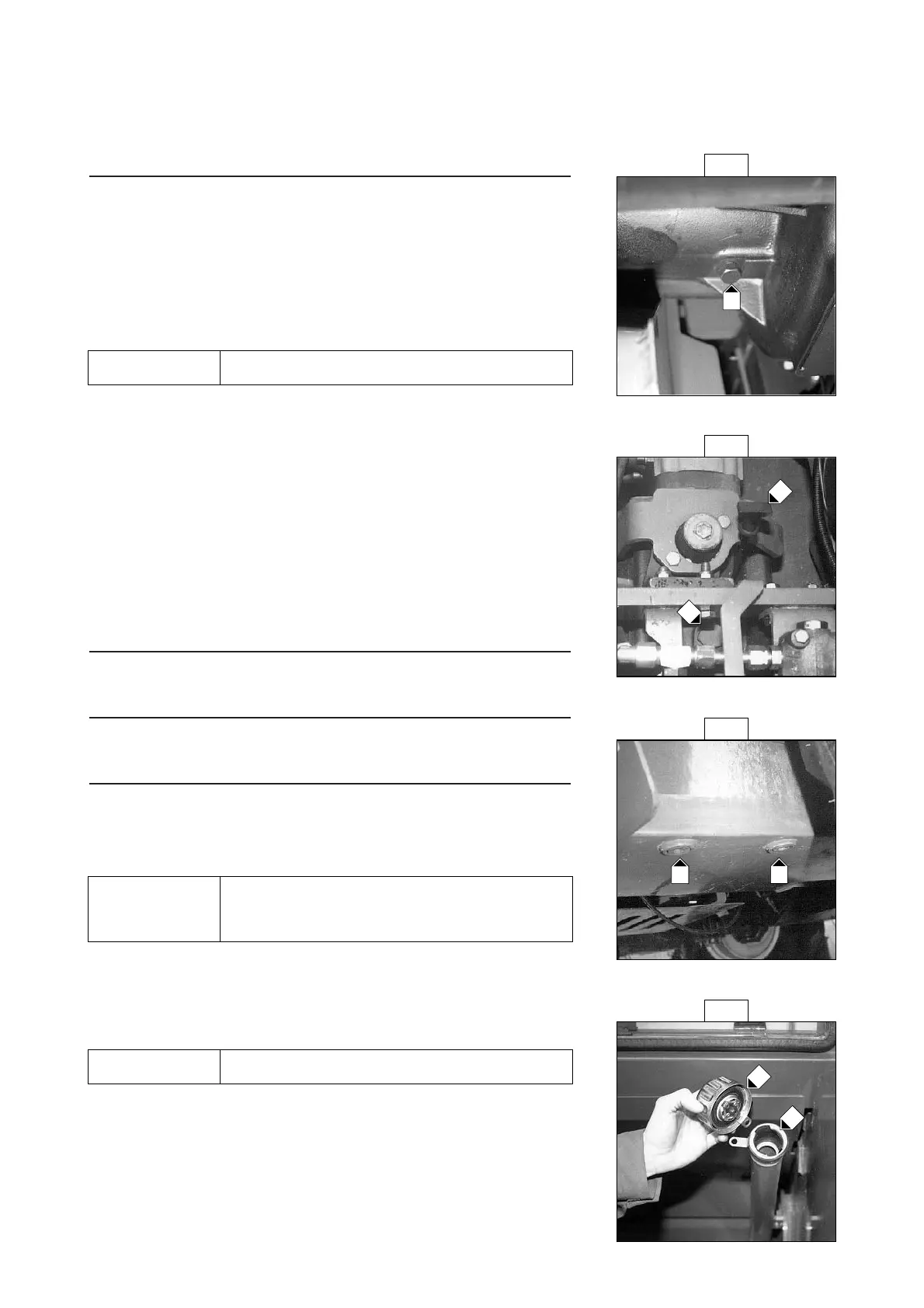

DRAIN

Place the lift truck on level ground with the I.C. engine stopped, the angle

gear box oil still warm.

- Place a container under drain plug 1 (Fig. E5/1) and unscrew the plug.

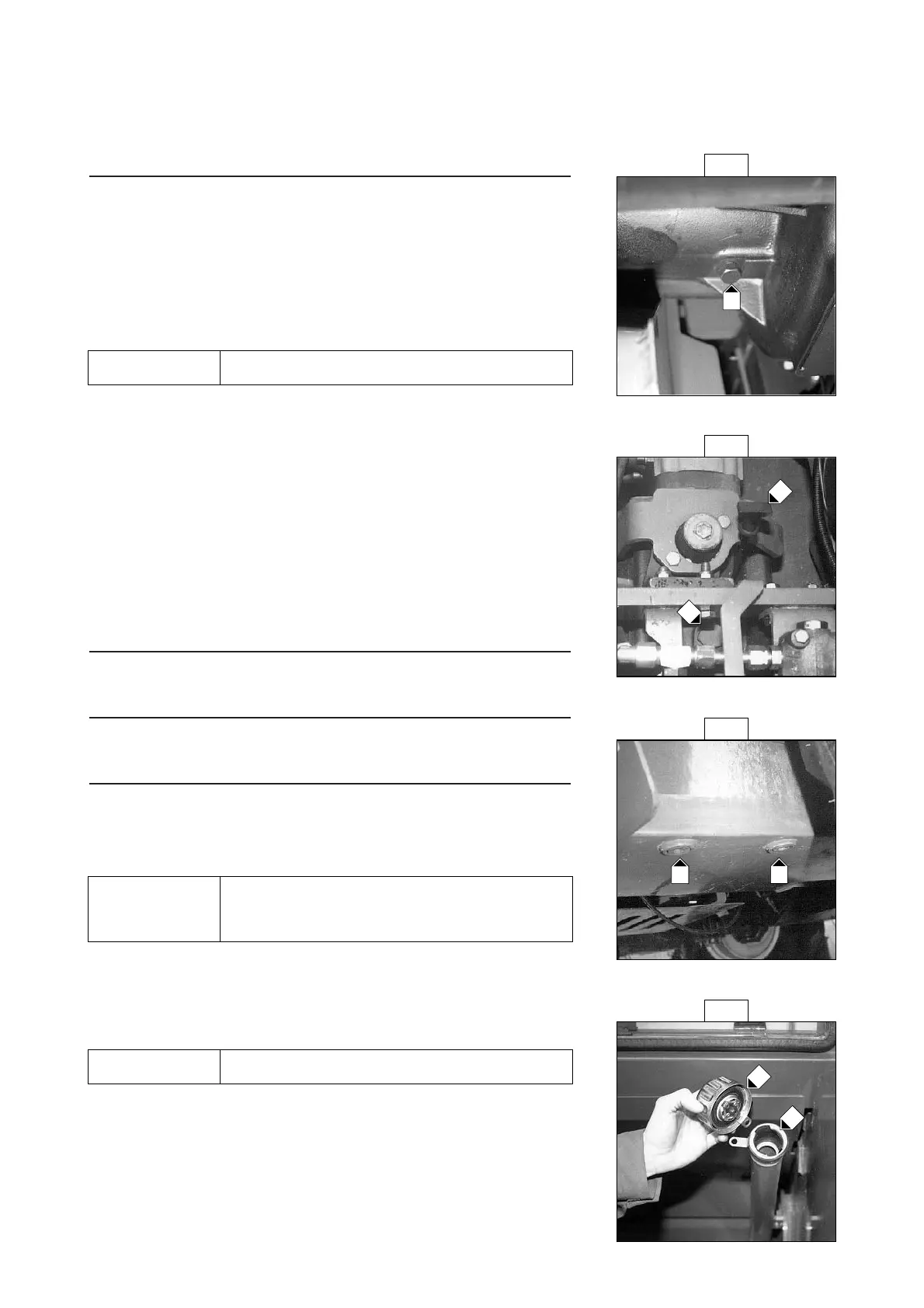

- Remove dipstick 2 (Fig. E5/2) and unscrew filler cap 3 (Fig. E5/2) in order to

ensure that the oil is drained properly.

- Refit and tighten drain plug 1 (Fig. E5/1) (Tightening torque 20 to 29 N.m or

15-21 ft/lbs).

- Fill up with oil (See LUBRICANTS AND FUEL in SECTION 3 -

MAINTENANCE) by filler port 3 (Fig. E5/2) and refit the filler cap.

- Check the correct level between the MINI and MAXI marks on dipstick 2

(Fig. E5/2).

- Check for any possible leaks at the drain plug.

E6 - H

YDRAULIC OIL

DRAIN

E7 - SUCTION STRAINER FOR HYDRAULIC OIL TANK

CLEAN

E8 - FILTER CAP FOR HYDRAULIC OIL TANK

CHANGE

Place the lift truck on level ground with the I.C. engine stopped and telescope

boom retracted and lowered as far as possible.

DRAINING THE OIL

- Place a container under drain plug 1 (Fig. E6/1) and unscrew the plug.

- Remove filler cap 2 (Fig. E6/2) in order to ensure that the oil is drained

properly.

CLEANING THE STRAINER

- Remove suction cover 3 (Fig. E6/3).

- Remove and clean the strainer using a compressed air jet, check its

condition and replace if necessary (See FILTERS CARTRIDGES AND

BELTS in SECTION 3 - MAINTENANCE).

- Refit the strainer and tighten the suction cover 3 (Fig. E6/3) (Tightening

torque 81 N.m or 60 ft/lbs) making sure the seal is in the correct position.

E5/1

E5/2

1

3

2

E6/1

E6/2

2

4

1

1

Dispose the drain oil in an ecological manner.

IMPORTANT

Before any intervention, thoroughly clean the area

surrounding the drain plugs and the suction cover on

the hydraulic tank.

IMPORTANT

Dispose the drain oil in an ecological manner.

IMPORTANT

Loading...

Loading...