3 - 31

D12

1

1

1

2

3

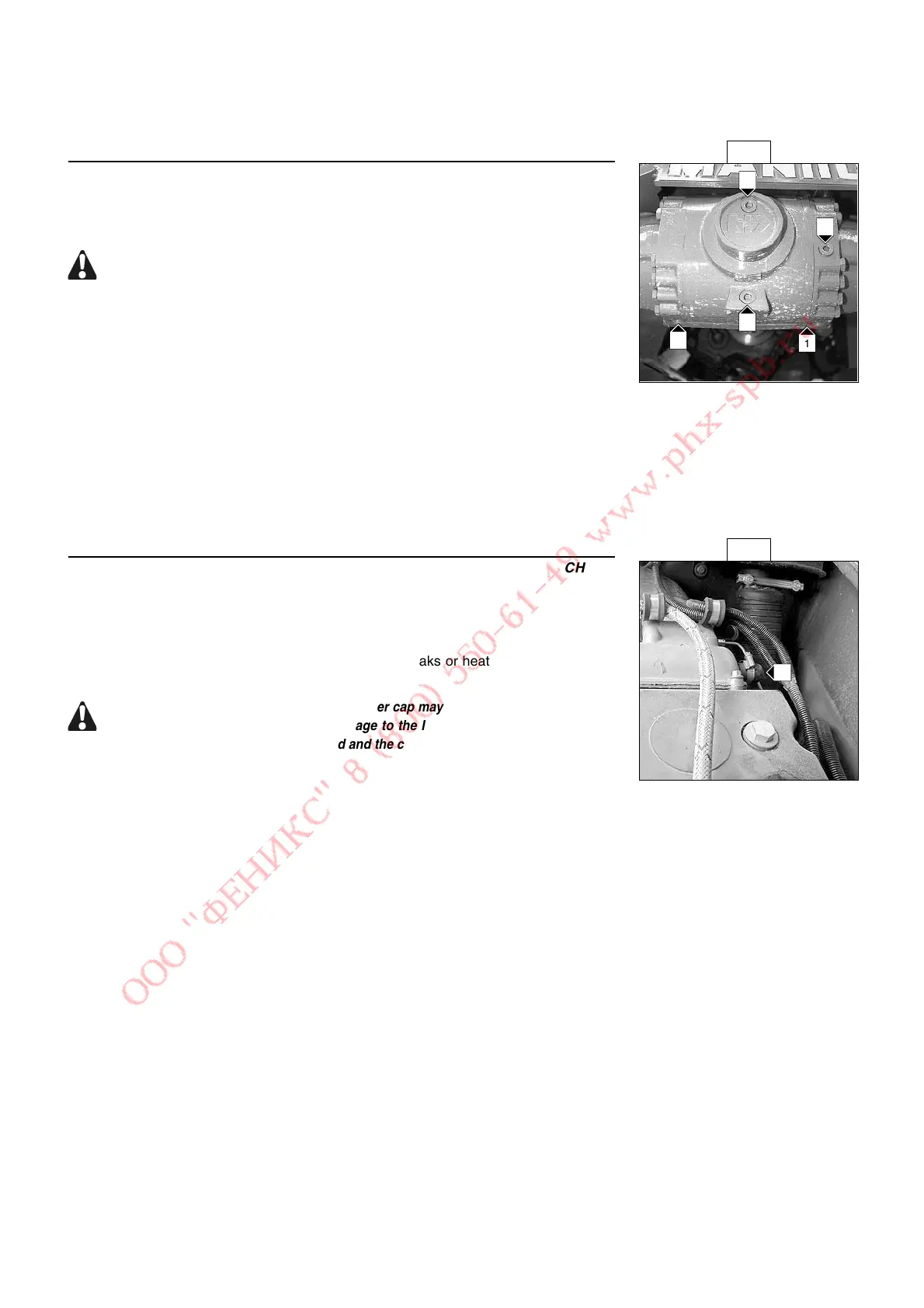

D12 - FRONT AND REAR AXLE DIFFERENTIAL OIL

DRAIN

Place the lift truck on level ground with the engine stopped and the differential oil still

warm.

Dispose the drain oil in an ecological manner.

- Place a container under drain plugs 1 (Fig. D12) and unscrew the plugs.

- Remove level plug 2 (Fig. D12) and filler plug 3 (Fig. D12) in order to ensure that the

oil is drained properly.

- Refit and tighten drain plugs 1 (Fig. D12) (Tightening torque 34 to 49 N.m).

- Fill up with oil (See chapter : LUBRICANTS AND FUEL in paragraph : 3 -

MAINTENANCE) by filler port 3 (Fig. D12).

- The level is correct when the oil level is flush with the edge of port 2 (Fig. D12).

- Check for any possible leaks at the drain plugs.

- Refit and tighten level plug 2 (Fig. D12) (Tightening torque 34 to 49 N.m) and filler plug

3 (Fig. D12) (Tightening torque 34 to 49 N.m).

- Repeat this operation for the rear axle differential.

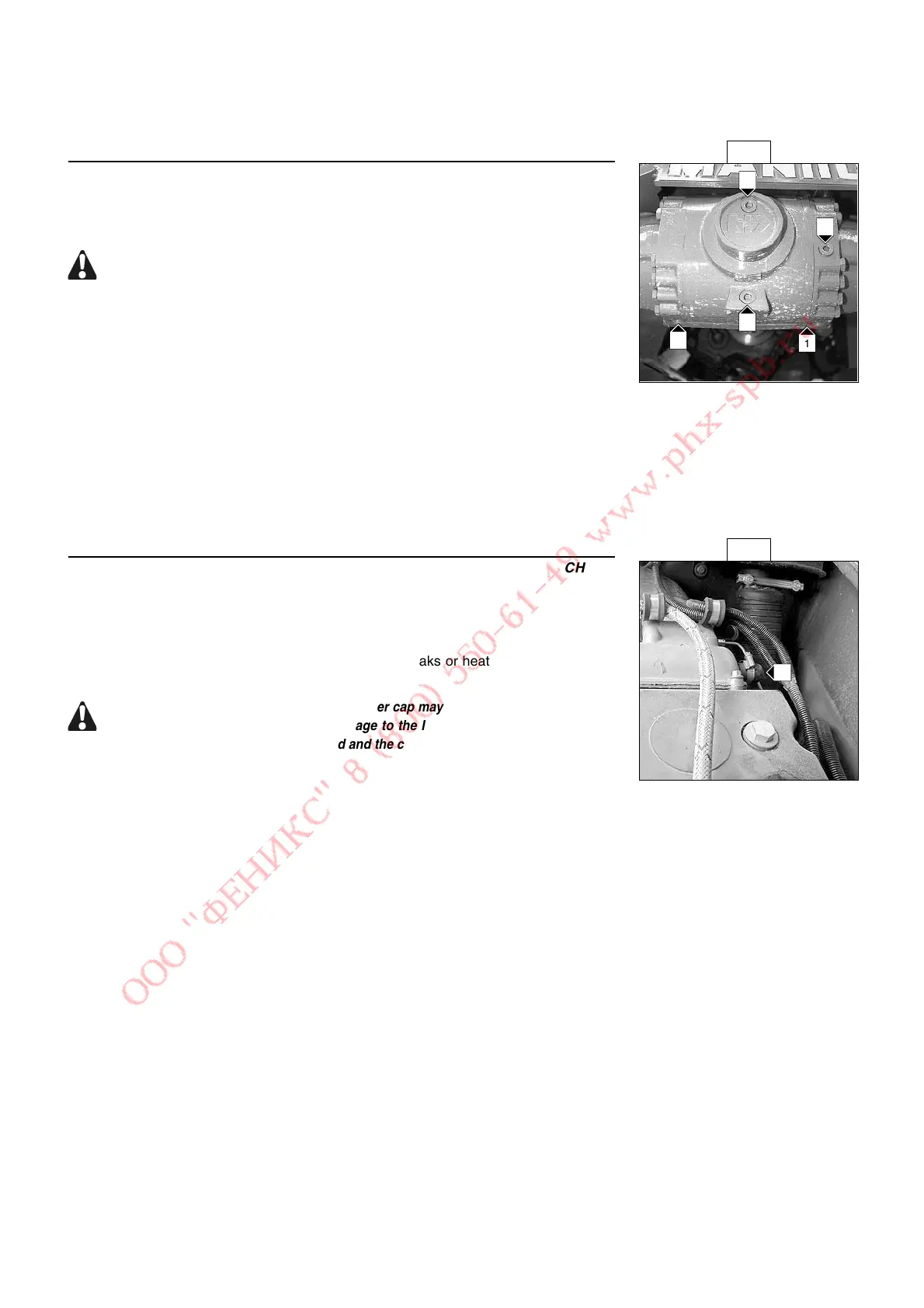

D13 - BLANKING CAP ON THE INDUCTION MANIFOLD

CHECK

MLT 629/730 Série A

MT 732/932 Série A

(Only for I.C. Engine AR 81026 up to serial Nr U 170804 H)

If the cap on the induction manifold 1 (Fig. D13) have craks or heat damage, renew the

cap immediately.

Failure to change a cracked or damaged rubber cap may cause the entry of air that is

not filtered, this can result in severe damage to the I. C. engine. If any other type of

cap is found to be fitted, it is to removed and the correct cap fitted immediately.

D13

1

Loading...

Loading...