3-18

C - EVERY 250 HOURS SERVICE

Carry out the operations described previously as well as the following operations.

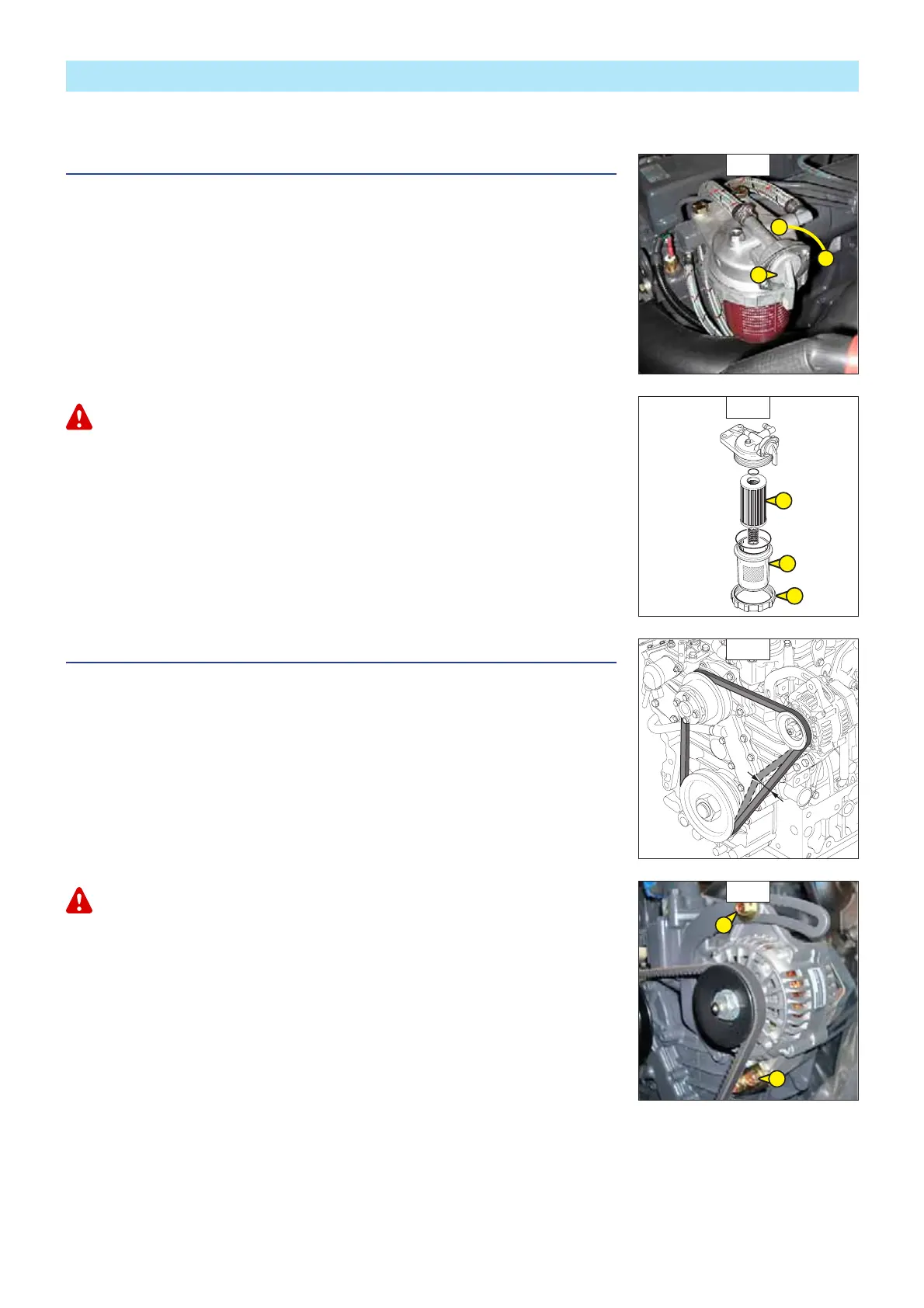

C1 - FUEL FILTER

CLEAN

- Lift up the overhead guard or the cab (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

- Close the fuel valve 1 (fig. C1/1) by setting to position B.

- Carefully clean the outside of the pre-filter and its holder, to prevent dust from getting into

the system.

- Unscrew the retaining ring 2, remove the housing 3 (fig. C1/2) and clean the inside using

a brush immersed in clean diesel oil.

- Remove the cartridge filter 4 (fig. C1/2) and dip in diesel oil to rinse.

- Reassemble the unit.

- Open the fuel valve 1 (fig. C1/1) by setting to position A.

- Bleed the fuel circuit (see: 3 - MAINTENANCE: G1 - FUEL SYSTEM).

Dust and impurities in the fuel will cause the injection pump and injectors to wear more quickly. To avoid

this, regularly clean the fuel filter housing.

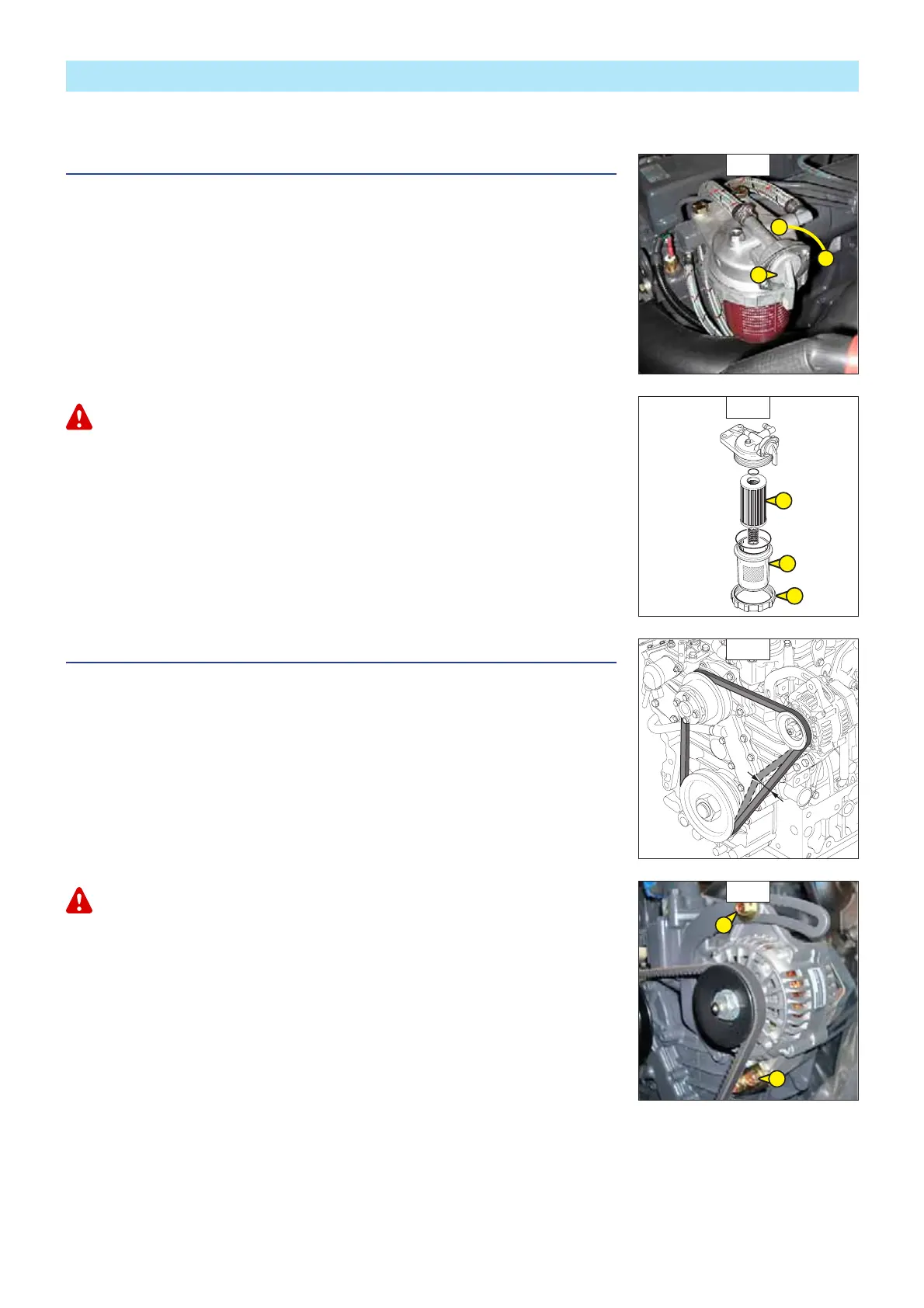

C2 - ALTERNATOR/FAN/CRANKSHAFT BELT TENSION

CHECK - ADJUST

- Lift up the overhead guard or the cab (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

- Check the belt for signs of wear and cracks and change if necessary (see: 3 - MAINTENANCE:

FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the crankshaft and of the alternator.

- Under pressure applied by the thumb (98 N), the tension should be between 7 and 9 mm

(fig. C2/1).

- Carry out adjustments if necessary.

- Untighten screws 1 (fig. C2/2) by two to three thread turns.

- Swivel the alternator assembly so as to obtain the belt tension required.

- Retighten screws 1 (fig. C2/2).

If the alternator belt has to be changed, check the tension again after the first 20 hours of operation.

C1/1

A

B

1

C2/1

C1/2

4

3

2

C2/2

1

1

Loading...

Loading...