Operating Manual

PR-050823-0121 Version 161109 9 of 14

Flange connection

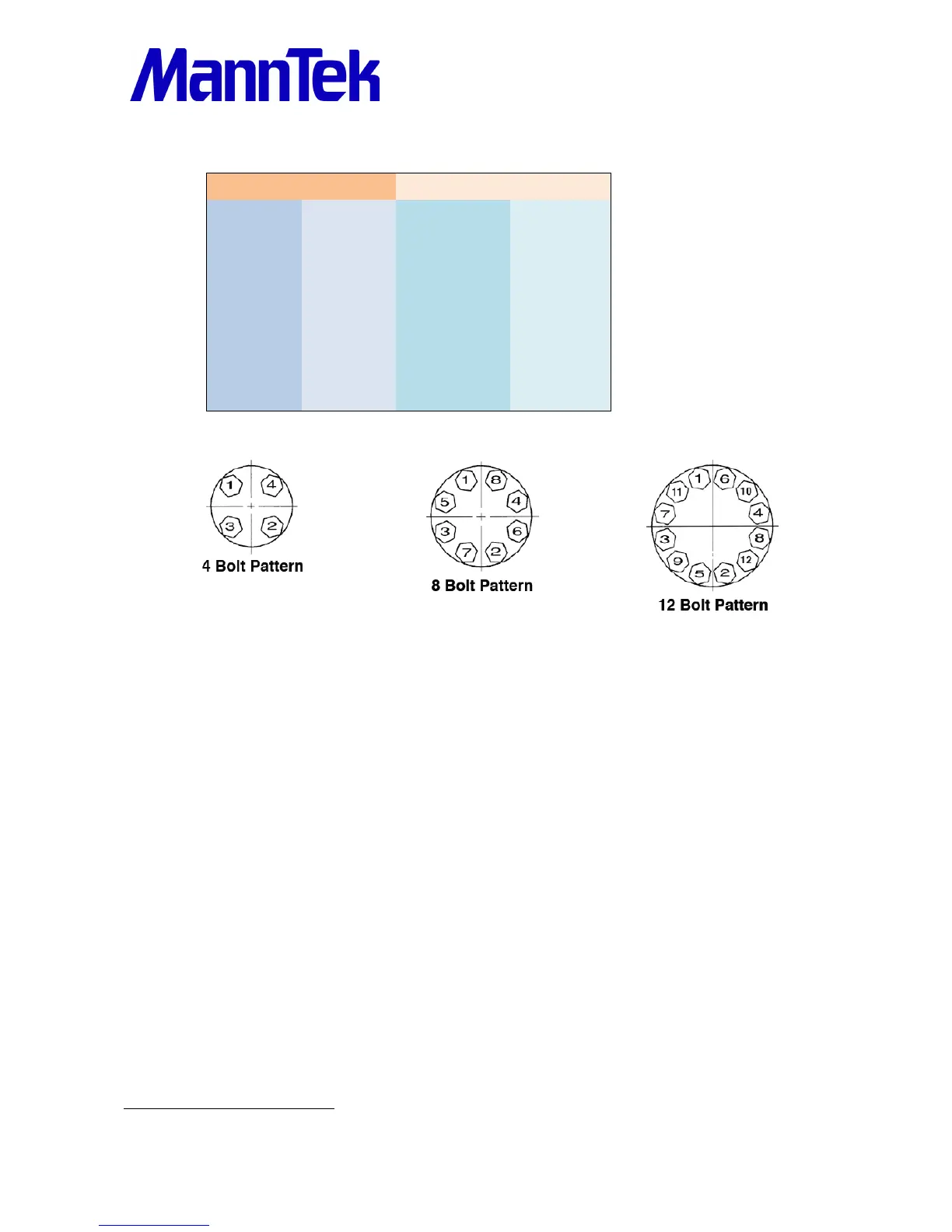

a. Table 6: Tightening torque

1

for bolts:

Metric Inch

Size 8.8 Size A193 B7

M8 24 Nm 5/16 -18 UNC 16 lbf-ft

M10 50 Nm 3/8 -16 UNC 29 lbf-ft

M12 85 Nm 1/2 -13 UNC 70 lbf-ft

M16 210 Nm 5/8 -11 UNC 139 lbf-ft

M20 410 Nm 3/4 -10 UNC 243 lbf-ft

M22 550 Nm 7/8 -9 UNC 389 lbf-ft

M24 700 Nm 1 -8 UNC 582 lbf-ft

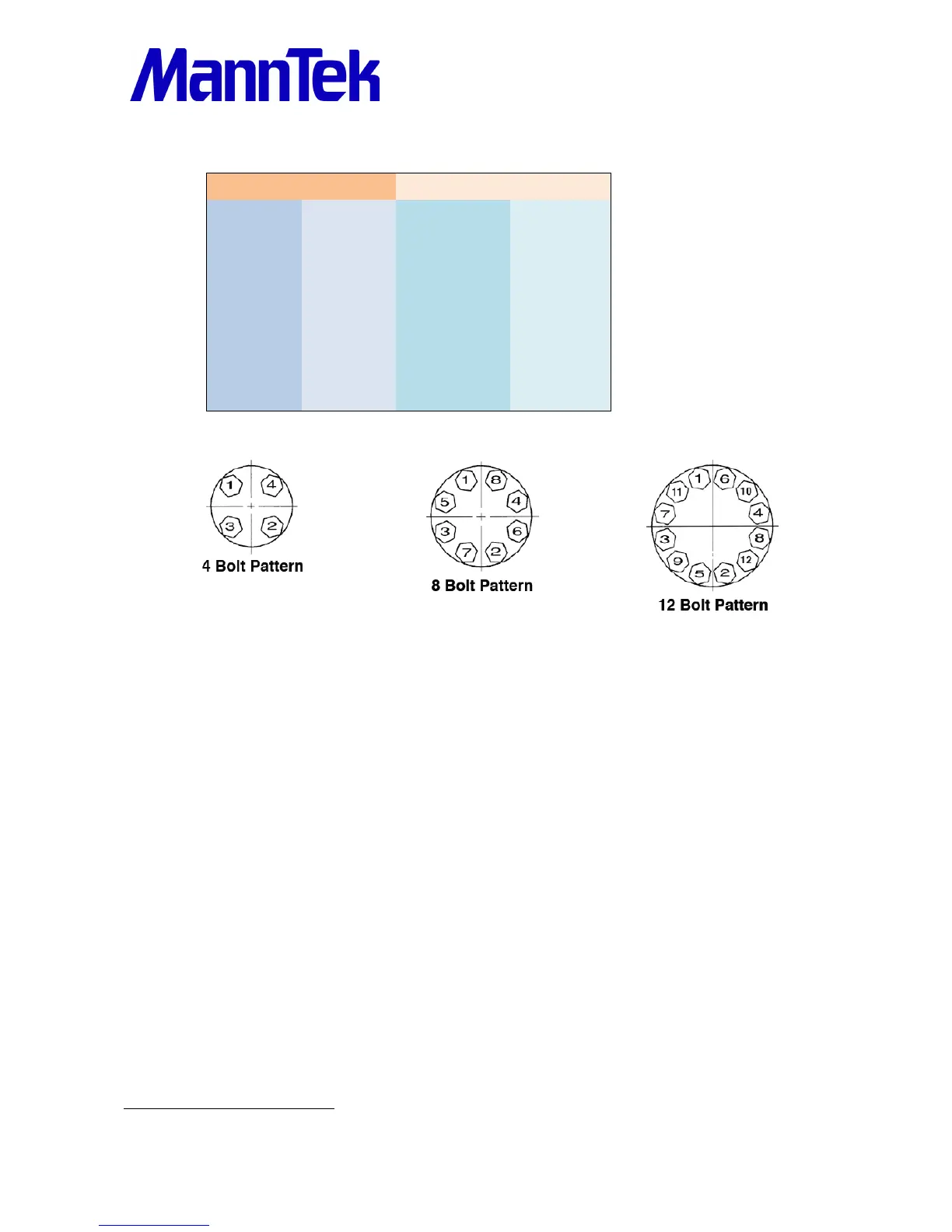

a. Bolt tightening sequence.

NPT thread connection

Sealing NPT threads can be an exasperating experience if certain techniques are not followed.

The following tips will help alleviate many common problems in thread sealing:

b. Always use some type of sealant (tape or paste) and apply sealant to male thread only. If using a hydraulic sealant,

allow sufficient curing time before system is pressurized.

c. When using tape sealant, wrap the threads in a clockwise motion starting at the first thread and, as layers are

applied, work towards the imperfect (vanishing) thread. If the system that the connection being made to cannot

tolerate foreign matter (i.e. air systems), leave the first thread exposed and apply the tape sealant as outlined above.

d. When using paste sealant, apply to threads with a brush, using the brush to work the sealant into the threads. Apply

enough sealant to fill in all the threads all the way around.

e. When connecting one stainless steel part to another stainless steel part that will require future disassembly, use a

thread sealant that is designed for stainless steel. This stainless steel thread sealant is also useful when connection

aluminium to aluminium that needs to be disconnected in the future. These two materials gall easily, and if the

correct sealant is not used, it can be next to impossible to disassemble.

f. When connecting parts made of dissimilar metals (i.e. steel and aluminium), standard tape or paste sealant performs

satisfactory.

1

The torque forces recommended bases on a thread friction coefficient µ=0,16 at 70% of the preload force

Loading...

Loading...