8

Mareli Systems

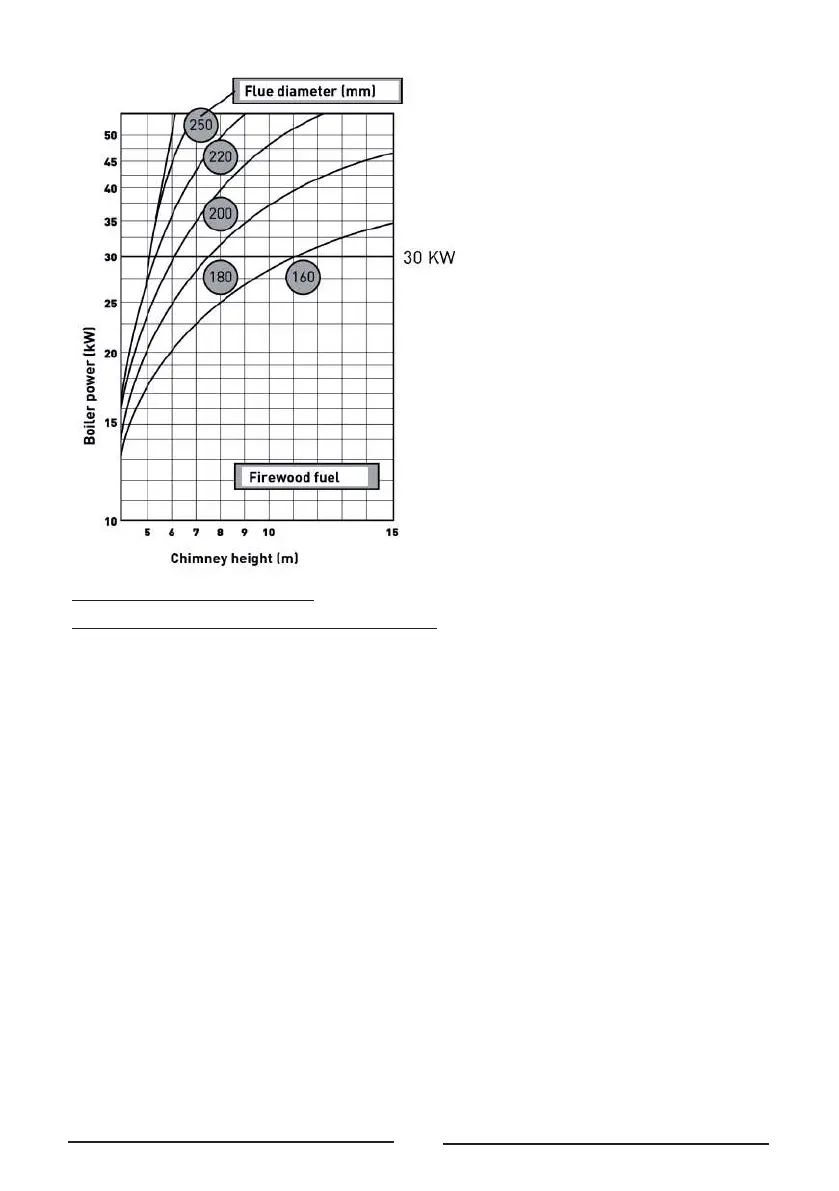

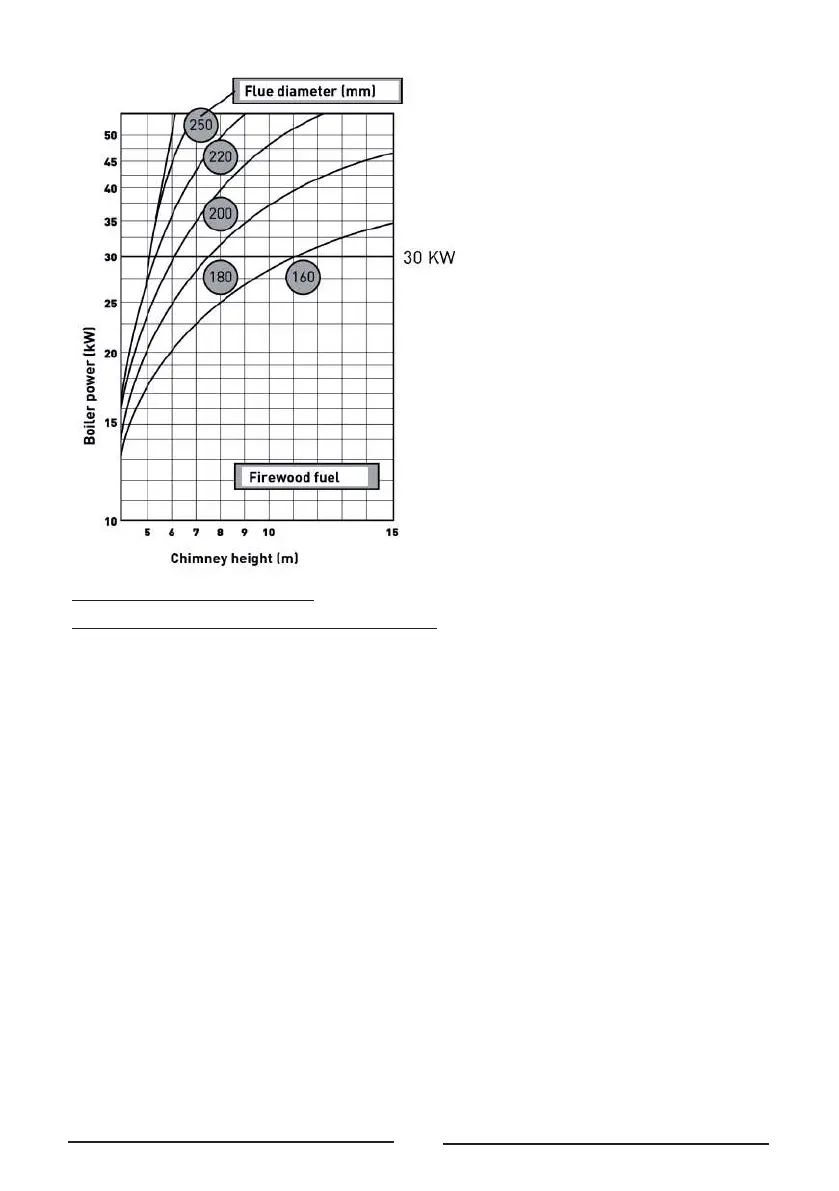

e dimensioning of the chimney is a

very important condition for the opera-

tion of the boiler at optimal parameters.

e chimney must be designed in such a

way as to make the gases escape correctly

and to keep the necessary air in the boiler.

e diagrams below show how to choose

the height of the chimney depending on

its diameter and the power of the boil-

er. Choosing the right insulation for the

chimney is very important and it must be

30-50 mm thick. e correct choice of the

chimney diameter and height are decisive

in the correct operation of the boiler. To

meet the above conditions, consult the

chimney manufacturer’s specialists. e

minimum height of the chimney for solid

fuel-burning boilers is 6 m. e chimney

must be made of stainless steel elements, to

reduce the inuence of condensation.

3. BOILER INSTALLATION

3.1. Connecting the boiler to a heating system

Heat agent temperature without storage system. Regardless of the type of fuel used for heating, the water tem-

perature must not exceed 90°C. In order to prevent the temperature from rising, it is recommended to install

some safety and control accessories.

e safety valve - must always be positioned and mounted close to the boiler in such a way that access is easy.

e safety valve must be calibrated at a pressure of 2.5 bar. e diameter of the valve opening must reach up to

15 mm. e connection to the boiler must be as short as possible. Any joint, welding, bends or other blockage

must be avoided on the connecting pipe. In the case of unavoidable bends, they must have a curvature of r >3D

(D = radius of curvature) and less than ά > 90.

e closed expansion tank must be mounted as close as possible to the boiler. e connection between the

boiler and the vessel must be as short as possible. e installation of the expansion vessel must be done in line

with the connecting pipe to ensure equal pressure distribution. e report must be:

1kW = 1 liter used.

e safety valve and the expansion vessel must be mounted as close as possible to each other, in the following

order: the expansion vessel closest to the boiler, followed by the safety valve.

It is also recommended that a cleaning device, lter Y, be mounted on the return.

In the event of a power cut when the boiler no longer works properly - any increase in pressure will be taken

over by the expansion vessel rst, and at any increase in pressure to a higher value, the safety valve will open

automatically.

Careful! AIR MUST NOT ENTER THE BOILER!

Loading...

Loading...