10

field repair

General

Geareducers can be repaired in the field—however, major repairs

require the use of a fully equipped machine shop. When field repair

or replacement of parts is necessary, the following procedure is

recommended for the disassembly and assembly of the unit. If any

O-ring, oil seal or gasket is to be reused, care should be taken

not to damage it during disassembly. Parts which contain O-rings

or seals should not be jerked or twisted past a shoulder or edge.

These parts are marked with an asterisk (*) in the description

below. O-rings, oil seal and gaskets should be carefully inspected

for damage before being reinstalled. SPX recommends that new

O-rings and oil seal be installed during every major overhaul.

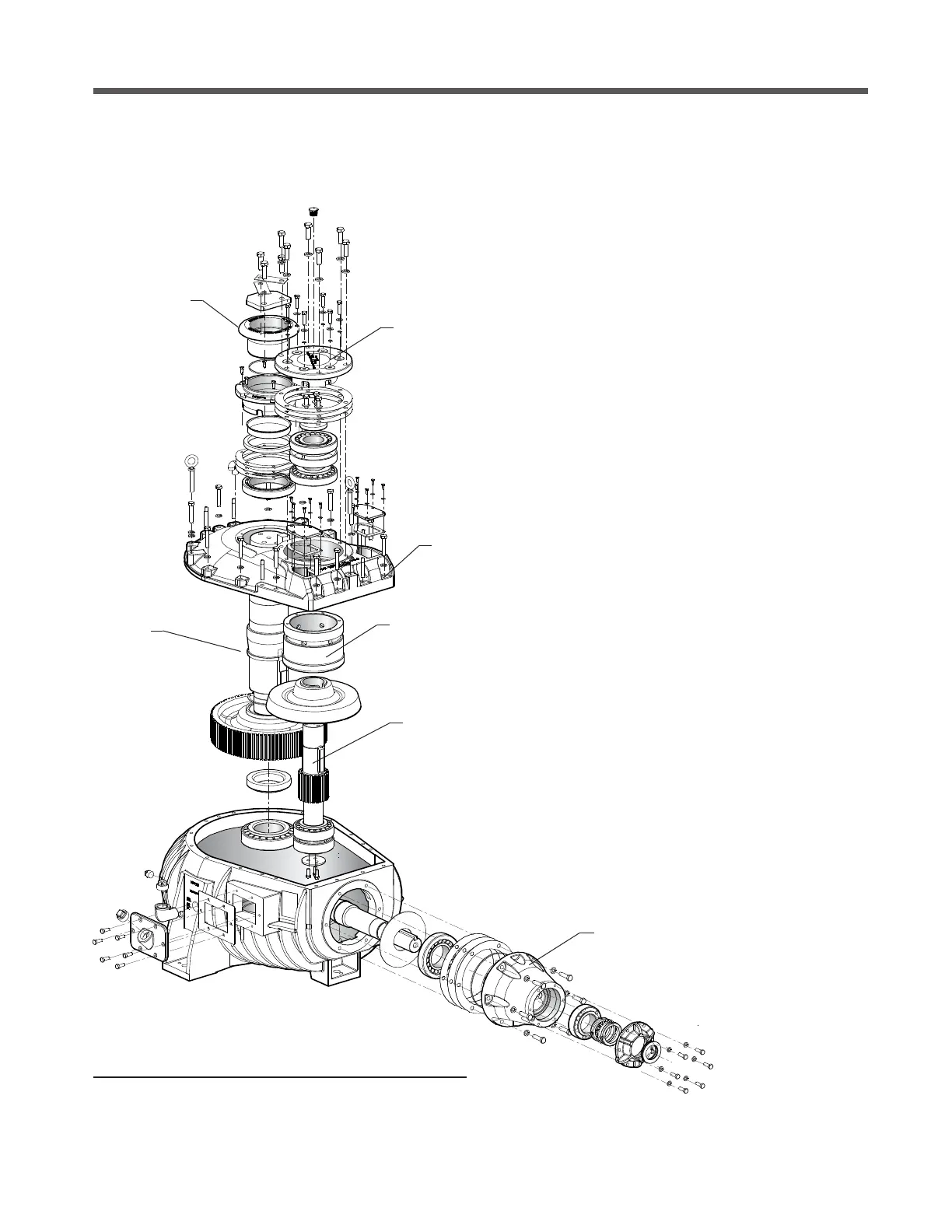

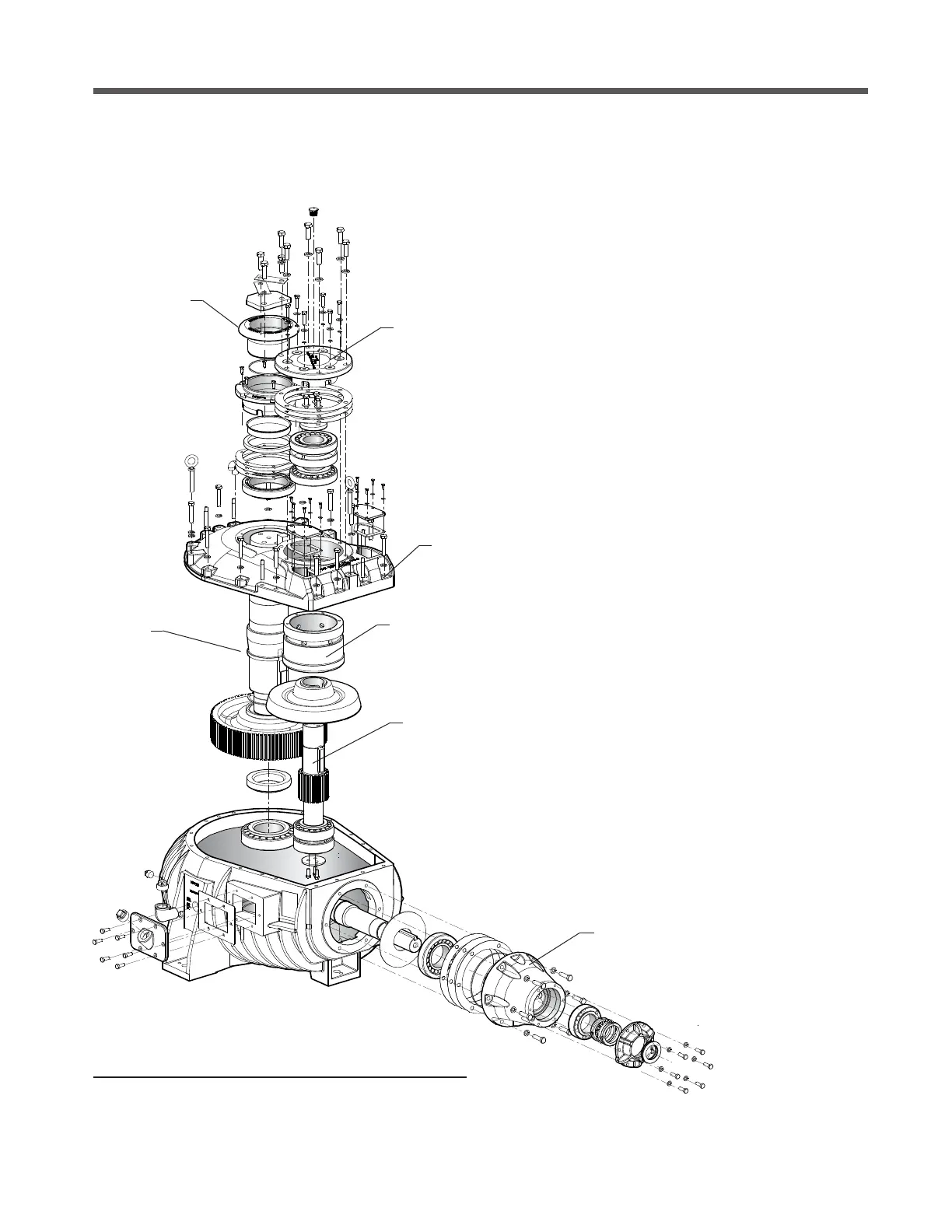

Disassembly of Major Subassemblies

Part numbers and references—refer to Figures 6 and 7.

1. Drain oil.

2. Remove interstage bearing cap.

3. Pull water slinger off fan shaft.*

4. Lift off Geareducer case cover.

5. Pull interstage shaft and fan shaft subassemblies out of

Geareducer case simultaneously.

6. Remove pinion cage subassembly.*

Figure 7 Disassembly of Major Subassemblies

2

3*

4

5

5

5

6*

Loading...

Loading...