14

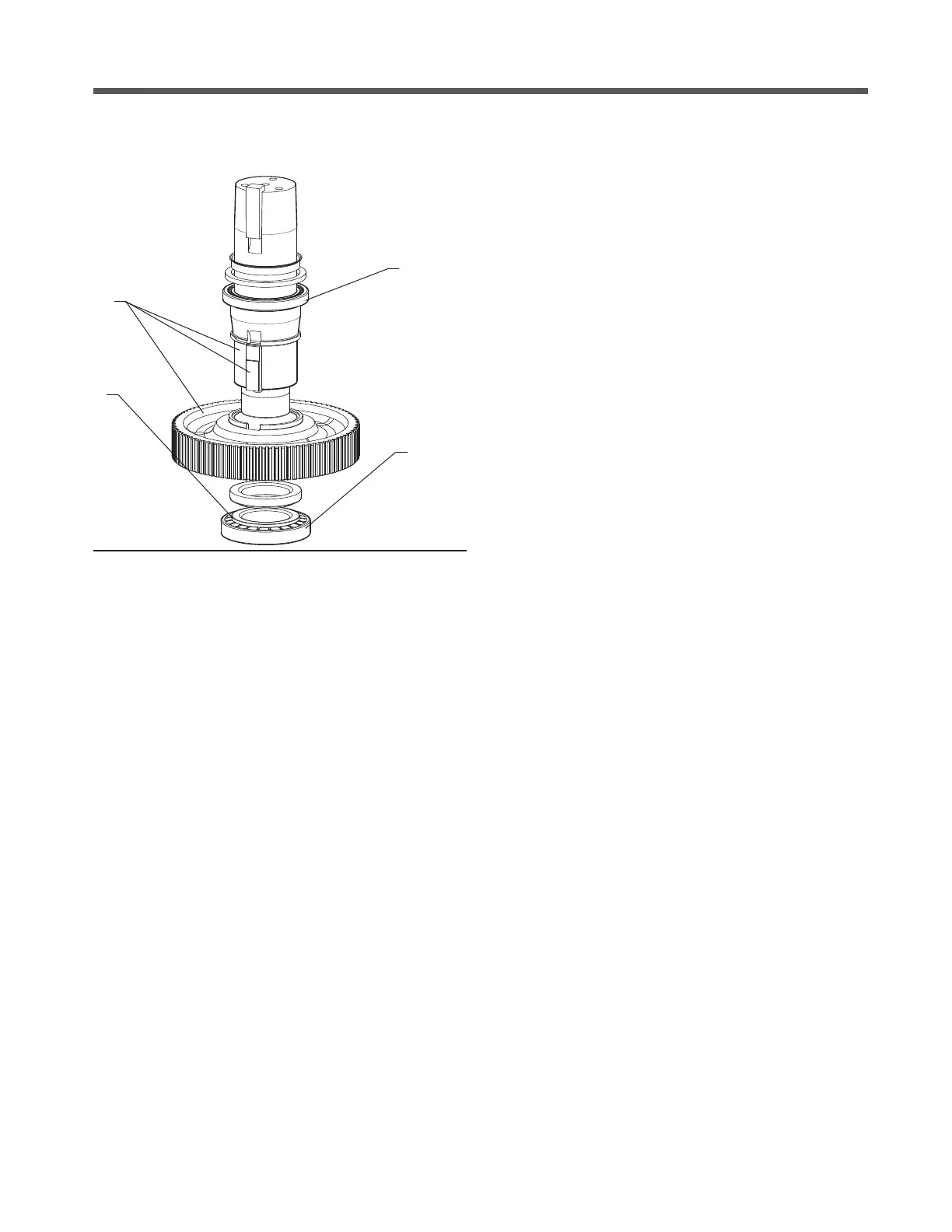

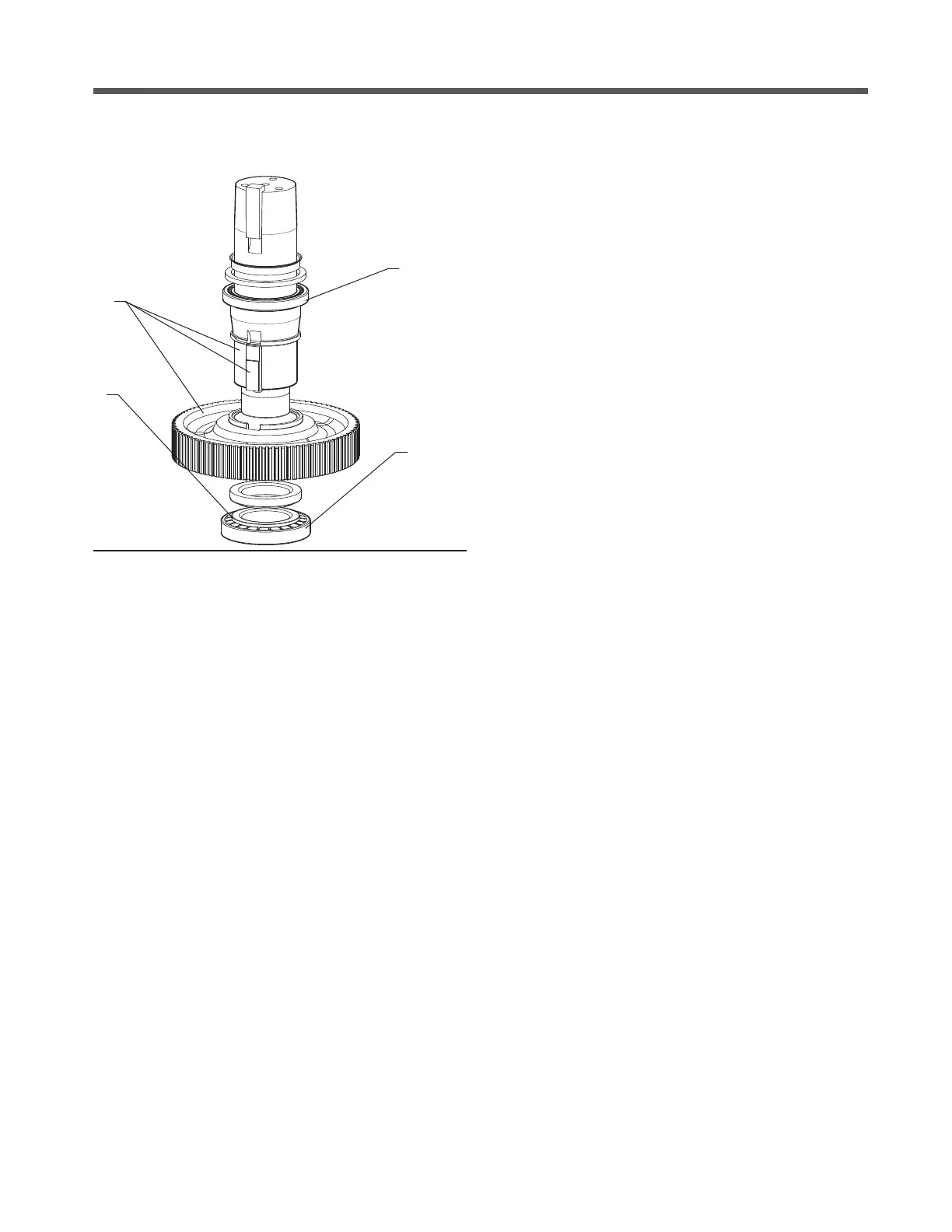

Figure 14 Fan Shaft Assembly

1

2

Fan Shaft Assembly

Part numbers and references—refer to Figures 6 and 14.

1. Install the key spacer ring. Install helical gear key and press

helical gear (201) on fan shaft.

2. Press lower bearing spacer (40) on fan shaft.

3. Press bottom bearing cone (421) onto fan shaft.

4. Press upper bearing cone (422) on fan shaft

5. Install lower fan shaft bearing cup (421) into Geareducer

case (not illustrated).

Final Assembly

Part numbers and references—refer to Figure 15.

1. Install O-ring (702) onto pinion cage subassembly.

2. Bolt pinion cage subassembly to case using proper number

of shims to give indicated pinion setting distance which is

etched on front face of pinion gear. See Figure 11. Tighten

to 75 ft·lb

ƒ

(102 N·m) torque.

3

4

3. Lower fan shaft and interstage shaft subassemblies into case

simultaneously. Engage marked spiral bevel ring gear teeth

with marked spiral bevel pinion tooth. The gear and pinion

are match-marked when lapped and must be assembled the

same way. The ring gear has the end of two teeth marked “X”

and the pinion has one tooth so marked— the gears should

be engaged with the X-marked pinion tooth between those

marked on the ring gear. Match mark location can be checked

through the inspection opening.

4. Apply a coat of Permatex

®

Form-a-Gasket No. 2 to surface of

Geareducer case which mates with case cover. Lower case

cover subassembly onto case, piloting both shaft subassem-

blies into their respective bores.

5. Install dowel pins (20) to align bearing bores. Fasten case cover

to case with cap screws and eye bolts tightening to 75 ft·lb

ƒ

(102 N·m) torque.

6. Position top interstage cap shims and install interstage bear-

ing cap with place bolts tightening to 85-90 ft·lb

ƒ

(116-122

N·m) torque.

7. Install upper fan shaft bearing cup (422) into Geareducer

case cover (not illustrated).

8. Adjust shims to give proper backlash—.007–.009" normal

(.178–.228mm)—between spiral bevel gears. See Gear Set-

ting Procedure, page 15.

9. Fan shaft bearing must be preloaded to .001–.003" (.025–

.076mm) in the following manner:

a. For cases that have the fan shaft lip seal, press the new

lip seal into the labyrinth ring. Install labyrinth ring in case-

cover initially with a quantity of shims between cover and

labyrinth ring to insure that axial bearing end play exists.

Tighten labyrinth ring cap screws to 35 ft·lb

ƒ

(48 N·m)

torque.

b. Mount a dial indicator to measure axial movement of fan

shaft. Support indicator stand on the cover or interstage

cap adjacent to fan shaft and position indicator to read

on machined top surface of fan shaft

c. Rotate the fan shaft slowly in one direction until all down-

ward movement stops. Rotation is necessary to align the

bearing rollers and seat roller ends on cone lip. Record

the dial indicator reading or zero the indicator.

d. Move shaft in the opposite axial direction by attaching to

the shaft with a swivel joint and hoist and lifting on shaft.

Lifting force should be 800 lb (363 kg) to sufficiently

overcome the weight of the fan shaft assembly. Rotate

the shaft slowly in one direction until all axial movement

stops. Record the dial indicator reading.

field repair

Loading...

Loading...