76

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY SUGGESTED

Fails to split logs

Log is improperly positioned.

Refer to ‘Log Splitter Operation’ section for perfect

log loading.

The sizes or hardness of the log exceeds capacity

of the machine.

Reduce the log sizes before splitting it on the log

the splitter.

Wedge cutting edge is blunt

Refer to ‘Sharpening Wedge’ section to sharpen

cutting wedge.

Oil leaks Locate leak(s) and contact the dealer.

Unauthorized adjustment was made on Max.

Pressure Limiting Screw.

Lower max pressure rating was set.

Contact the dealer.

The log pusher moves jerkily,

making unfamiliar noises and

vibrations

Lack of hydraulic oil and excessive air in the

hydraulic system.

Check oil level for possible oil relling.

Contact the dealer.

Oil leaks around log splitter or

from other points.

Air sealed In hydraulic system while operating

Loosen Bleed Screw by 3 - 4 rotations before

operating the log splitter.

Bleed Screw was not tightened before moving

cylinder ram or from the log splitter.

Tighten the Bleed Screw up before moving.

Oil Drain Bolt with Dipstick is not tight. Tighten the Oil Drain Bolt with Dipstick.

Hydraulic Control Valve Assembly and / or seal(s)

worn.

Contact the dealer.

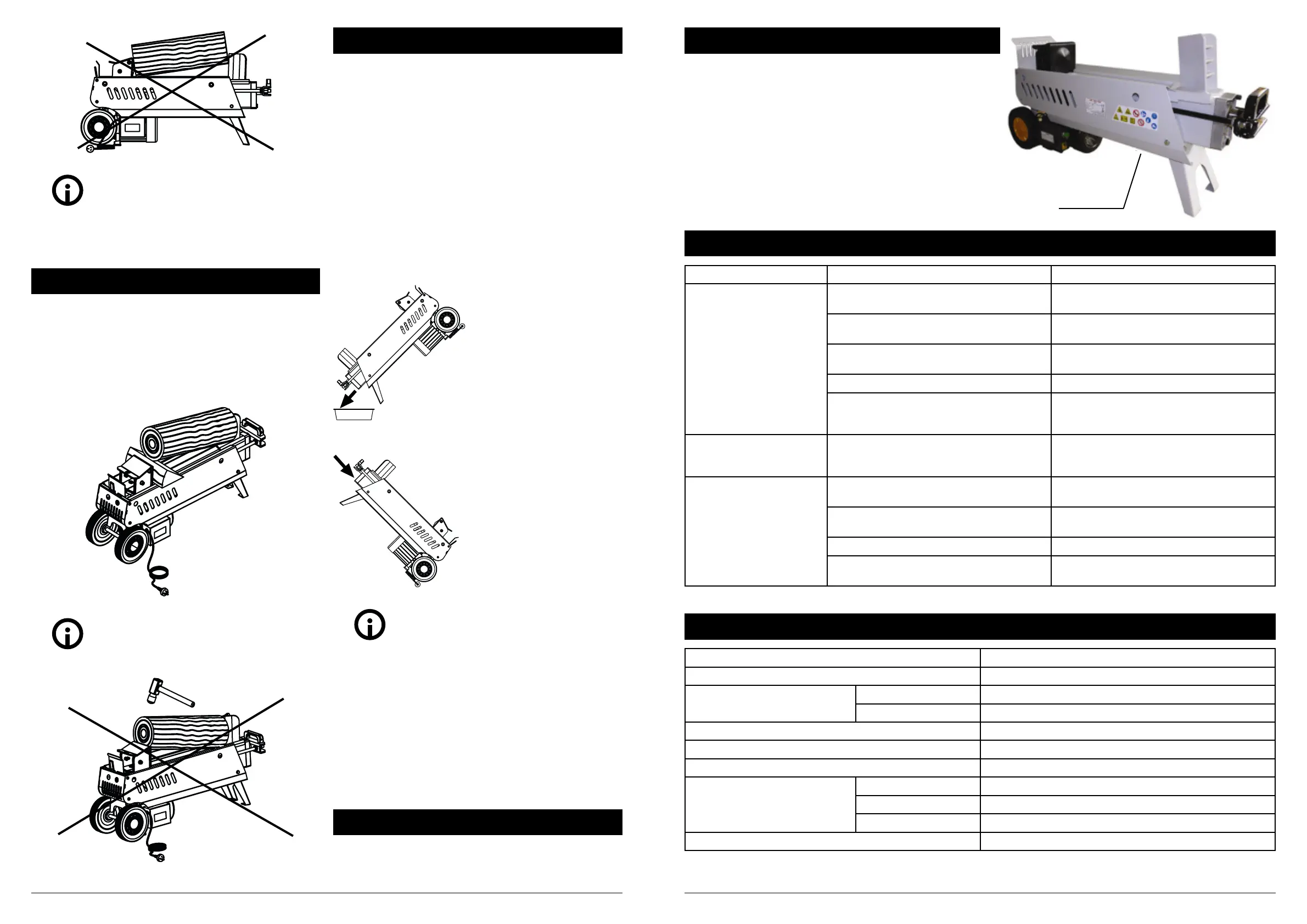

SPECIFICATIONS

Model Number WS7T

Motor - All 2300W S6 40% IP54 230V ~ 50Hz

Log Capacity

Diameter * 5 ~ 320mm

Length 520mm

Splitting Force 7t

Hydraulic Pressure 16Mpa

Hydraulic Oil Capacity 6.5L

Overall Size

Length 1060mm

Width 278mm

Height 522mm

Weight 78kg

* The diameter of the log is indicative— a small log can be dicult to split when it has knobs or a particularly tough bre. On the

other hand, it may not be dicult to split logs with regular bres even if its diameter exceeds the max. Figure indicated above.

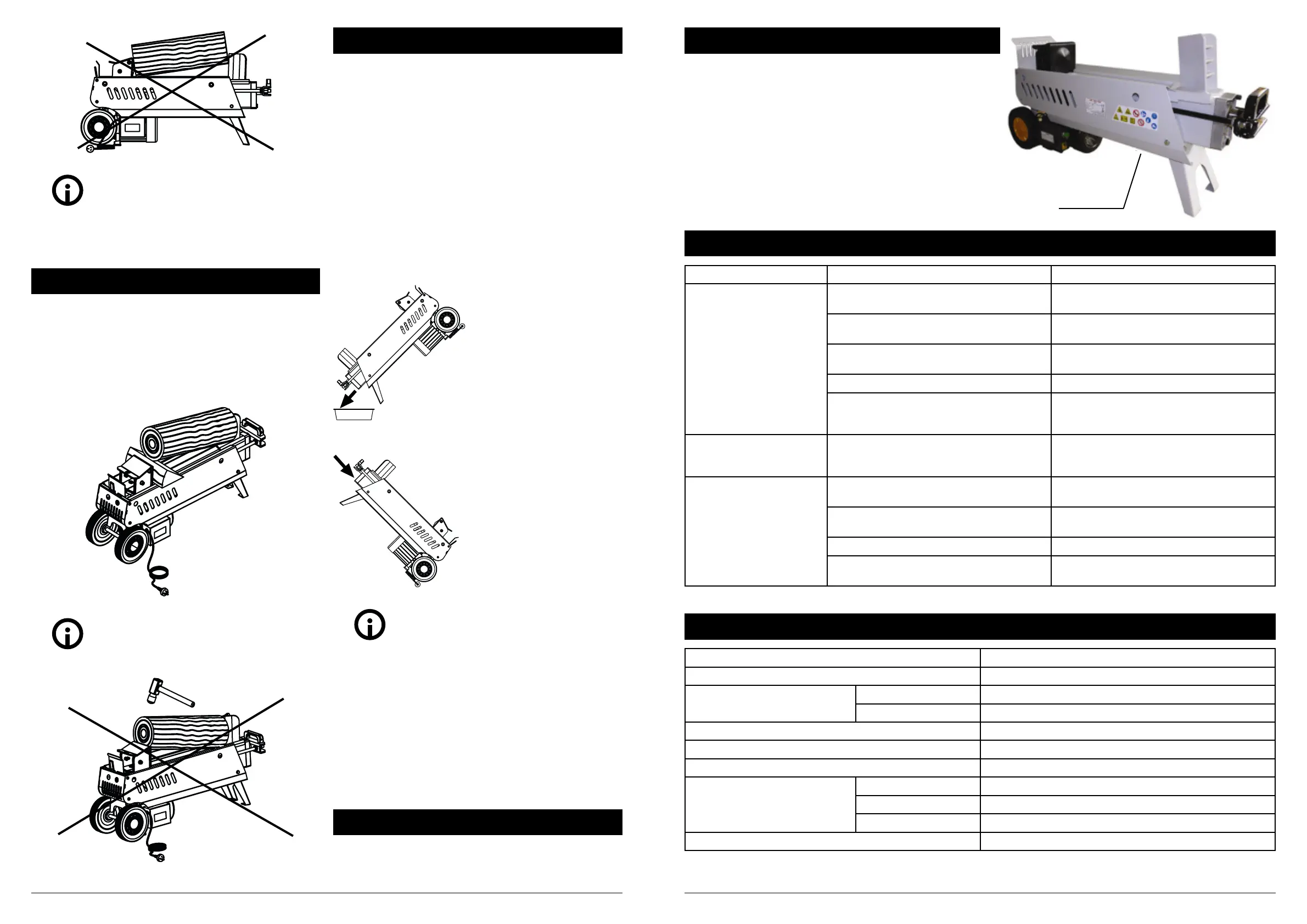

Important!

Break log in the direction of its growing grain. Do

not place log across the log splitter for splitting.

It may be dangerous and may seriously damage

the machine. Do not attempt to split two pieces

of logs at the same time. One of them may y up

and hit you.

FREEING A JAMMED LOG

• Release both controls.

• After the log pusher moves back and completely stops at its

starting position, insert a wedge of wood under the jammed

log.

• Start the log splitter to push the wedge further under the

jammed piece lifting it.

• Repeat above procedure with a sharper slope wedge of wood

until the log becomes completely free.

Important!

Do not try to knock the jammed log o.

Knocking about will damage the machine or may

launch the log and cause accident.

REPLACING HYDRAULIC OIL

Replace the Hydraulic oil in the log splitter after every 400 hours of

use. Take following steps to replace it.

• Make sure all moving parts stops and the log splitter is unplugged.

• Unscrew Oil Drain Bolt with Dipstick to remove it.

• Turn the log splitter on the support leg sside over a 8litre

capacity container to drain the hydraulic oil o.

• Turn the log splitter on the motor side.

• Rell fresh hydraulic oil at the volume as per the hydraulic oil

capacity of a particular model indicated in above specications

table.

• Clean the surface of dipstick on the oil drain bolt and put it

back into the oil tank while keeping the log splitter vertical

• Make sure the level of the relled oil is just between 2 grooves

around the dipstick.

• Clean the oil drain bolt before threading back. Make it’s

tightened to avoid leakage before placing the log splitter

horizontally.

Important!

Periodically check oil level to ensure it is

between 2 grooves around the Dipstick. Upon

Lower oil level, oil relling is required.

Following hydraulic oils or equivalent are

recommend for the log splitter’s hydraulic

transmission system:

Any hydraulic uid sold from a hardware or

automotive supply stores. For example:

SHELL Tellus 22.

MOBIL DTE 11

ARAL Vitam GF 22

BP Energol HLP-HM 22

SHARPENING THE WEDGE

After using the log splitters for some time, sharpen the wedge of

the log splitter using a ne-toothed le and smooth any burrs or

crushed area along the cutting edge.

Serial Number Location

Example: 11 02 1022TP1690 0005

SERIAL NUMBER LOCATION

Loading...

Loading...