26 27

model no. 055-6745-2 | contact us 1-800-689-9928

wood fence can be mounted to your saw. Holes are provided in the saw fence to attach an auxiliary

wood fence (this provides additional depth of cut). This fence should be constructed of straight

auxiliary wood approximately 3/4” (1.9 cm) thick by 3” (7.6 cm) high by 19” (48.3 cm) long. Attach

the wood fence securely and make a full depth cut to make a blade slot. Check for interference

between the wood fence and the lower blade guard. Adjust if necessary.

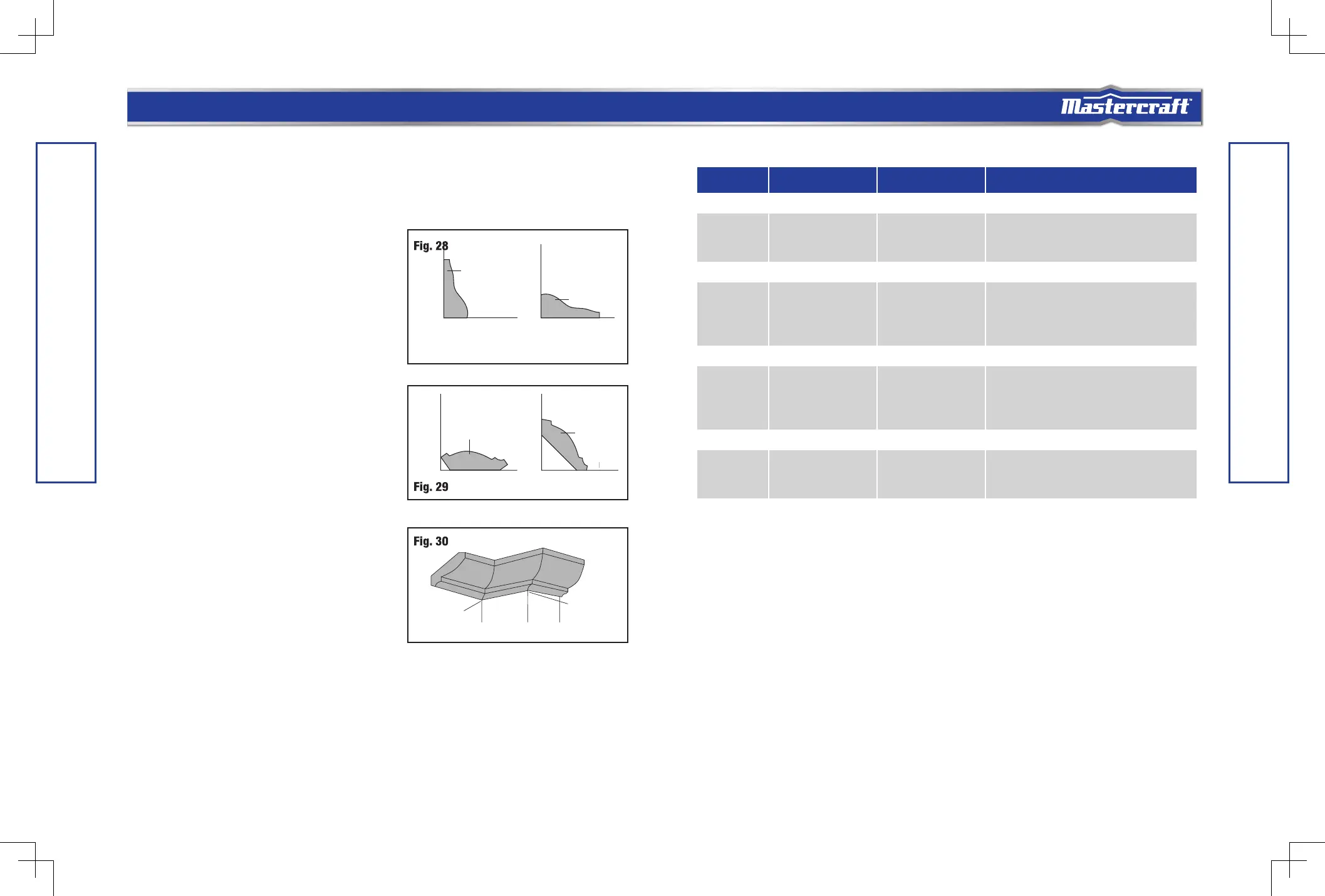

CUTTING BASE MOULDING

Base mouldings and many other mouldings can be cut

on a compound mitre saw. The setup of the saw depends

on moulding characteristics and applications, as shown.

Perform practice cuts on scrap material to achieve best

results:

• Always make sure mouldings rest firmly against

the fence and table. Use hold-down or C-clamps,

whenever possible, and place tape on the area being

clamped to avoid marks.

• Reduce splintering by taping the cut area prior to

making cut. Mark cut line directly on the tape.

• Splintering typically happens due to wrong blade

application and thinness of the material.

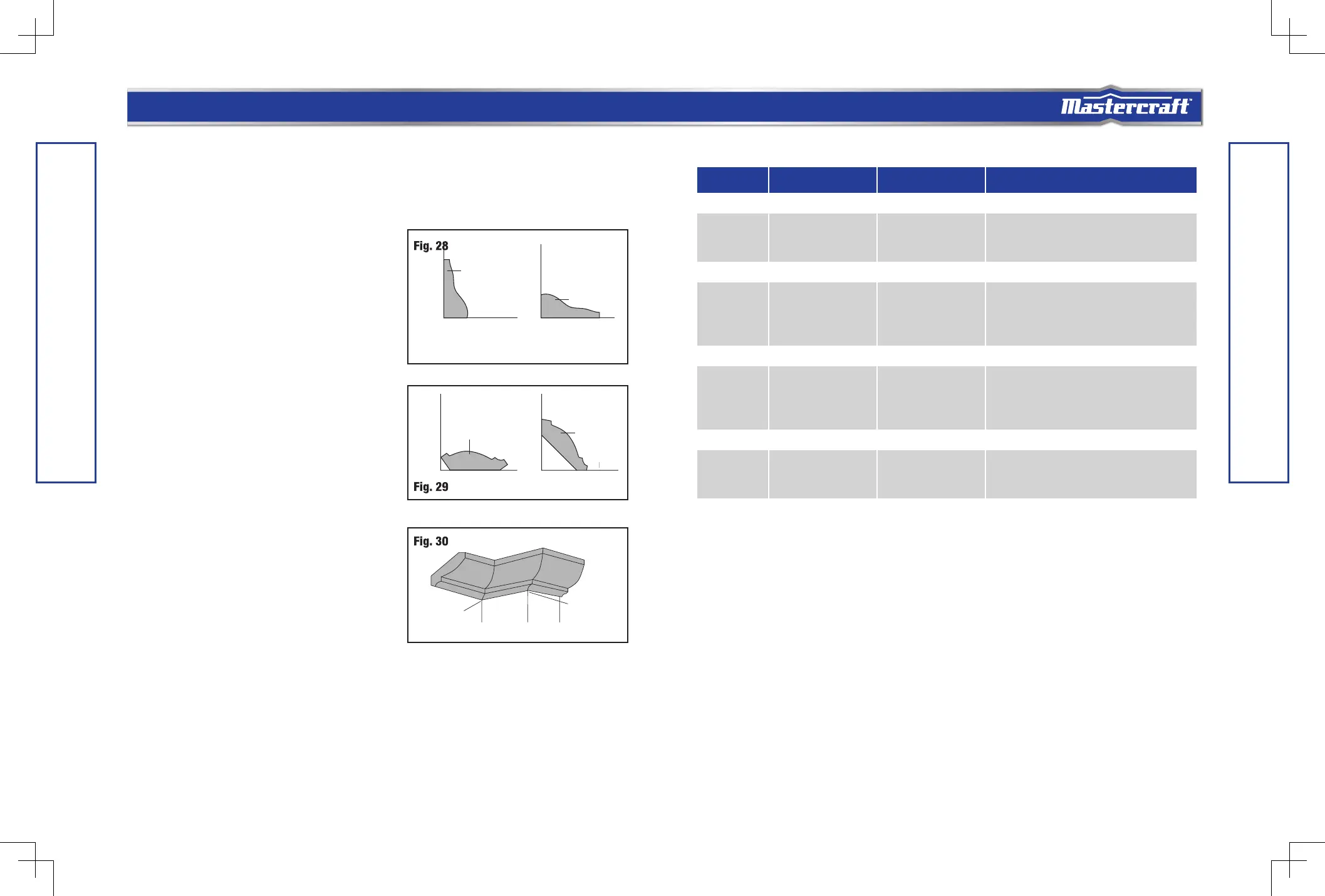

CUTTING CROWN MOULDING (Fig. 29, 30)

Your compound mitre saw is suited for the difcult task of

cutting crown moulding. To t properly, crown moulding

must be compound-mitreed with extreme accuracy. The

two surfaces on a piece of crown moulding that t at

against the ceiling and wall are at angles that, when added

together, equal exactly 90°.

Most crown moulding has a top rear angle (the section that

ts at against the ceiling) of 52° and a bottom rear angle

(the section that ts at against the wall) of 38°.

In order to accurately cut crown moulding for a 90° inside

or outside corner, lay the moulding with its broad back surface at on the saw table. When setting

the bevel and mitre angles for compound mitres, remember the settings are interdependent;

changing one changes the other, as well.

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Bevel/Mitre Settings (when the angle between the walls equals 90°)

Inside corner - Left side

IL 33.9° 31.6° Right 1. Position top of moulding against fence.

2. Mitre table set at RIGHT 31.6°.

3. LEFT side is finished piece.

Inside corner - Right side

IR 33.9° 31.6° Left 1. Position bottom of moulding against

fence.

2. Mitre table set at LEFT 31.6°.

3. LEFT side is finished piece.

Outside corner - Left side

OL 33.9° 31.6° Left 1. Position bottom of moulding against

fence.

2. Mitre table set at LEFT 31.6°.

3. RIGHT side is finished piece.

Outside corner - Right side

OR 33.9° 31.6° Right 1. Position top of moulding against fence.

2. Mitre table set at RIGHT 31.6°.

3. RIGHT side is finished piece.

IL

IR

OL

OR

Inside

Corner

Outside

Corner

Fence

Mitre saw table

Workpiece

Fence

Mitre saw table

Workpiece

Fence

Mitre saw table

Workpiece

Mitre at 45°

bevel at 0°

Fence

Mitre saw table

Mitre at 0°

bevel at 45°

Workpiece

Loading...

Loading...