26 Fr

Soudeuse à dévidage de fil-électrode

1 Assemblage du chalumeau et

tuyau (MIG) WC403660AV 1

2 Pointe de contact - 0,035 po (0,9 mm) WT501400AV 1

Pointe de contact optionnelle -

0,024 po (0,6 mm) paquet de 4 WT501200AJ †

Pointe de contact optionnelle -

0,030 po (0,8 mm) paquet de 4 WT501300AJ †

Pointe de contact optionnelle -

0,035 po (0,9 mm) paquet de 4 WT501400AJ †

3 Buse WT502100AV 1

4 Rouleau entraîneur WC500805AV 1

5 Assemblage du tablier d'entraînement WC500800AJ 1

6 Broche et grille WC707018AV 1

7 Dispositif de retenue de bobine WC707024AV 1

8 Ressort de retenue de bobine WC707026AV 1

9 Anneau de retenue de bobine WC707023AV 1

10 Fil de soudure fourré - 0,030 po (0,8 mm)

2 lb (0,9 kg) Rouleau (E71T-GS) WE200001AV †

Fil de soudure fourré - 0,030 po (0,8 mm)

10 lb (4,5 kg) Rouleau (E71T-GS) WE201000AV †

Fil de soudure fourré - 0,035 po (0,9 mm)

2 lb (0,9 kg) Rouleau (E71T-GS) WE200501AV †

Fil de soudure fourré - 0,035 po (0,9 mm)

10 lb (4,5 kg) Rouleau (E71T-GS) WE201500AV †

Fil de soudure MIG - 0,024 po (0,6 mm)

2 lb (0,9 kg) Rouleau (ER70S6) WE300001AV †

No de

réf. Description No de pièce Qté.

Fil de soudure MIG - 0,024 po (0,6 mm)

11 lb (5 kg) Rouleau (ER70S6) WE301500AV †

Fil de soudure MIG - 0,030 po (0,8 mm)

2 lb (0,9 kg) Rouleau (ER70S6) WE300501AV †

Fil de soudure MIG - 0,030 po (0,8 mm)

11 lb (5 kg) Rouleau (ER70S6) WE302000AV †

Fil de soudure MIG - 0,035 po (0,9 mm)

2 lb (0,9 kg) Rouleau (ER70S6) WE301001AV †

Fil de soudure MIG - 0,035 po (0,9 mm)

11 lb (5 kg) Rouleau (ER70S6) WE302500AV †

Fil de soudure MIG - 0,030 po (0,8 mm)

1 lb (0,45 kg) Aluminium (ER5356) WE303001AV †

11 Dispositif de retenue de la bouteille

avec 4 vis WC302600AJ 1

12 Raccord de tuyau barbelé (externe) WC403900AV 1

Raccord rapide (interne) WC403901AV 1

13 Tuyau de gaz - 22 po (55,9 cm) WC403902AV 1

14 Collier de serrage de tuyau WC403903AV 2

15 Régulateur WC802500AV 1

16 Masque de soudage à main

(lentille non incluse) WC801700AV 1

17 Lentille ombragée

(pour masque de soudage à main) WC801100AV 1

18 Marteau/brosse de piquage WC803400AV 1

19 Décalque de sécurité DK688509AV 1

20 Trousse de barre-omnibus de polarité WC403128AV 1

Pas indiquée

† Accessoire optionnel

No de

réf. Description No de pièce Qté

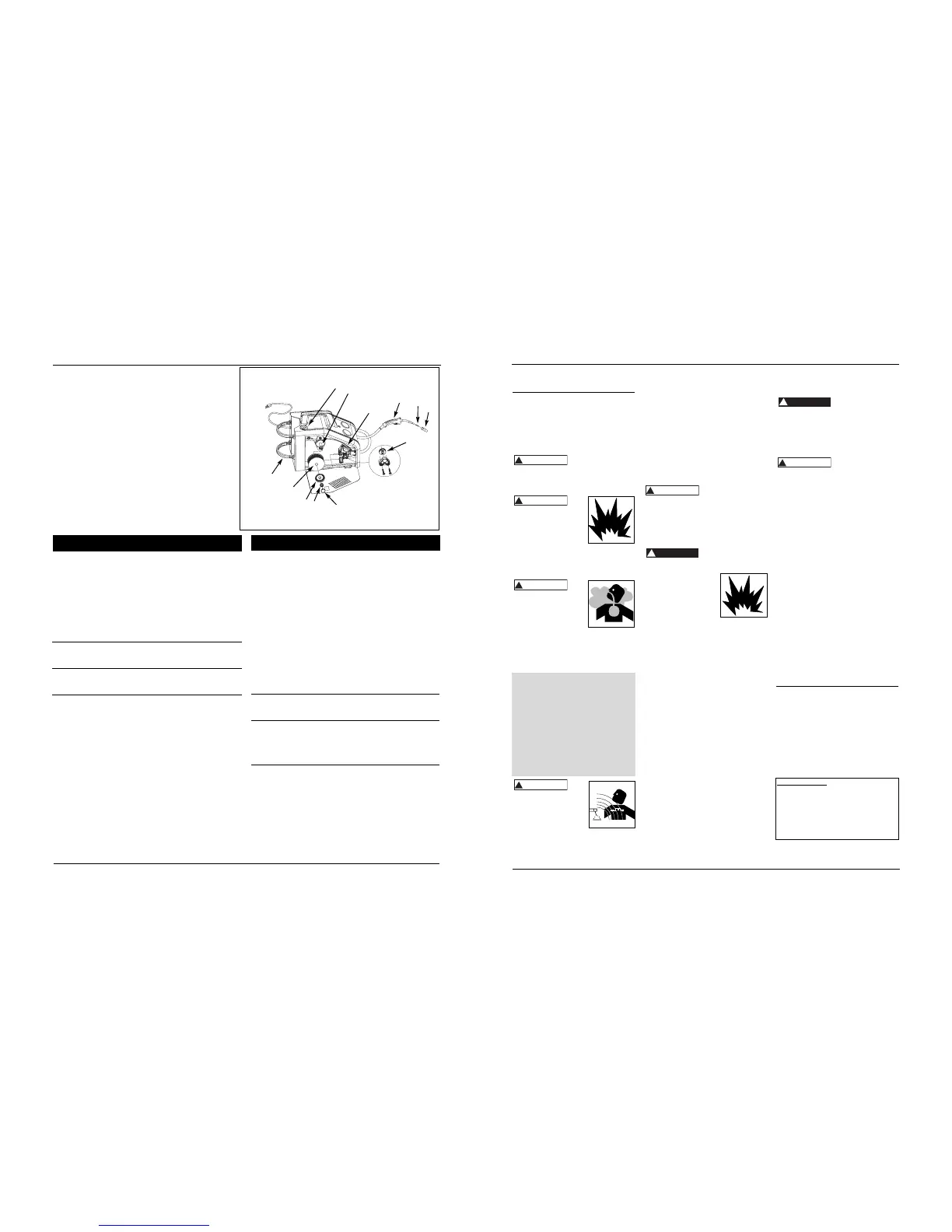

3

4

1

8

9

2

11

10

7

12

6

5

Figure 15 - Pièces de rechange

Pour pièces de rechange ou

assistance technique, appeler

1 866 220-2097

S’il vous plaît fournir l’information suivante :

- Numéro de modèle

- Numéro de série (si applicable)

- Numéro et description de la pièce

Liste de pièces de rechange

General Safety

(Continued)

Do not operate electric arc welder in

areas where flammable or explosive

vapours may be present.

Take precautions to ensure flying

sparks and heat do not cause flames

in hidden areas, cracks, etc.

Fire hazard! Do not

weld on containers

or pipes that contain or have contained

flammable materials or gaseous or liquid

combustibles.

Arc welding closed

cylinders or containers

such as tanks or drums

can cause explosion if

not properly vented!

Verify that any cylinder or container to

be welded has an adequate ventilation

hole, so that expanding gases can be

released.

Do not breathe fumes

produced by arc

welding operation.

These fumes are

dangerous. If welding

area cannot be adequately ventilated,

be sure to use an air-supplied

respirator.

Keep head and face out of welding

fumes.

Extremely toxic fumes are created

when galvanized or cadmium-plated

metals or metals which contain zinc,

mercury or beryllium are heated.

Complete the following precautions

before performing electric arc

welding operations on these metals:

a. Remove coating from base metal.

b. Make sure welding area is well

ventilated.

c. Use an air-supplied respirator.

The electromagnetic field

generated during arc

welding may interfere

with the operation of

various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician prior

equipment, and CGA publication P-1

listed in Safety Standards.

Never use

flammable gasses

with MIG welders. Only inert or non-

flammable gasses such as carbon

dioxide, argon, helium or mixtures of

one or more of these gasses are

suitable for MIG welding.

Never lift cylinders

off the ground by

their valves or caps or with chains or

slings.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society.

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed Gas

Association.

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association.

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association.

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute.

Installation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and the life of the arc welder.

For best results use welder in a clean

and dry environment. Dust and dirt

in the welder retains moisture and

increases the wear of moving parts.

3

to performing any electric arc welding

operations.

Route wire gun and work cables

together and secure with tape when

possible.

Never wrap arc welder cables around

the body.

Always position wire gun and work

leads on the same side of the body.

Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

welding area is

secure and free of hazards (sparks,

flames, glowing metal or slag) prior to

leaving. Be sure equipment is turned off

and excess wire is cut off. Be sure cables

are loosely coiled and out of the way. Be

sure all metal and slag has cooled.

Cylinders can explode if damaged.

Shielding gas cylinders

contain gas under high

pressure. If damaged, a

cylinder can explode.

Since gas cylinders are

normally part of the

welding process, be

sure to treat them carefully.

Protect compressed gas cylinders

from excessive heat, mechanical

shocks and arcs.

Install and secure cylinders in an

upright position by chaining them

to stationary support or equipment

cylinder rack to prevent falling or

tipping.

Keep cylinders away from any

welding or other electrical circuits.

Never allow a welding electrode to

touch any cylinder.

Use only correct shielding gas

cylinders, regulators, hoses and

fittings designed for the specific

application; maintain all parts

properly.

Turn face away from valve outlet

when opening cylinder valve.

Keep protective cap in place over

valve except when cylinder is in use

or connected for use.

Read and follow instructions on

compressed gas cylinders, associated

Loading...

Loading...