OPERATING THE BENCH GRINDER

6. NOTE: The left hand arbor hex nut (E) is

left hand threaded and is loosened by rotating

it clockwise. The right hand arbor hex nut is

right hand threaded and is loosened by

rotating it counter-clockwise.

7. Remove the Outer Wheel Flange (H) and

then the abrasive wheel (I) from the arbor

shaft.

8. The new abrasive

wheel to be put onto the grinder must have

a higher R.P.M. rating than the grinder (3450

R.P.M.). The new abrasive wheel must have

the correct outer wheel diameter and bore

diameter as original wheels. The label on the

side of the abrasive wheel must stay on. DO

NOT remove this label.

9. Replace the abrasive wheel, outer wheel

ange and arbor hex nut. NOTE: The left

hand arbor hex nut is left hand threaded and

is tightened by rotating it counter-clockwise.

The right hand arbor hex nut is right hand

threaded and is tightened by rotating it

clockwise.

DO NOT OVER

TIGHTEN the arbor hex nut as this may

damage the abrasive wheel and cause

serious injury to the operator.

Turn the power switch “OFF” and unplug the

power cord from its power source prior to any

maintenance.

LUBRICATION

The Bench Grinder has sealed lubricated

bearings in the motor housing that do not

require any additional lubrication from the

operator.

CLEANING

With the Bench Grinder unplugged, rotate the

abrasive wheels slowly and inspect for any

damage or trapped shavings.

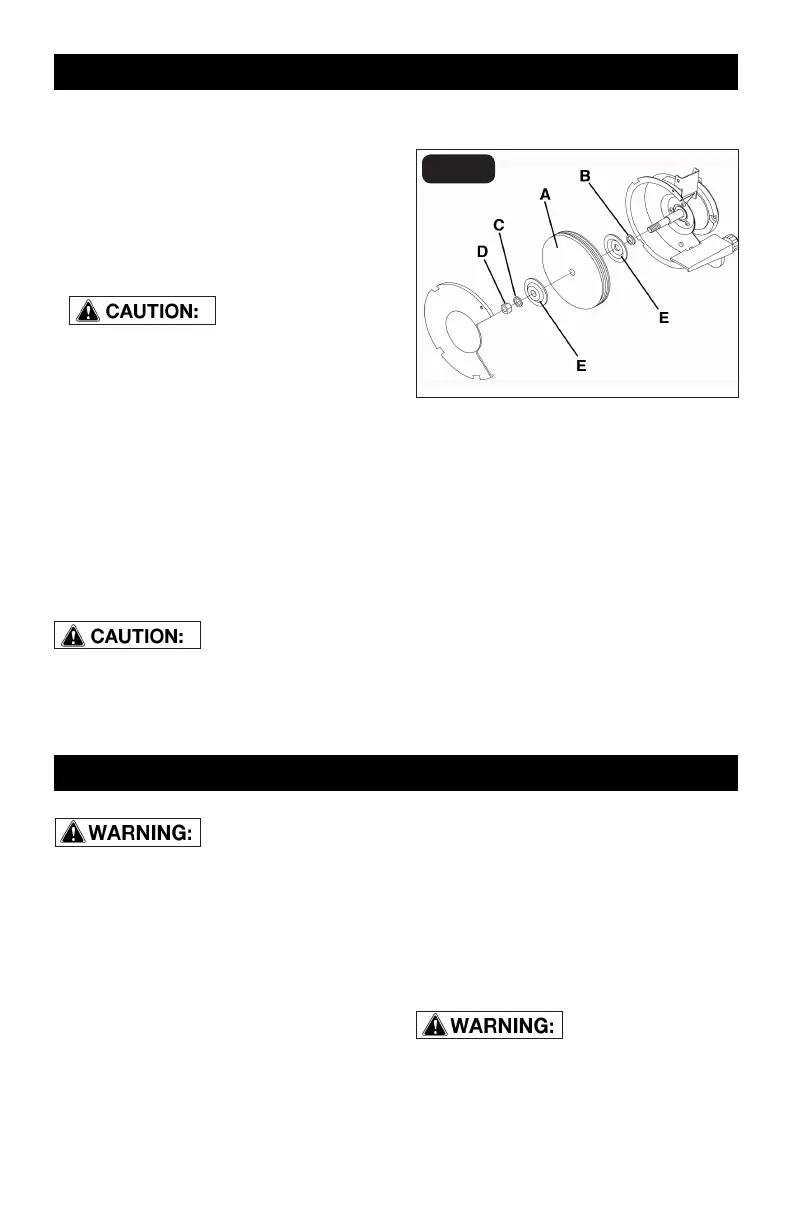

WIRE WHEEL or BUFFING WHEEL (Fig. L)

A wire wheel or bung wheel (A) can be used

with your grinder. Depending on the thickness

of the wheel, you will need to add one or more

spacers to allow the arbor hex nut to tighten

correctly. These spacers are identical to each

other. Figure L shows the correct placement

of the spacers (B) and (C).

Note: One spacer (B) should always go onto

the arbor shaft rst. The second spacer (C),

if needed, will go on next to the arbor hext

nut (D) as shown. Always use the wheel

anges (E) that came with the grinder for both

wire wheel and bung wheels. See section

CHANGING THE GRINDING WHEEL for

correct procedure of changing wheels.

CAUTION: REPLACE the abrasive wheels

if there is any damage at all. FAILURE to

replace a damaged wheel can cause serious

injury to the operator.

CAUTION: DO NOT USE FLAMMABLE

MATERIALS to clean the Bench Grinder. A

clean dry rag or brush is all that is needed to

remove dust and debris buildup.

Repairs to the Bench Grinder should be

performed by trained personnel only.

Unauthorized repairs or replacement with

non-factory parts could cause serious injury

to the operator and damage to the Bench

Grinder.

FIG. L

MAINTENANCE OF THE BENCH GRINDER

Page 15

Loading...

Loading...