INSTALLATION

EN/ Whisper 6/8/12/16 Ultra for mobile applications / May 2009 / Copyright © 2009 Mastervolt 21

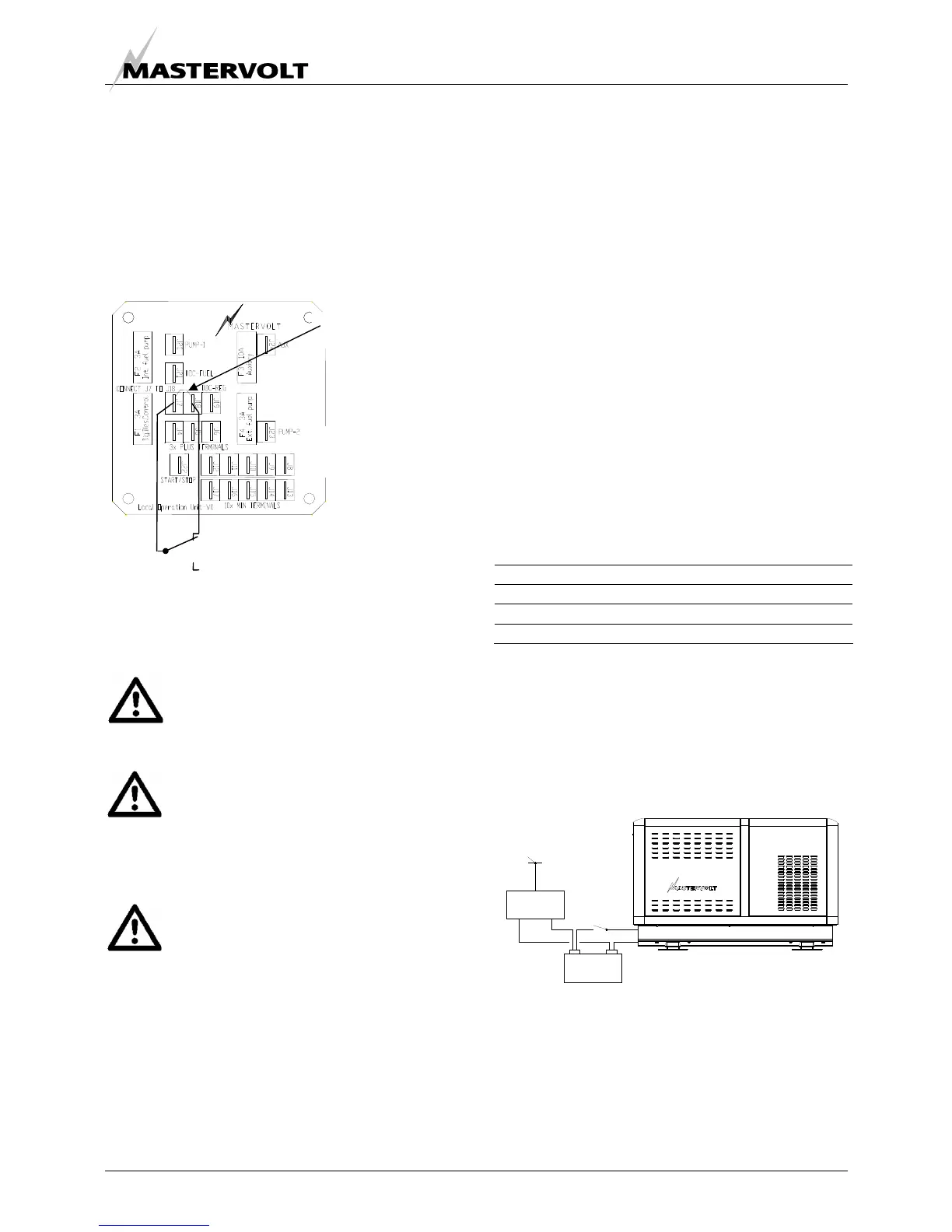

Connection for emergency stop / fire alarm switch

To connect an emergency stop button or to stop the

generator automatically in case of a fire alarm, you can

use the bypass connection between fastons J7 and J18 on

the backside of the local control panel. See fig. 30. To do

so, remove this bypass connection and then replace it by

an emergency switch or a potential free fire alarm switch

with normally closed contacts

Fig. 30: Connection for emergency stop / fire alarm switch

Automatic starting and stopping

Mastervolt cannot be held responsible for

damage caused by the unattended running

generator using the auto-start/stop mode or

interval mode

Using the auto-start/stop (interval) mode the

generator can start unexpectedly. When

working on the electrical system, the 3 Amp

fuse must be removed from the control panel

and the battery plus cable must be removed

from the battery.

In the delivery are warning stickers to stick on

several parts of the electric installation

(transfer switch, distribution box, etc.) to warn

for automatic start)

The Mastervolt Digital Diesel Control system offers several

options for automatic starting and stopping.

Access to this menu and other menus could be blocked.

For de-blocking and setting up this options refer to the

APPENDIX of the DDC user’s manual.

One of these options is to monitor a second battery (not

being the starter battery) to start the generator

automatically when the voltage of this battery drops below

a certain setting.

Other names for this second battery are “auxiliary battery”,

“service battery”, ”users battery” or “consumers battery”.

We will refer to this battery as “the second battery”(BAT2).

In some menus the starter battery could be indicated as

“the first battery” (BAT1).

A sense wire to monitor the second battery should be

connected (attention polarity!) to the connector on the

back of the remote panel. Refer to fig. 29. The sense wires

must be connected directly on the second battery before a

main switch and be protected by a 3 Amps fuse.

(Monitoring the generator starter battery does not require

an extra sense connection)

Settings

When one want to apply other settings than the factory

settings refer to the DDC users manual, especially to the

APPENDIX.

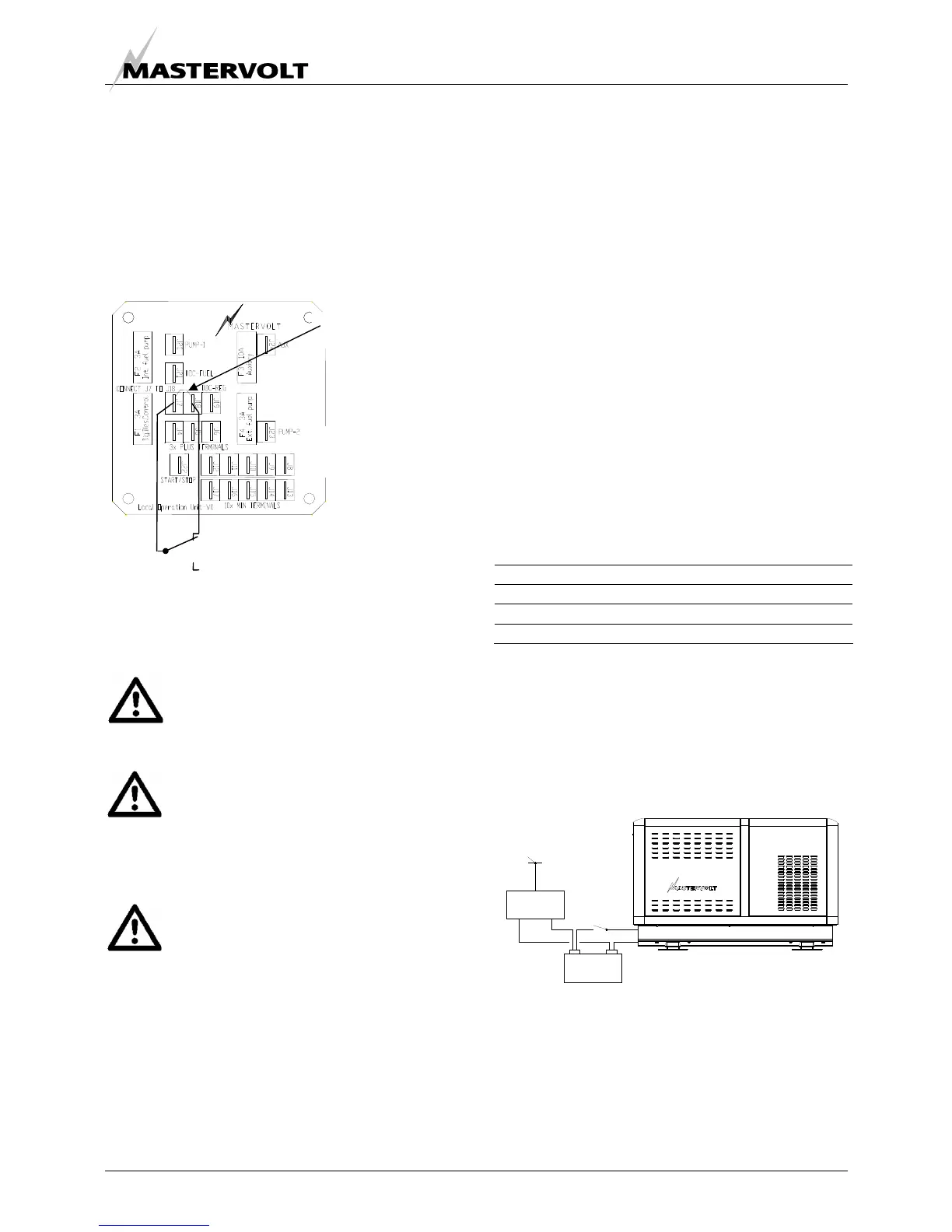

2 STARTER BATTERY

For starting, the Whisper requires a 12V starter battery

with the following capacity:

Model Minimum capacity

Whisper 6 Ultra 60Ah

Whisper 8 Ultra and 12 Ultra 70Ah

Whisper 16 Ultra 120Ah

The generating set can be connected with the main engine

battery or have its own battery.

We strongly recommend the use of a separate battery for

the generating set and to keep the wiring system for the

vehicle engine and the domestic DC supply system

completely separate and individually connected to

separate batteries.

230VAC

IVO 12/10

A

B

12V

+-

Fig. 31 Starter battery

However, the negative of all the batteries on the vehicle

should be interconnected to avoid difference in the voltage

level of the earth on different places causing trouble to

electronic devices which might be in the system.

The above recommendation is not valid for vehicles having

the starter battery of the vehicle engine or other auxiliary

Remove bypass

between J7 - J18

Normal operation

Alarm / emergency

local control panel

(rear view)

Loading...

Loading...