Page 14 of 20 1910308-12

you will be welding. It should be equal to or

greater than the thickness of the actual

work piece, and free of oil, paint, rust, etc.

7.2 Select a heat setting.

7.3 Hold the torch in one hand. Hold the

wire just off the work piece. (See

HOLDING THE TORCH section if you are

uncertain of the angle at which you will be

welding.)

7.4 Set the wire feed speed based on the

thickness of material and the set-up chart

on the back side of the wire feeder door.

7.5 Lower your welding helmet. Pull the

trigger on the torch and let the wire feed

into the work piece to start an arc. Then

begin to drag the torch toward you.

7.6 LISTEN! If the arc is sputtering,

increase the wire speed slightly and try

again. Continue increasing the wire speed

adjustment until you achieve a smooth

buzzing sound. If the wire seems to

"pound" into the work piece, decrease wire

speed slightly and try again. Use the wire

speed control to slightly increase or

decrease the heat and penetration for a

given voltage setting by increasing or

decreasing the wire speed slightly. Repeat

this tune-in procedure if you select a new

voltage setting, a different wire diameter,

or a different roll of wire.

8. WELDING TECHNIQUES

EXPOSURE TO A WELDING ARC IS

EXTREMELY HARMFUL TO THE EYES AND

SKIN! Prolonged exposure to the welding

arc can cause blindness and burns. Never

strike an arc or begin welding until you are

adequately protected. Wear flame-proof

welding gloves, a heavy long-sleeved shirt,

trousers without cuffs, high topped shoes,

and an ANSI approved welding helmet.

ELECTRIC SHOCK CAN CAUSE INJURY OR

DEATH! To prevent ELECTRIC SHOCK, do

not perform any welding while standing,

kneeling, or lying directly on the grounded

workpiece.

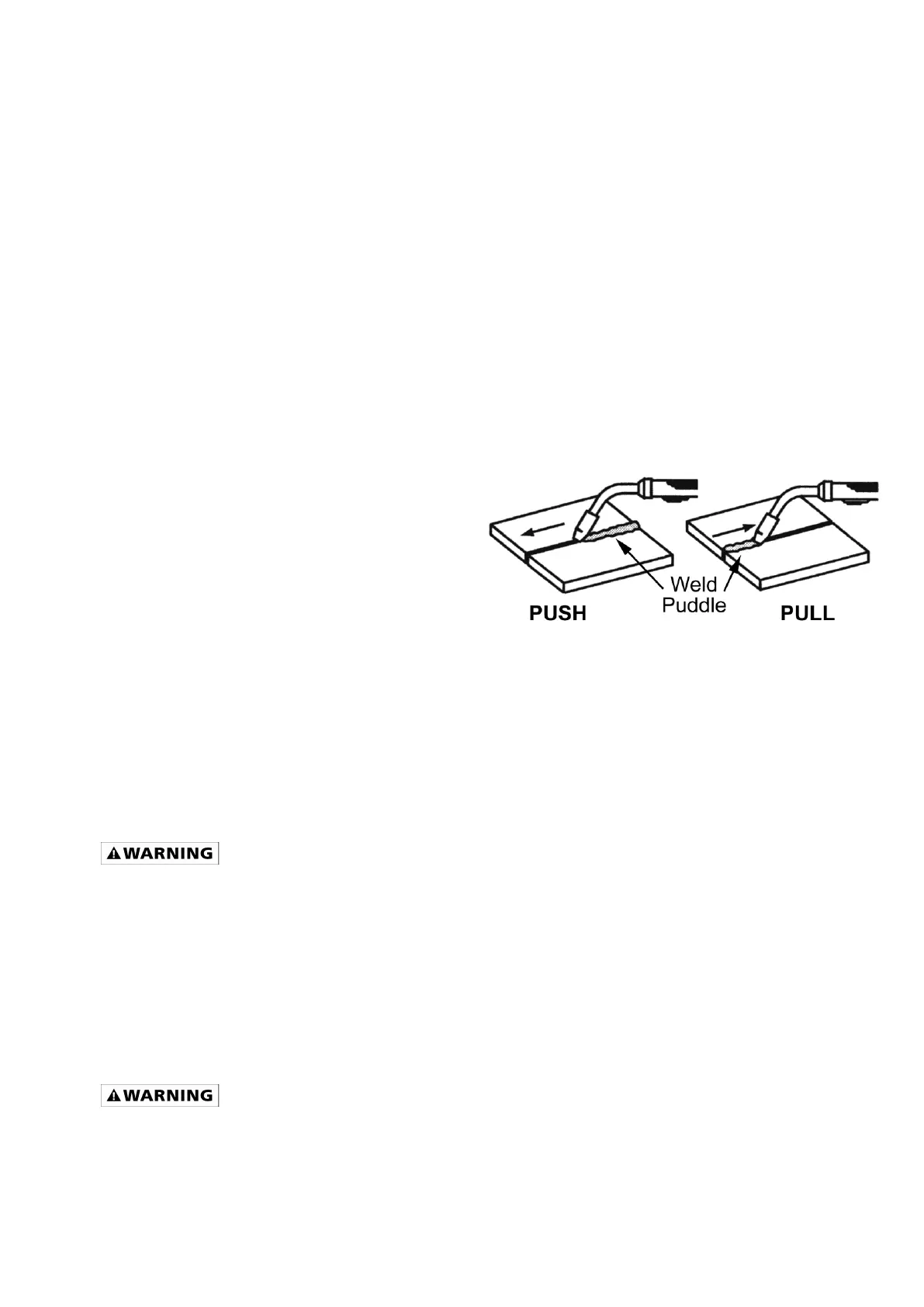

8.1 Moving the torch

Torch travel refers to the movement of the

torch along the weld joint and is broken

into two elements: Direction and Speed. A

solid weld bead requires that the welding

torch be moved steadily and at the right

speed along the weld joint. Moving the

torch too fast, too slow, or erratically will

prevent proper fusion or create a lumpy,

uneven bead. Travel direction is the

direction the torch is moved along the weld

joint in relation to the weld puddle. The

torch is either PUSHED into the weld

puddle or PULLED away from the weld

puddle.

For most welding jobs you will pull the

torch along the weld joint to take

advantage of the greater weld puddle

visibility. Travel speed is the rate at which

the torch is being pushed or pulled along

the weld joint. For a fixed heat setting, the

faster the travel speed, the lower the

penetration and the lower and narrower

the finished weld bead, likewise, the

slower the travel speed, the deeper the

penetration and the higher and wider the

finished weld bead. As a good rule of

thumb, the thickness of a cross-section of

the weld bead should be approximately the

same thickness as the thinnest material

you are welding.

8.2 Types of welding beads

As you become more familiar with your

new welder and better at laying some

simple weld beads, you can begin to try

some different weld bead types.

Loading...

Loading...