MAULE AEROSPACE TECHNOLOGY, INC.

MAINTENANCE MANUAL

FOR M-5-220C

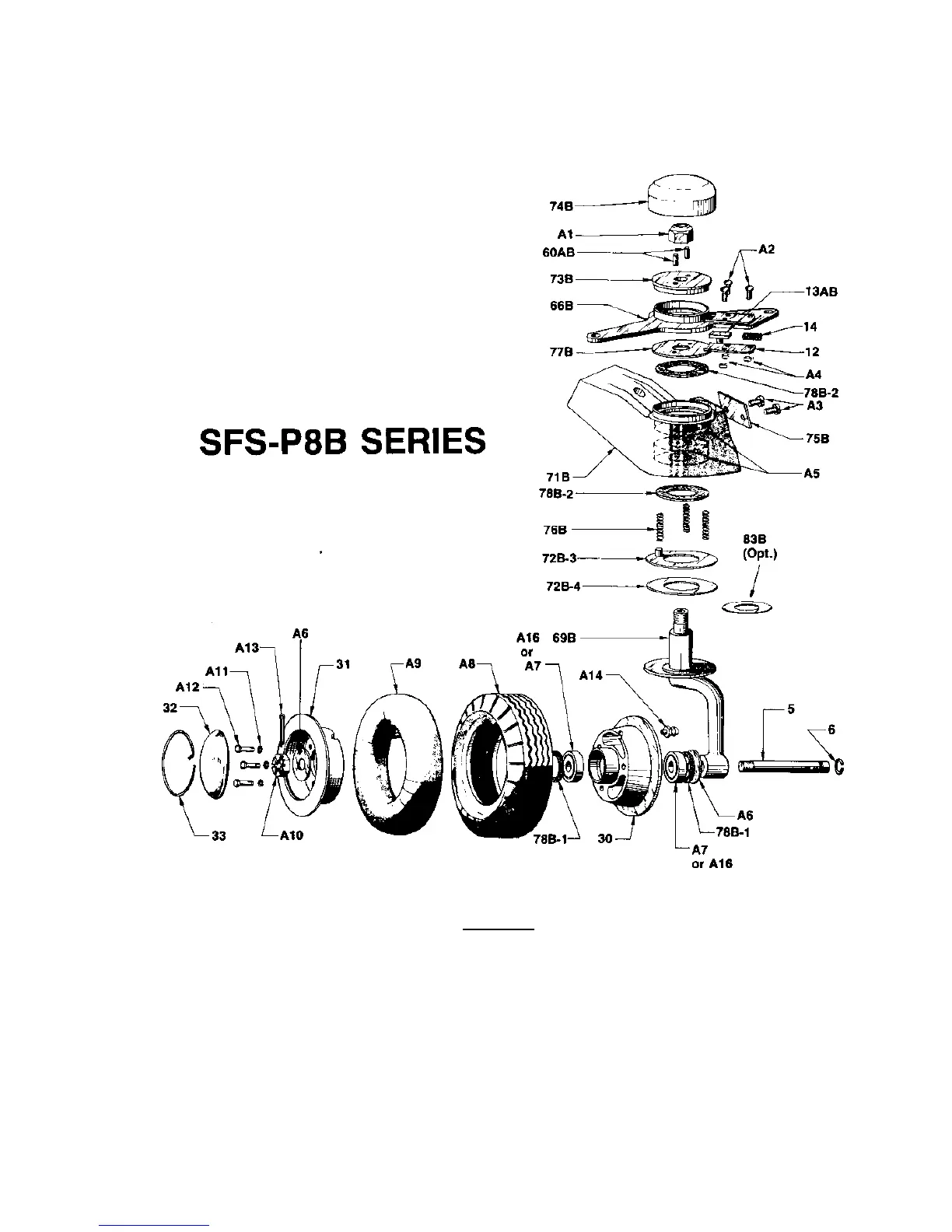

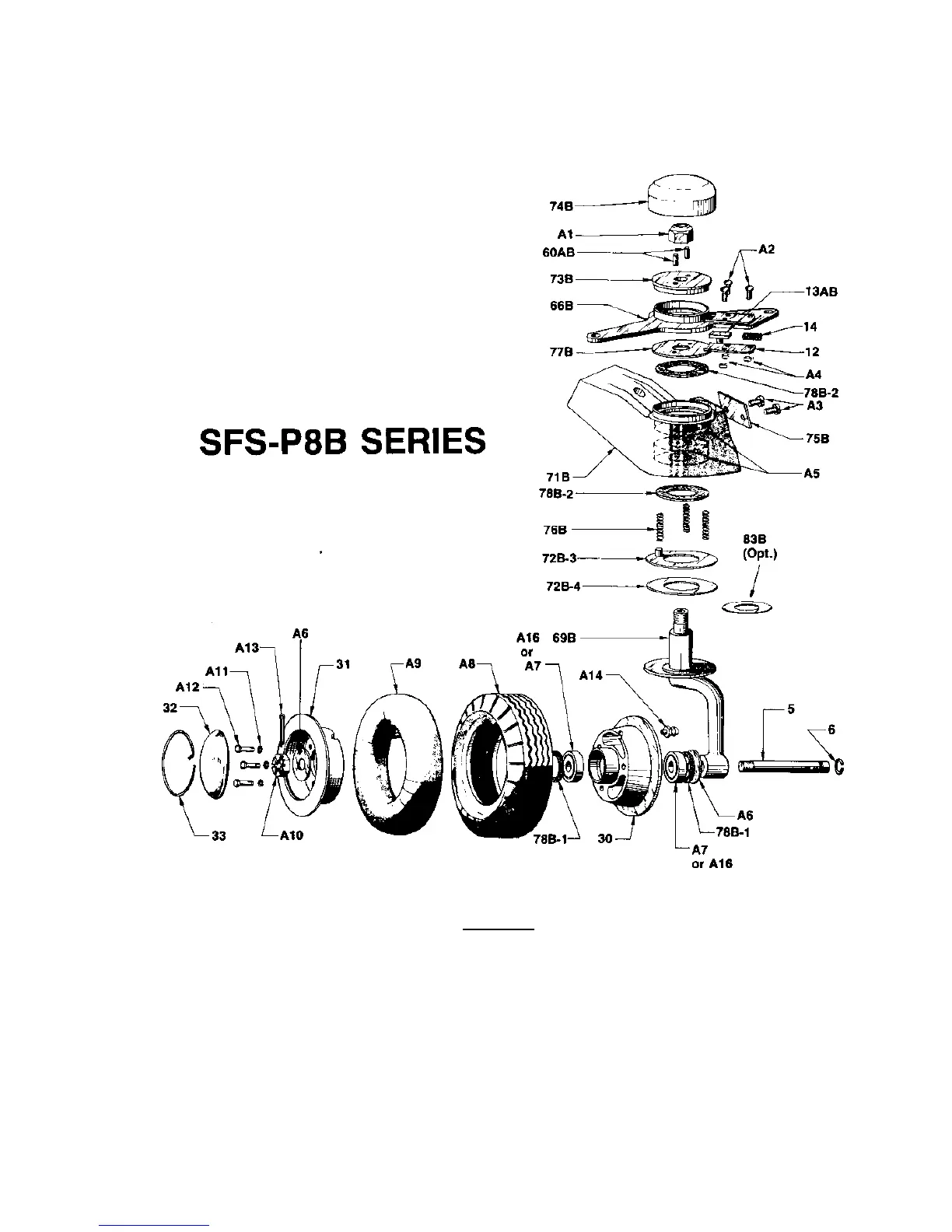

Rev. B 32/38

FIGURE 1

6.

Slide the lock pin subassembly over the threaded end of the fork spindle being careful

to keep the parts together. It will be necessary to retract lock pin (13AB) slightly to

clear wear plate (75B) as the assemblies are brought together.

7.

Thread on nut (A1) and torque to 15-20 foot pounds. Fork should rotate by hand, but

with some drag, which is normal and caused by the friction washer.

8.

Install cap (74B) with soft mallet. Check wheel rotation. There must be no play in the

bearings. Wheel should rotate with a slight drag.

Loading...

Loading...