DECLARATION OF CONFORMITY

Thisisadocument,orcollectionofdocuments,whichcertifiesthataproduct

conformstothestandardslaidoutbytechnicalstandardsand/orlegislation.

EMERGENCY DEVICE

A safety device which allows operations such as deliberate stoppages to be

performed in the event of a hazardous situation or machine malfunctions.

SAFETY DEVICE Device which eliminates or reduces risk.

SAFETY DISTANCE

The minimum distance from a danger zone at which a protective structure must

be placed.

FAULT When a machine/component ceases to perform the requested function.

Anomalous operation which does not meet the expected process conditions.

Collection of regular, predefined operations which aim to maintain themachine’s

operationinallaspectsasaconsequenceoftheintrinsicwearandtearfromuse.

Collection of operations necessary to use all functions of the machine.

OPERATOR

Person responsible for the installation, operation, adjustment, maintenance,

cleaning, repair or transport of the machine.

HAZARD/DANGER Source of possible injury or damage to health.

EXPOSED PERSON Any operator located entirely or partially within a danger zone.

Machine component used specifically to provide protection through a physical

barrier. A guard can work:

• On its own, and is therefore effective only whenclosed

• Incombinationwithaninterlockdevice,withorwithoutlockingoftheguard

FIXED GUARD

“Closed”, with reference to a fixed guard, means “kept in position”.

Guard kept in position (closed):

• Permanently (e.g. weldedetc.)

• Bymeansoffasteners(screws,boltsetc.)makingitimpossibletoremove/open

without the aid oftools.

A guard which is generally connected mechanically to the machine’s frame or a

nearby fixed guard (for example, via a hinge or guide), or which can be opened

without the use of tools.

RISK

Combination of the probability and seriousness of possible injury or damage to

health in a dangerous situation.

A risk which remains, above all during maintenance, installation and cleaning,

after the application of design and construction safety measures, of safety

List of all possible situations in which the machine may find itself during operation,

including all types of emergencies.

Distinctive element indicating the most general and significant machine data along

with its serial number.

USER The machine user.

DANGER ZONE

Anyareawithin/nearamachineinwhichapersonisexposedtotheriskofinjuries or

damage tohealth.

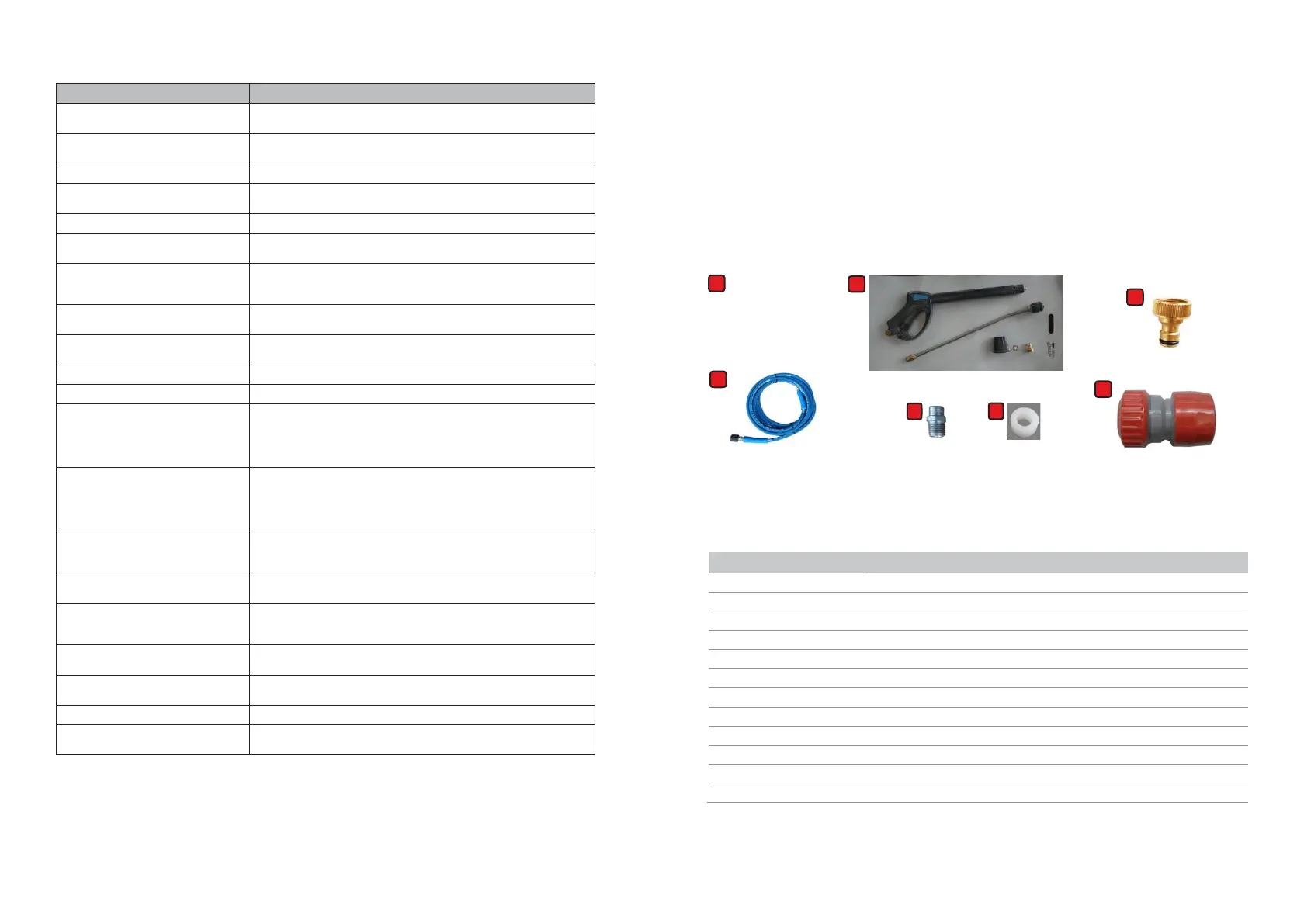

4.5 标准附件

标准设备包括:

• 高压软管R1 5/16“-长度10米。供应的机器能产生高达150巴的压力(A).

• 高压软管R2 5/16“或R2 3/8”-长度10米。供应产生超过150巴压力的机器(B).

• 喷枪和喷枪安装套件(C).

• 取水连接与过滤器(D).

• 管嘴,喷嘴(E).

• 压力表用聚四氟乙烯颗粒(F)。(适用于带有Mazzoni压力表保护系统的型号)

4.6 OPTIONALEQUIPMENT

The pressure washers can be equipped with further accessories depending on cleaning requirements:

ACCESSORY FUNCTION

Rotating nozzle To extend the working area of the jet.

Rotating brushes To remove stubborn dirt

Hose flushing kit For effective cleaning of blocked hoses.

Sandblasting kit For sand-blasting with high-pressure power.

Floor washing lance For cleaning floors.

Hour readout To obtain a readout of the machine’s working hours.

Hose reel For neat winding of the high-pressure hose.

Detergent tank For installation of a detergent tank on machines which are not supplied with one.

External detergent intake kit To be applied to the high-pressure outlet to draw in detergent from the tank.

Anti-scale filter To filter water at the pump intake.

Flue extension To raise the boiler exhaust flue outlet.

Detergent solenoid valve To remotely enable or disable detergent supply.

Loading...

Loading...