- 7 -

Axis1Axis1

Axis1Axis1Axis1Axis1Axis1

1"

7/8"

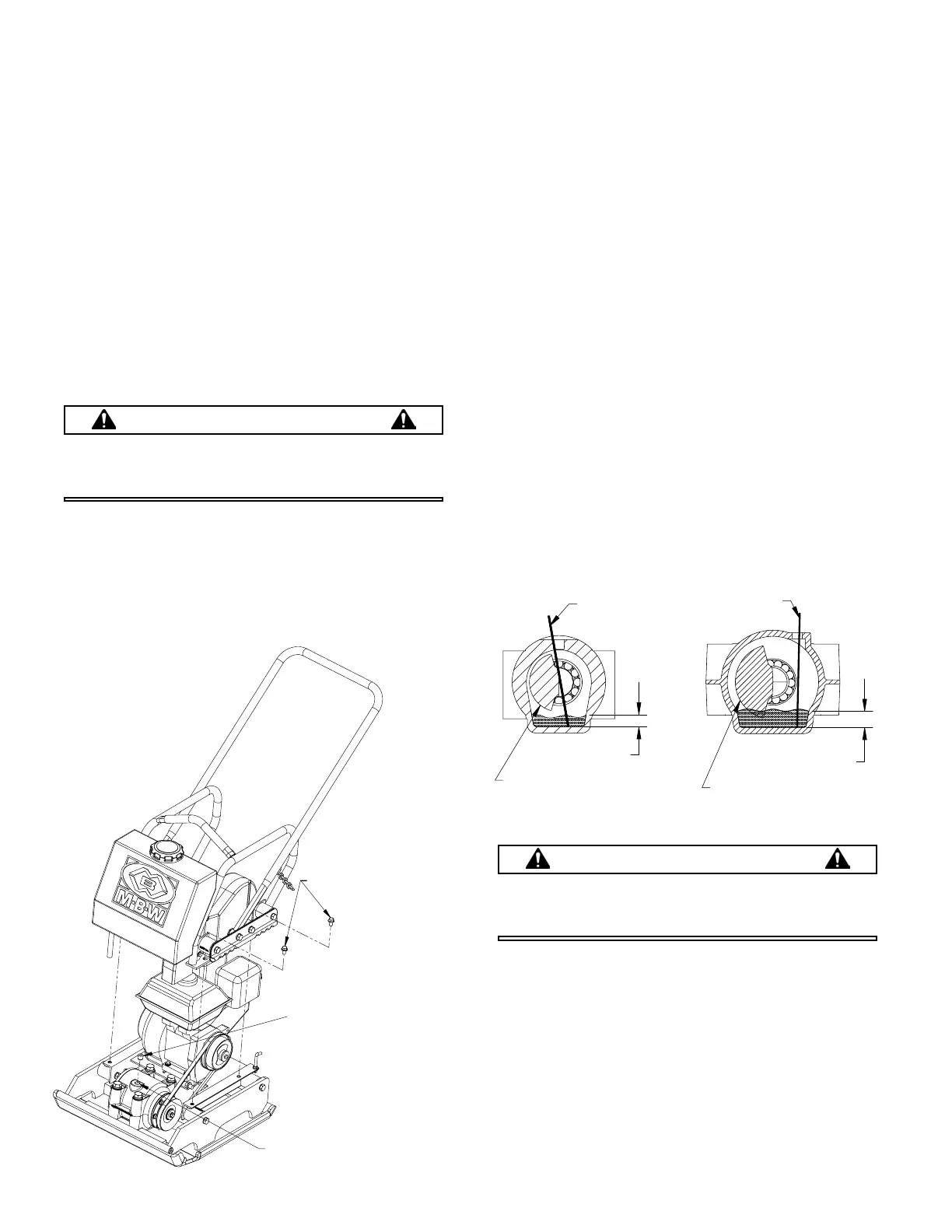

OIL LEVEL

.75 OIL LEVEL

2000 PLATE

DIP STICK

PLATE

EXCITER SHAFT

3550

FIGURE 2

EXCITER SHAFT

DIP STICK

2. Apply moderate thumb pressure to belt about half

way between pulleys. When properly adjusted the

belt should deflect approximately 3/8” (9mm). If the

belt is adjusted correctly reinstall belt guard and

hardware.

3. To adjust belt tension loosen (do not remove) the (4)

engine bolts.

4. Push engine towards the back of the plate. While

holding pressure on the engine retighten the (4)

engine bolts.

5. Recheck belt tension as described in step 2 and

readjust if necessary until the proper tension is

reached.

6. Reinstall roll cage assembly.

Checking Exciter Oil

WARNING

Exciter and oil is hot after machine has been

running. Allow machine to cool before servicing

unit.

1. Let exciter cool before checking oil.

2. Place plate on a level surface.

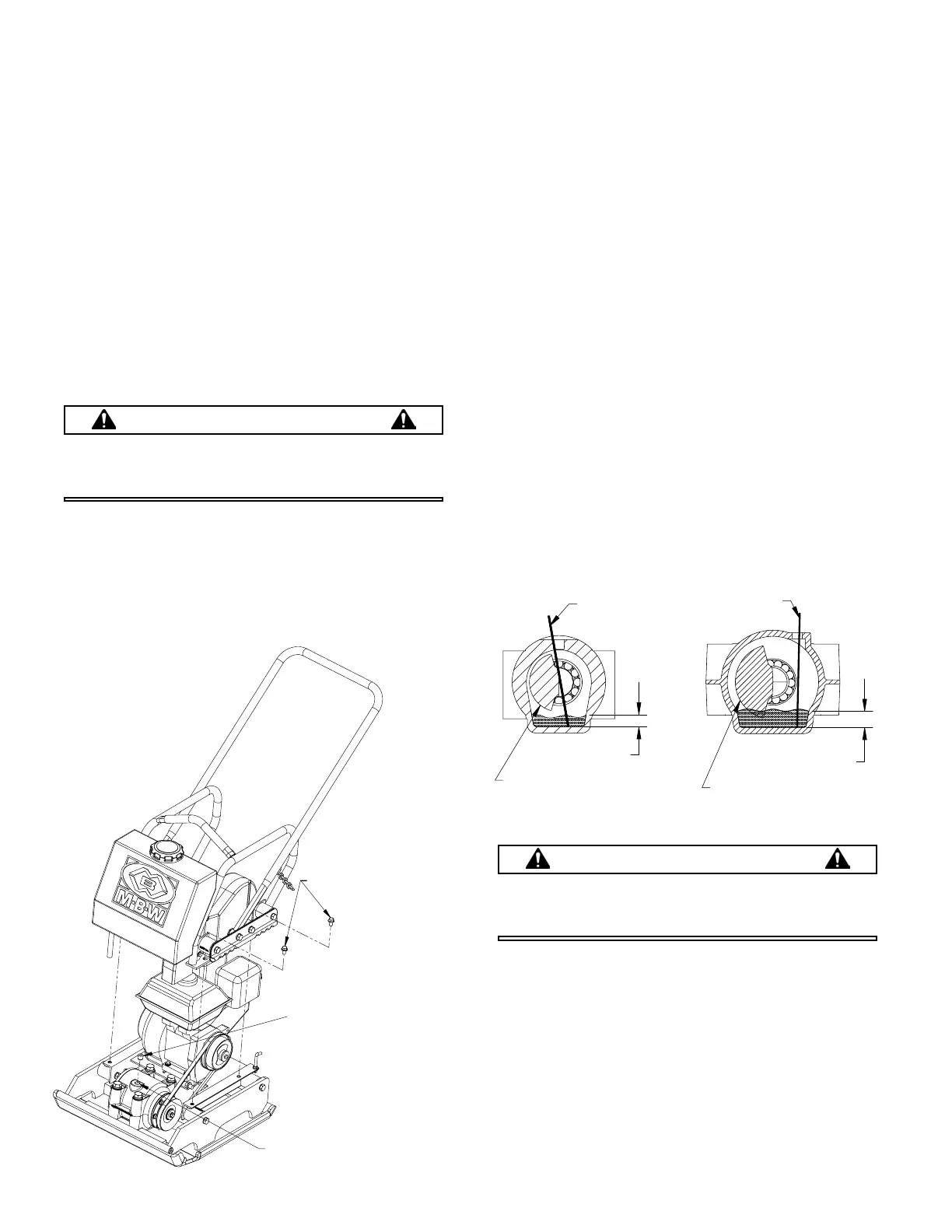

3. Remove roll cage assembly by removing (4) flange

screws securing roll cage to engine deck. If machine

is equipped with water tank disconnect hose from

spray bar on front of plate. Now entire roll cage

assembly, including roll cage, handle, water tank and

belt guard, can be removed (see Figure 1).

4. Clean all dirt and debris from exciter to prevent

contamination of exciter oil.

5. Remove pipe plug from top of exciter housing.

6. Rotate exciter shaft so a metal dip stick can be

inserted into exciter (see Figure 2).

7. Place a clean metal rod through the oil fill hole as

shown in figure 2.

8. Exciter should have approximately 3/4” (2000 plate)

7/8 to 1” (3550 plate) oil.

9. If oil need to be added, refer to Fluid Levels page of

this section for type of oil to be used. DO NOT

OVERFILL, over filling can cause excessive heat in

exciter.

10. Apply pipe sealant to pipe plug and reinstall into top

of exciter housing.

11. Reinstall roll cage assembly and re-attach hose to

spray bar.

Changing Exciter Oil

Exciter and oil is hot after machine has been

running. Allow machine to cool before servicing

unit.

1. Let exciter cool before changing oil.

2. Remove roll cage assembly by removing (4) flange

screws securing roll cage to engine deck. If machine

is equipped with water tank disconnect hose from

spray bar on front of plate. Now entire roll cage

assembly, including roll cage, handle, water tank and

belt guard, can be removed (see Figure 1).

3. Remove 1/2” hex head cap screws and lock washers

from side of bottom plate. Remove belt and engine

deck assembly. Refer to figure 3

OIL FILL/DRAIN HOLE

FIGURE 1

FLANGE SCREWS

PIPE PLUG

Loading...

Loading...