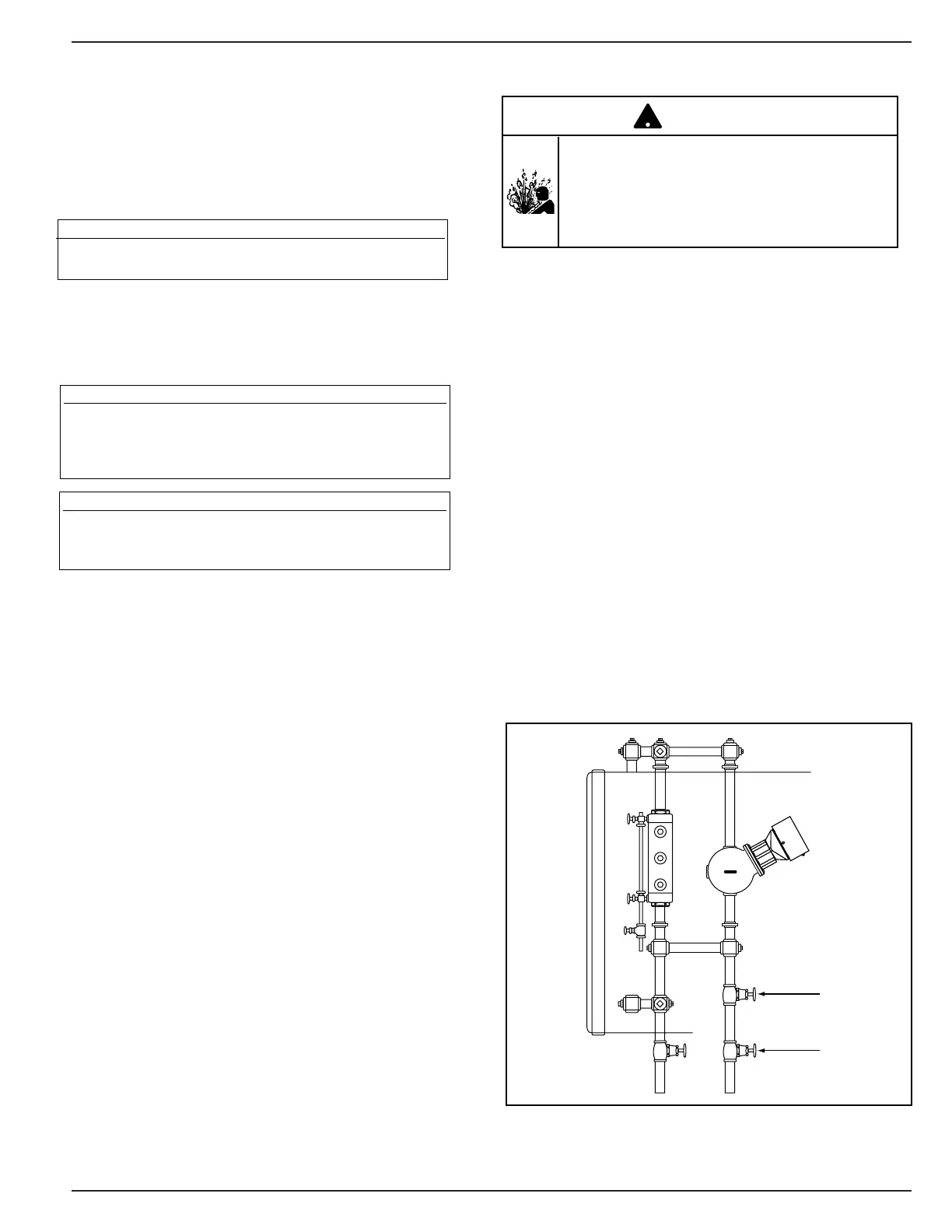

BLOW DOWN PROCEDURE:

Blow down the low water cut-off when the water level

is at its normal level (pump/valve off) and the burner

is on.

• Open upper valve (#1).

• Slowly open lower valve (#2).

• With both valves open the water level will drop in

the sight glass.

• When the water falls below the level of the middle

probe, the pump or valve should turn on.

• When the water falls below the level of the bottom

probe, the burner should turn off. NOTE: The Red

LED will turn on to indicate low water condition.

• Slowly close the lower valve (#2).

• The water level should begin to rise and the burner

should turn on (Red LED turns off) when the level is

at the middle probe. The pump or valve should turn

off when the water level rises above the top probe.

NOTE: On manual reset models, the red reset button

will need to be pressed after the water level is

restored to the level of the middle probe before the

burner will operate.

• Close the upper valve (#1).

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

CAUTION

MAINTENANCE

SCHEDULE:

Blow down control as follows when boiler is in

operation.

• Daily if operating pressure is above 15 psi.

• Weekly if operating pressure is below 15 psi.

Disassemble and inspect annually.

•

Remove sediment or debris from float chamber.

• Inspect and clean probes. Use a non-abrasive

cloth to clean probes and water-side of flange.

Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist such as rapid switch

cycling, surging water levels and use of water

treatment chemicals.

Replacement parts are available from your

local authorized McDonnell & Miller

Distributor. The use of parts or components other

than those manufactured by McDonnell & Miller

will void all warranties and may affect the units

compliance with listing or regulating agencies.

WARNING

DO NOT REMOVE PROBES FROM FLANGE. Replace probe

flange assembly if probe Teflon

®

insulation is broken, torn

or frayed.

NOTE

The probes may need to be inspected and cleaned more

frequently on systems with high raw water make-up.This

includes systems with no condensate return or untreated

boiler water.

NOTE

More frequent blow-down may be necessary due to

dirty boiler water and/or local codes.

Loading...

Loading...