Page 7I(+)/,F7.1F5:)J2,0/1(.0K)*:,50,)F5::)LM===M=NNM<O?ODItem 58494

P"IG'QR"%$'G$"$SGT"#'P)U%P' %$P'"UU"'%V$

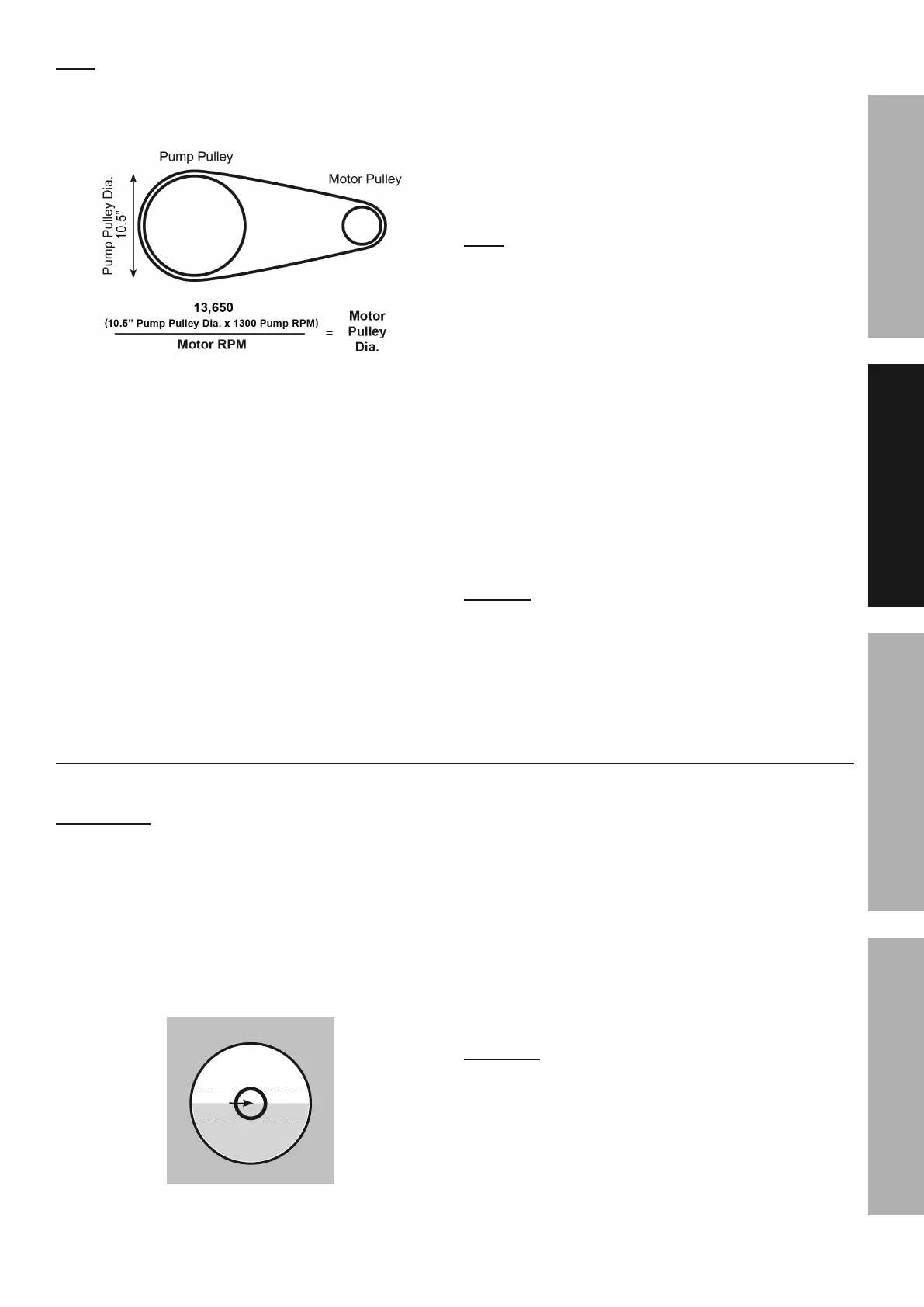

$(/,; Recommended pulley size is 3.75″.

To calculate needed pulley diameter, multiply

Pump Pulley Diameter (10.5″) by Pump RPM

(1300). Divide this number by motor RPM to get

the necessary motor pulley size. See Figure A.

I1E2+,)";))S5:F2:5/1(.)8(+)R(/(+)T2::,4

3. Pump Flywheel (31) must be in perfect alignment

with motor pulley. Misalignment between motor

and Pump can cause damage to equipment.

4. Verify that Pump Flywheel turns freely where

it overhangs the mounting surface.

5. Place a Type A Belt (not included) over Pump

Flywheel and motor pulley (not included).

6. Pull Compressor Pump until properly aligned,

and the belt is tight. Recheck alignment of

motor pulley, belt, and Pump Flywheel.

7. To mount Compressor Pump:

a. Use mounting holes in Compressor Pump

Base as a template to mark spots where four

holes will be drilled into mounting surface.

b. Move Compressor Pump aside, and drill four

5/16″ diameter holes in the mounting surface.

c. Move Compressor Pump back to mounting

position and secure each corner of the base

with a 5/16″ diameter Grade 5 (or better) bolt,

washer, lock washer, and nut (all not included).

d. Recheck Pump, belt, and pulley alignment.

Make adjustments as necessary.

$(/,; To test proper tension on belt, press down on belt.

There should be 1/2″ deflection or less at mid span.

8. Connect plumbing hardware (not included) from Air

Outlet to Air Destination (i.e., air pressure tank of

compressor, not included).Route tubing in shortest

possible path.

9. Depending on the air tool, you may need to incorporate

additional components, such as in-line oiler, filter, or

dryer (all sold separately), as shown in Figure C and

D on page 8 and 9. Consult your air tool’s manual for

needed accessories.

10. Install safety guard (not included) that surrounds motor

pulley, belt, and Pump Flywheel. Safety guard should

cover all sides of moving belt and pulleys. Safety guard

must have one inch clearance from all moving parts

and should be sturdy enough to prevent injury.

!5+.1.Ei Do not operate Air Compressor

Pump without safety guard in place.

11. Fill Compressor Pump Crankcase with appropriate

amount of Air Compressor Oil (sold separately).

S7,FY1.E)V1:)U,-,:

1. Check oil level before operating Air Compressor Pump.

%RTV#'"$'; Running Pump with no oil or low oil will

cause damage to equipment and void warranty.

2. Fill Pump Crankcase with synthetic non-

detergent Air Compressor Oil.

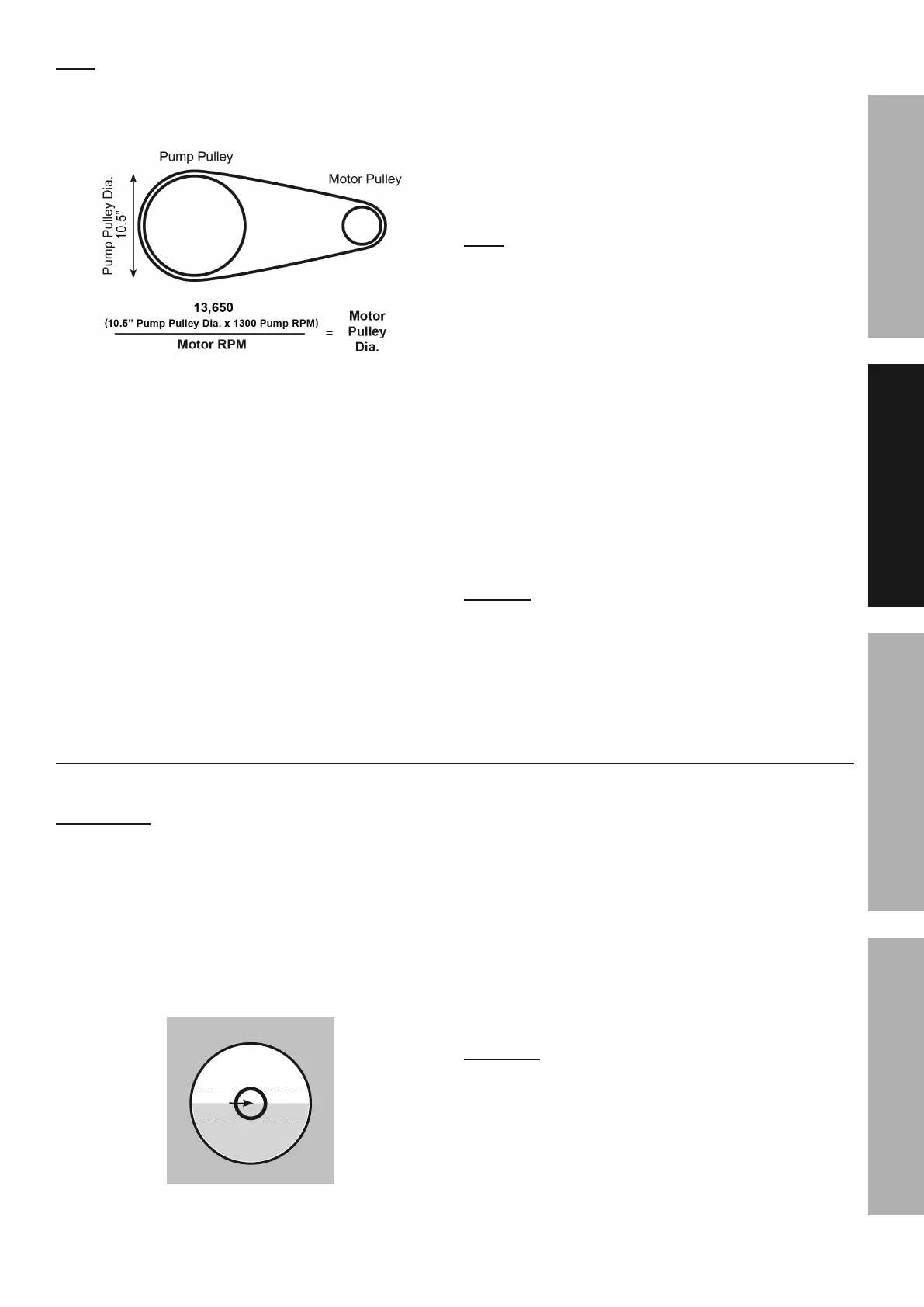

3. Oil level should be at the center of the FULL level

on the Oil Sight Glass (21). Add oil as needed to

maintain this level. Do not let oil level go below

center circle (LOW) and do not fill oil above center

circle (OVERFILL). See Figure B.

V@G#I%UU

UV!

I\UU

I1E2+,)W;)))V1:)P1E7/)&:500

4. To add oil:

a. Remove the Oil Fill Plug.

b. Using a funnel to avoid spills, pour enough

oil into the Pump Crankcase to reach

the “full” level in the Oil Sight Glass.

c. Replace the Oil Fill Plug.

5. If uncertain which oil to use for this compressor,

call Harbor Freight Tools customer service

at 1-888-866-5797 for assistance.

6. S75.E,)/7,)F(9*+,00(+)(1:)58/,+)/7,)81+0/)

7(2+)(8)20,)/()+,9(-,)5.4)6,B+10D

S"\'%V$i)'V)T#G@G$')%$f\#Q)I#VR)W\#$P;)

X().(/)566)(+)F75.E,)/7,)(1:)A71:,)

/7,)F(9*+,00(+)10)1.)(*,+5/1(.D))

"::(A)/7,)F(9*+,00(+)/()F((:)B,8(+,)+,*:5F1.E)(1:D

Loading...

Loading...