18 AGZ 026B through 130B IOMM AGZ-5

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in

service stations) to determine the freezing point. Obtain percent glycol from the

freezing point table below. It is recommended that a minimum of 25% solution by

weight be used for protection against corrosion or that additional compatible inhibitors

be added.

Concentrations above 35 percent do not provide any additional burst protection and

should be carefully considered before using.

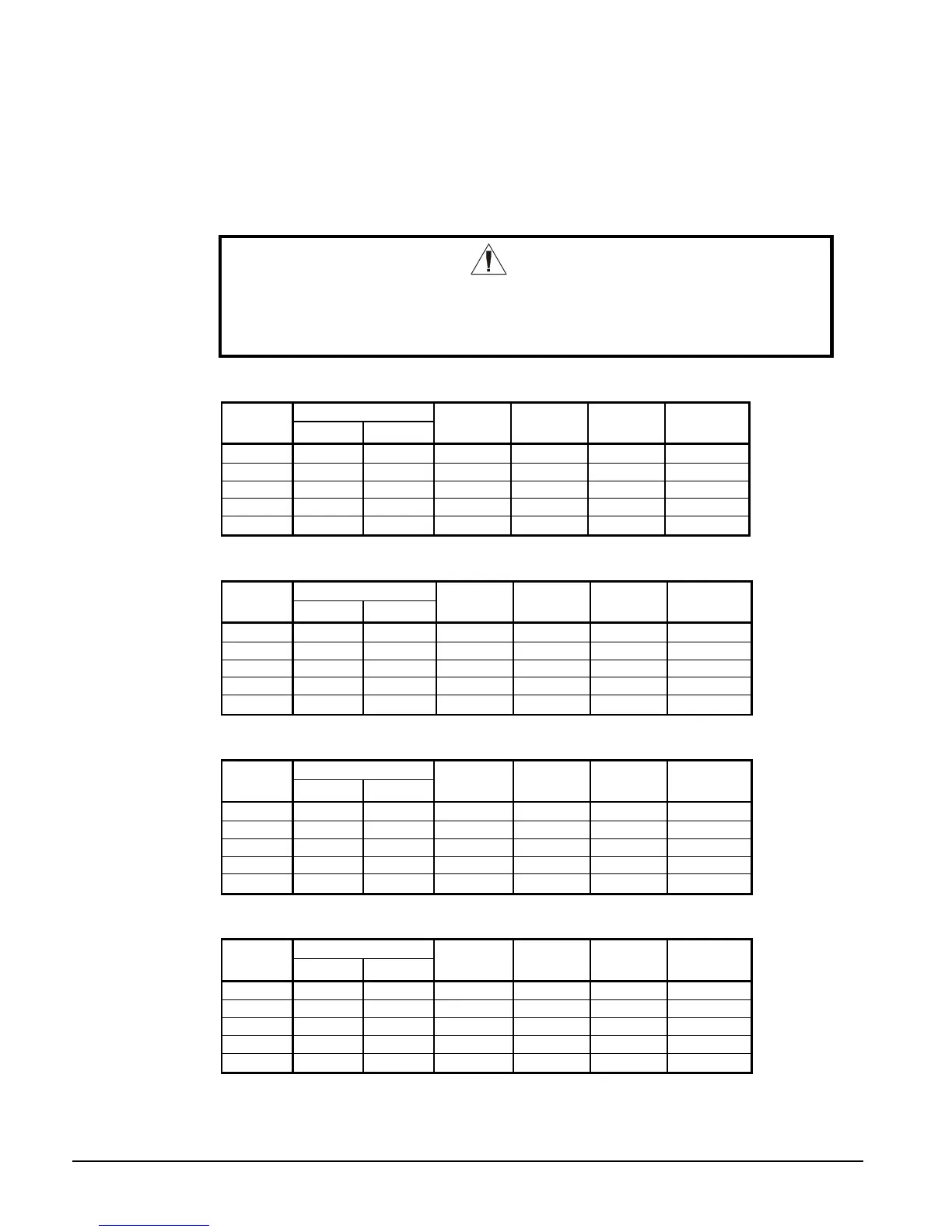

CAUTION

Do not use an automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors which will cause plating on the copper tubes

within the chiller evaporator. The type and handling of glycol used must be consistent

with local codes.

Table 7, Ethylene Glycol Factors for Models AGZ 026B to 070B

Freeze Point

% E.G.

o

F

o

C

Capacity Power Flow PD

10 26 -3.3 0.998 0.998 1.036 1.097

20 18 -7.8 0.993 0.997 1.060 1.226

30 7 -13.9 0.987 0.995 1.092 1.369

40 -7 -21.7 0.980 0.992 1.132 1.557

50

-28 -33.3 0.973 0.991 1.182 1.791

Table 8, Propylene Glycol Factors for Models AGZ 026B to 070B

Freeze Point

% P.G.

o

F

o

C

Capacity Power Flow PD

10 26 -3.3 0.995 0.997 1.016 1.100

20 19 -7.2 0.987 0.995 1.032 1.211

30 9 -12.8 0.978 0.992 1.057 1.380

40 -5 -20.6 0.964 0.987 1.092 1.703

50

-27 -32.8 0.952 0.983 1.140 2.251

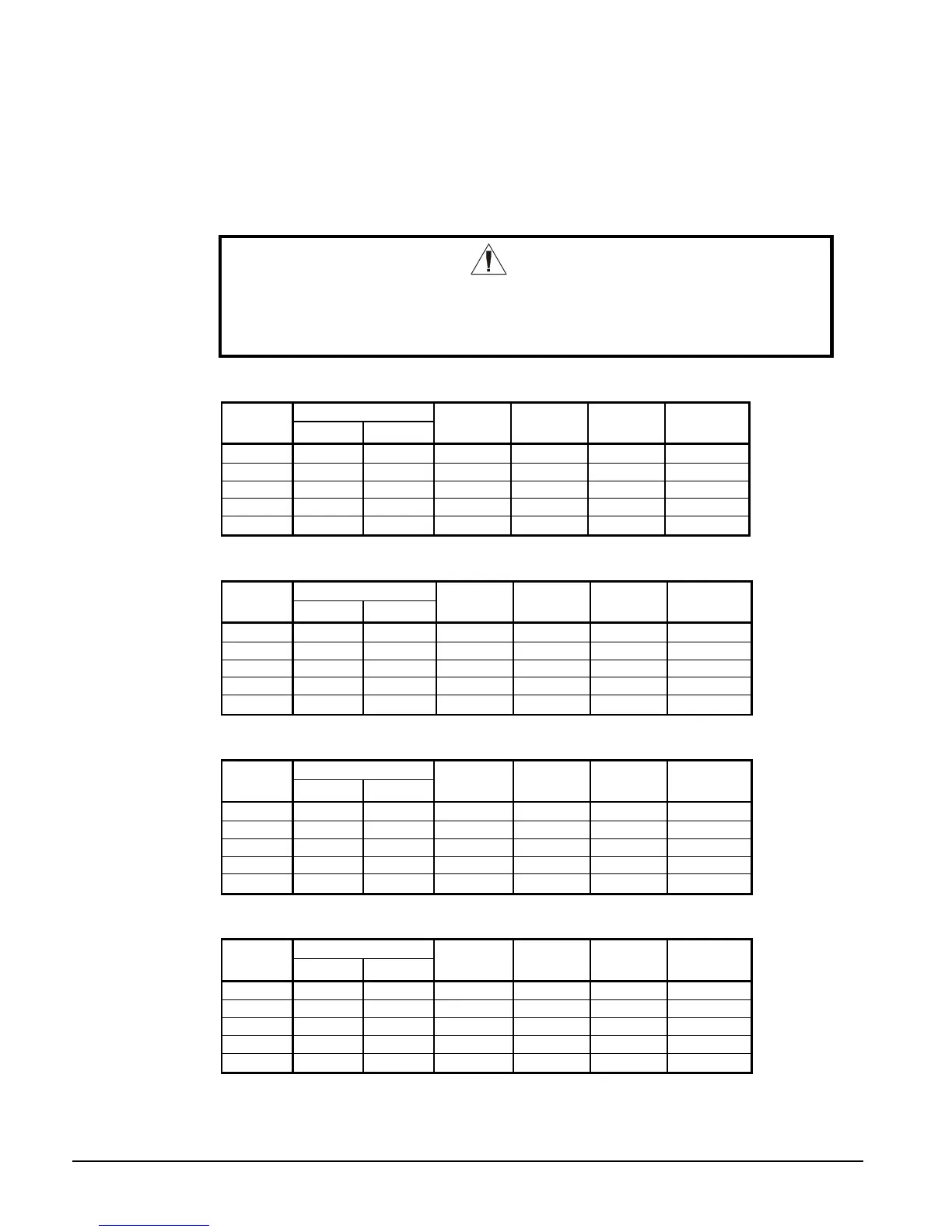

Table 9, Ethylene Glycol Factors for Models AGZ 075B to 130B

Freeze Point

% E.G.

o

F

o

C

Capacity Power Flow PD

10 26 -3.3 0.994 0.998 1.038 1.101

20 18 -7.8 0.982 0.995 1.063 1.224

30 7 -13.9 0.970 0.992 1.095 1.358

40 -7 -21.7 0.955 0.987 1.134 1.536

50

-28 -33.3 0.939 0.983 1.184 1.755

Table 10, Propylene Glycol Factors for Models AGZ 075B to 130B

Freeze Point

% P.G.

o

F

o

C

Capacity Power Flow PD

10 26 -3.3 0.988 0.996 1.019 1.097

20 19 -7.2 0.972 0.992 1.035 1.201

30 9 -12.8 0.951 0.987 1.059 1.351

40 -5 -20.6 0.926 0.979 1.095 1.598

50

-27 -32.8 0.906 0.974 1.142 2.039

Loading...

Loading...