70 AGZ 026B through 130B IOMM AGZ-5

NOTE: The inverter 7-segment display shows lower case “b” and “d,” meaning the same as the

upper case letters “B” and “D” used in this manual (for uniformity “A to F”).

NOTE: The Store Key saves the edited parameter (shown in the display) to the EEPROM in the

inverter, regardless of the programming device. Upload and download of parameters is

accomplished through a separate command—do not confuse Store with Download or Upload.

Troubleshooting Tips

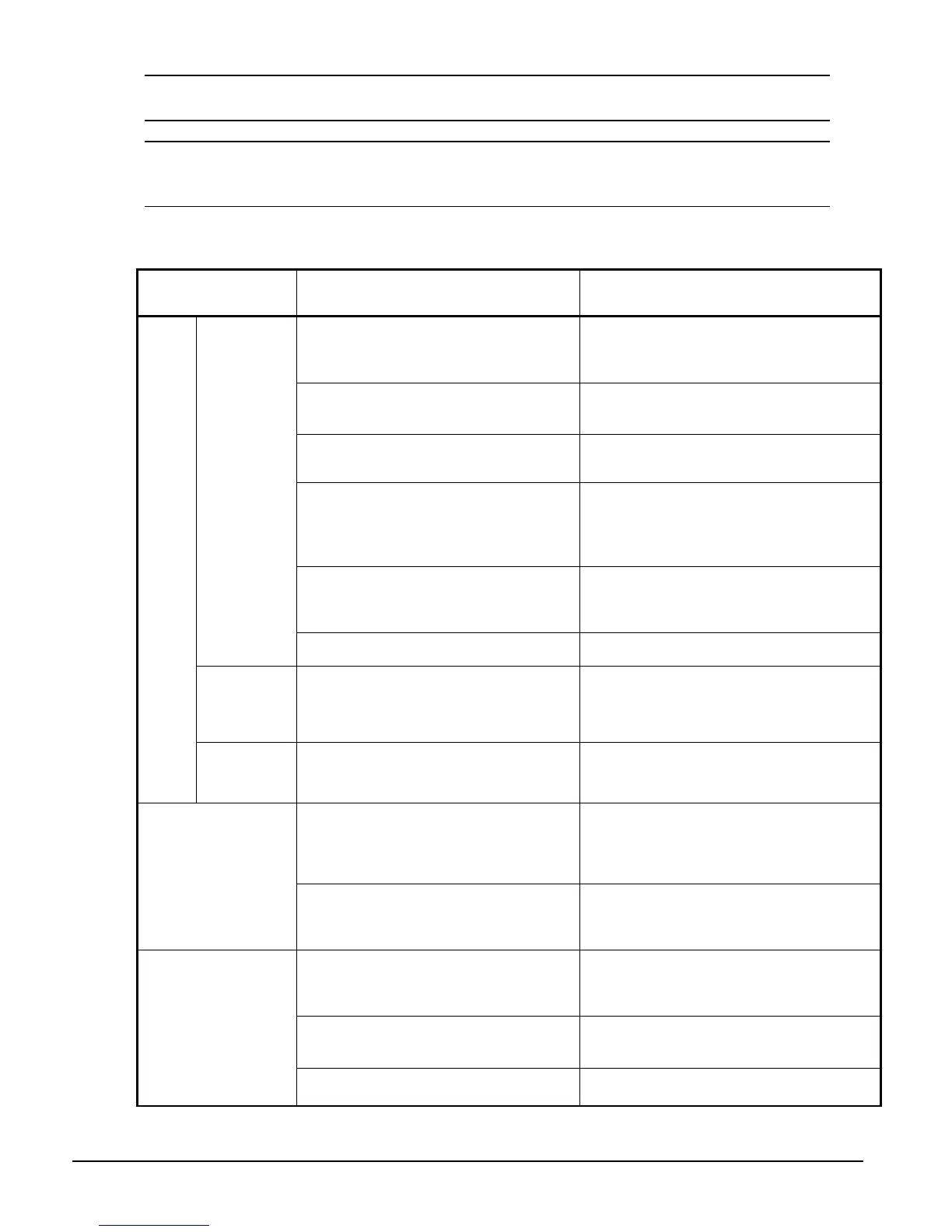

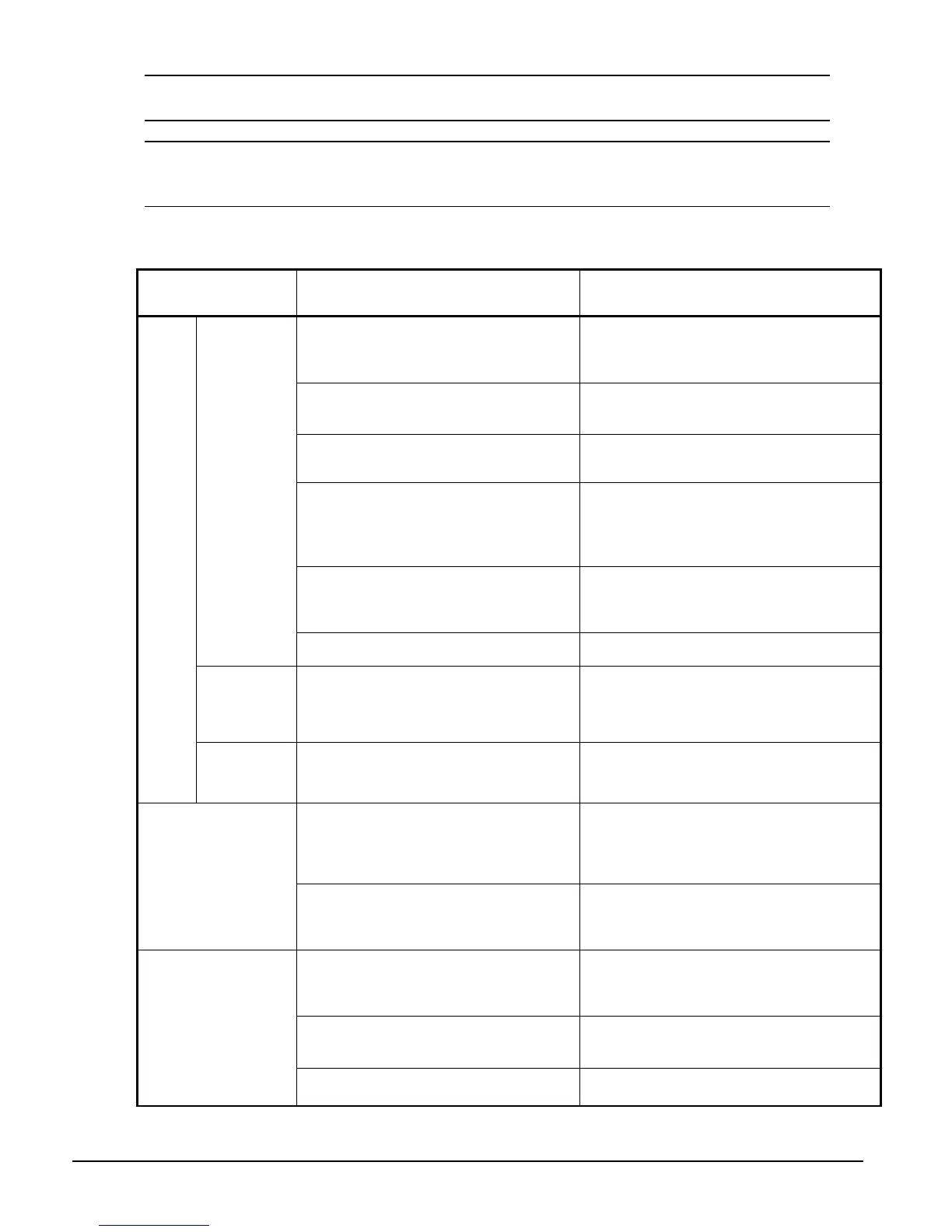

The table below lists typical symptoms and the corresponding solution(s).

Symptom

Condition

Probable Cause Solution

• Is the frequency command source A_01

parameter setting correct?

• Is the Run command source A-02

parameter setting correct?

• Make sure the parameter setting A-01 is

correct.

• Make sure the parameter setting A-02 is

correct.

• Is power being supplied to terminals [L1],

[L2], and [L3/N]? If so, the POWER lamp

should be ON.

• Check terminals [L1], [L2], and [L3/N], then

[U/T1], [V/T2], and [W/T3].

• Turn ON the power supply or check fuses.

• Is there an error code E X X displayed? • Press the Func. key and determine the error

type. Eliminate the error cause, then clear the

error (Reset).

• Are the signals to the intelligent input

terminals correct?

• Is the Run Command active?

Is the {FW] terminal (or [RV]) connected to

[P24] (via switch, etc.)

• Verify the terminal functions for C_01 – C_05

are correct.

• Turn ON Run Command enable.

• Supply 24V to {FW] or [RV] terminal, if

configured.

• Has the frequency setting for F_01 been

set greater than zero?

• Are the control circuit terminals [H], [O],

and [L] connected to the potentiometer?

• Set the parameter for F_01 to a safe, non-

zero value.

• If the potentiometer is the frequency setting

source, verify voltage at [O] > 0V.

The inverter

outputs [U],

[V], [W] are

not supplying

voltage.

• Is the RS (reset) function or FRS (free-run

stop) function ON?

• Turn OFF the command(s).

Inverter

outputs [U],

[V], [W] are

supplying

voltage.

• Is the motor load too heavy? • Reduce load, and test the motor

independently.

The

motor

will not

run.

The optional

remote

operator is

used (SRW).

• Are the operational settings between the

remote operator and the inverter unit

correct?

• Check the operator type setting.

• Are the connections of output terminals

[U/T1], [V/T2], and [W/T3] correct?

• Is the phase sequence of the motor

forward or reverse with respect to [U/T1],

[V/T2], and [W/T3]?

• Make connections according to the phase

sequence of the motor. In general:

FWD = U-V-W, and

REV = U-W-V.

The direction of the motor

is reversed.

• Are the control terminals [FW] and [RW]

wired correctly?

• Is parameter F_04 properly set?

• Use terminal [FW] for forward, and [RV] for

reverse.

• Set motor direction in F_04.

• If using the analog input, is the current or

voltage at [O] or [OI]?

• Reduce the load.

• Heavy loads activate the overload restriction

feature (reduces output as needed).

• Is the load too heavy? • Reduce the load

• Heavy loads activate the overload restriction

feature (reduces output as needed).

The motor speed will not

reach the target

frequency (desired

speed).

• Is the inverter internally limiting the output

frequency?

• Check max frequency setting (A_04).

• Check frequency upper limit setting (A_61).

Continued on next page.

Loading...

Loading...