GPI109

Revision: 12/16/14

GPI109

Revision: 12/16/14

12 13

TO RECLINE:

1. Attach stabilizer bar if not already in place.

2. Inform the wheelchair occupant that you are about to recline the back of the chair.

3. Make sure the wheelchair is occupied and is on a level surface before reclining.

4. Stand behind the wheelchair and grasp both handles rmly. Make sure both back canes and handles are at the same angle BEFORE releasing

the levers.

5. Lift up on the handles and squeeze the release levers.

6. SLOWLY pull back on the back assembly while squeezing the release levers.

7. When the back reaches the desired angle, SLOWLY let go of the release levers.

8. Keep push canes even at all times

TO INCLINE

(DECREASE THE ANGLE OF RECLINE OR RETURN THE BACK TO THE UPRIGHT POSITION):

1. Lift up on the handles and squeeze the release levers. Be prepared to support the occupant’s weight.

2. SLOWLY raise the back of the chair while continuing to squeeze the release levers.

3. Stop at the desired height or when the back is fully upright.

4. Release the release levers.

ADJUSTING THE RECLINING MECHANISM

Adjustments to the reclining mechanism should only be performed by a qualied wheelchair technician. If the seat back does not recline/incline

smoothly, or if the seat back does not lock into place easily, DO NOT use the reclining feature until the chair has been serviced.

SAFETY INSPECTION & MAINTENANCE

It is highly recommended that the wheelchair be taken to a qualified dealer annually for a thorough inspection

and maintenance / repair service.

GENERAL CARE

• Wipe off chrome / aluminium parts at least once per week using a clean, soft cloth.

• Clean all metal parts with auto wax or similar products.

• Dry the chair immediately if exposed to moisture.

• Do not use abrasive cleanser or materials that will scratch the nish of the chair.

• Clean the upholstery with a mild soap solution, rinse and wipe dry.

• Clean the hand grips with water only and dry thoroughly. Use of soap or ammonia based cleaning solutions may loosen the grips.

GENERAL:

Inspect the entire wheelchair for broken parts, sharp edges and loose fasteners. Ensure that everything works and the chair rolls straight without

drag and does not pull to one side. Replace or tighten parts as needed. Inspect for bent frame and crossbars.

Frame and Cross braces:

Check that the frame and cross braces are not bent or dented. Check the tubing for cracks and rust. If such issues are found, take the wheelchair

to your local service dealer.

UPHOLSTERY:

Inspect for any rips, tears or worn spots and replace as necessary. Inspect the upholstery screws and assure that all are present and tight. Torn or

worn upholstery may not support the user’s weight and could result in a fall with serious bodily injury.

ARMRESTS:

Check for cracks, looseness, or sharp edges.

HAND GRIPS:

Ensure the hand grips are tight and secure on the handles. They should not move or twist.

FOOTRESTS / LEGRESTS:

Ensure the legrest assembly release works properly. Ensure the assembly automatically locks securely into place when attached and will not

accidentally unlock.

FRONT CASTOR FORKS:

Verify the forks swivel freely without binding. Check to ensure the castors roll freely by lifting the chair and spinning the castor. The castor should

come to a gradual stop. If the nut is too loose, the castor will utter or shimmy. If the nut is too tight, the chair will be difcult to steer. Check the

bearings and clean the fork stem housing.

FRONT CASTORS AND REAR WHEELS:

Ensure the castor/wheel axle and nuts are tight. The fork housing and the rear and front wheels are constructed with low maintenance, sealed

bearings to keep dirt out and increase the durability of the chair. Bearings are also protected with an additional bearing spacer component. Check

that the wheels are not warped, cracked or otherwise damaged and the spokes are not broken. Replace as needed. Assure that the wheels spin

freely. Replacement and maintenance of wheel bearings should be completed by a qualied wheelchair technician only.

FRONT AND REAR TIRES:

Solid tires require minimal maintenance. They should occasionally be cleaned with a damp cloth. Replace the tires if they become cracked,

excessively worn, or have at spots.

RECLINER (FOR MODELS EQUIPPED):

Inspect the reclining mechanisms to ensure they are clean and work freely. Ensure that the stabilizer bar locks securely into place.

MAINTENANCE

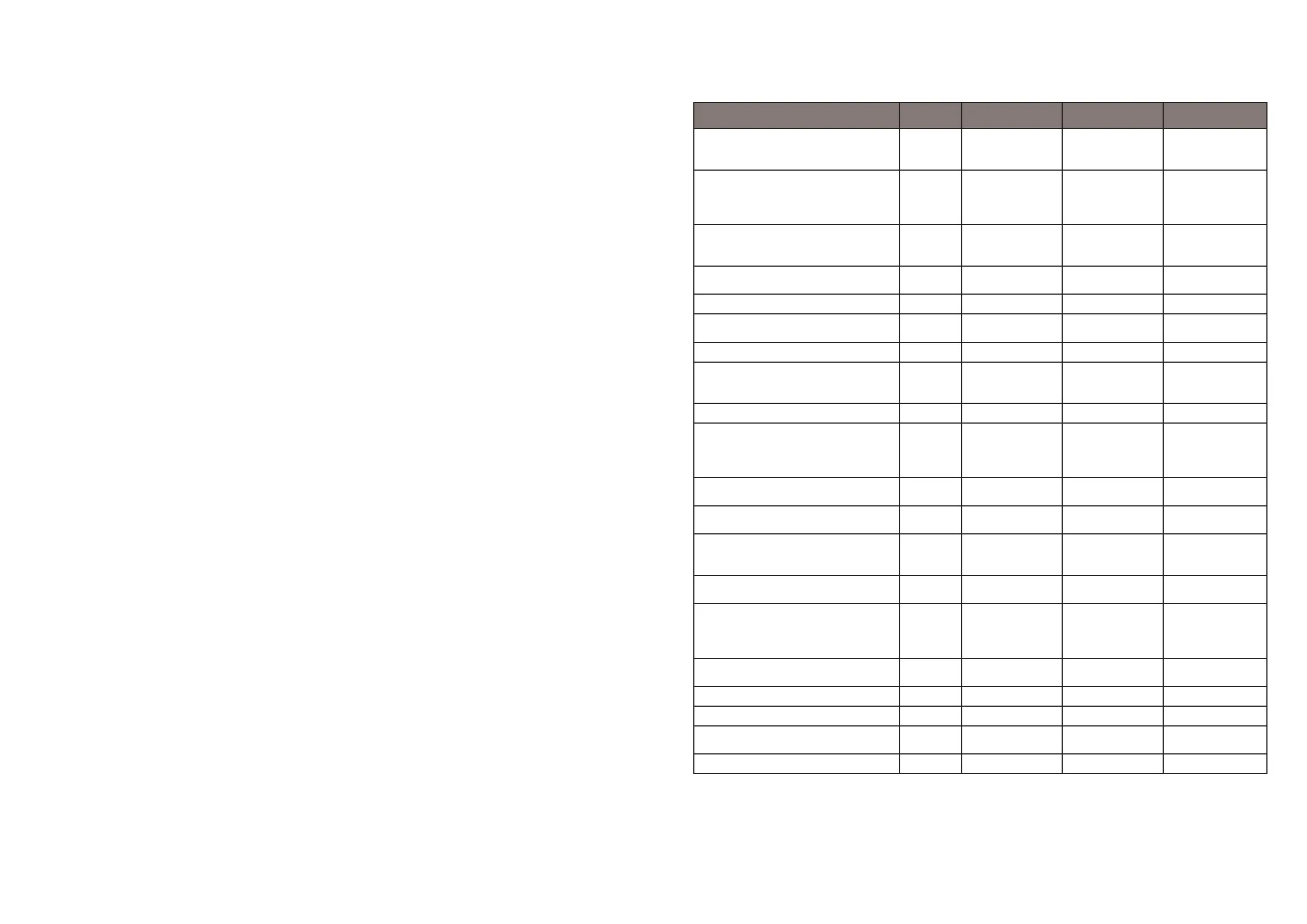

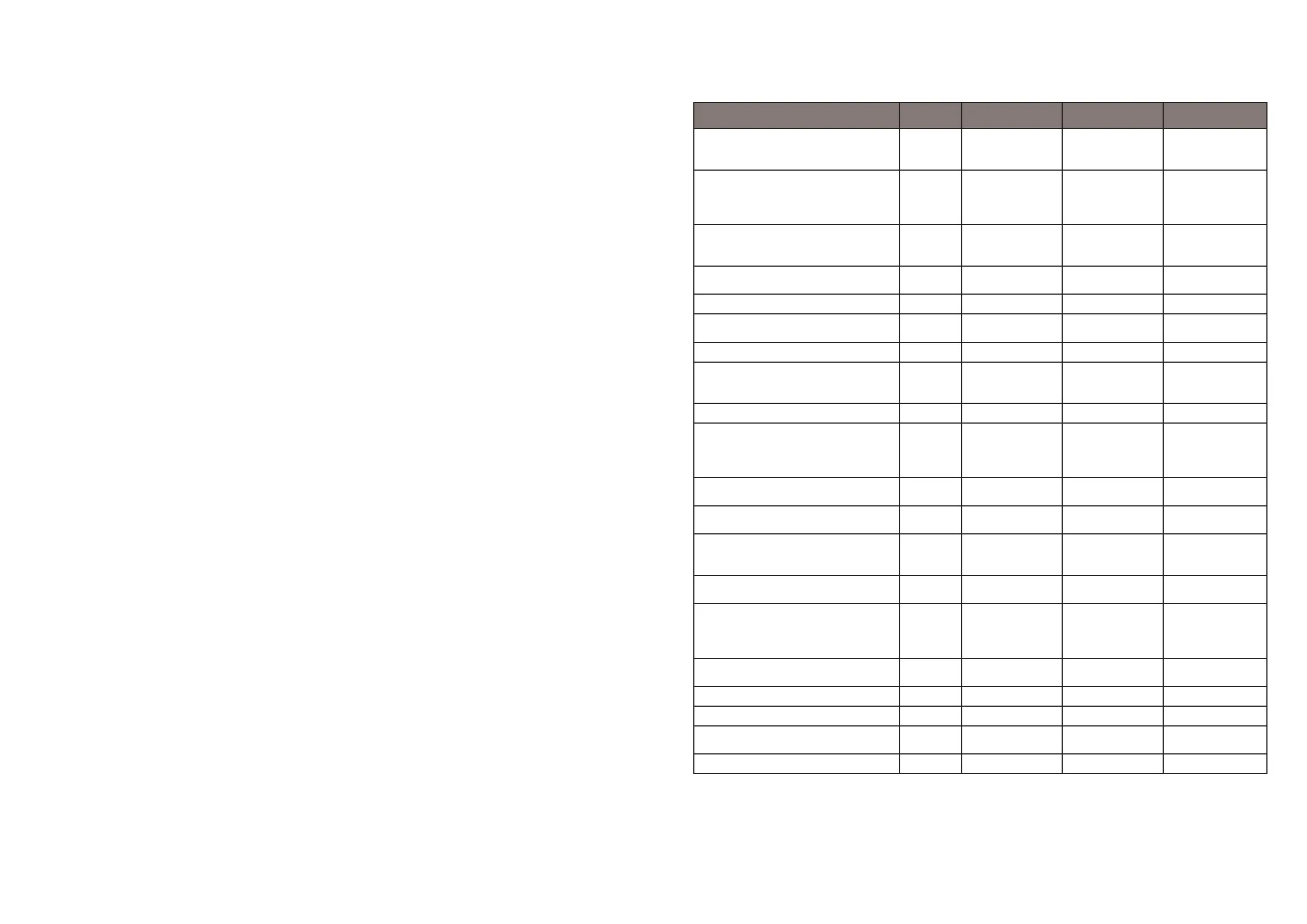

SAFETY INSPECTION CHECKLIST

ITEM INITIALLY

INSPECT / ADJUST

WEEKLY

INSPECT / ADJUST

MONTHLY

INSPECT / ADJUST

PERIODICALLY

GENERAL

Chair rolls straight.

(no excessive pull to one side)

X X

CLEANING

Wipe chrome parts with clean, soft cloth.

Auto wax / similar product on metal parts.

Clean upholstery with mild soap solution.

X

Use only water on hand grips.

Dry chair immediately when wet.

Do not use abrasive cleansers or cloths.

X

FRAME & CROSS BRACES

Inspect for loose or missing hardware. X X

Inspect for bent frame or cross braces.

X X

SEAT AND BACK UPHOLSTERY

Inspect for rips or sagging. X X

Inspect for loose or broken hardware.

X X

RECLINER

Inspect reclining mechanism to ensure they are

clean and work freely.

X X

Ensure stabilizer bar engages securely. X X

FRONT CASTERS AND REAR WHEELS

Inspect wheel / fork assembly for proper tension

by lifting the chair and spinning the caster. It

should come to a gradual stop.

X X

Loosen locknut if wheel wobbles / tighten

locknut if wheel binds to a stop.

X X

Ensure wheel bearings are clean and free of

moisture.

X X

REAR WHEELS

No excessive side movement or binding when

chair is lifted and wheels are spun.

X X

FRONT AND REAR TIRES

Inspect for flat spots and wear. X X

HAND GRIP WHEEL LOCKS

(If equipped) Test in both complete and

intermittent lock positions. Ensure the chair

does not move when the locks are engaged.

X X

WHEEL LOCKS

Do not interfere with tires when rolling. X X

Pivot points free of wear and looseness. X X

Wheel locks are easy to engage. X X

LAP BELT

Inspect for secure attachment. X X

Inspect for worn or frayed belt. X X

Loading...

Loading...