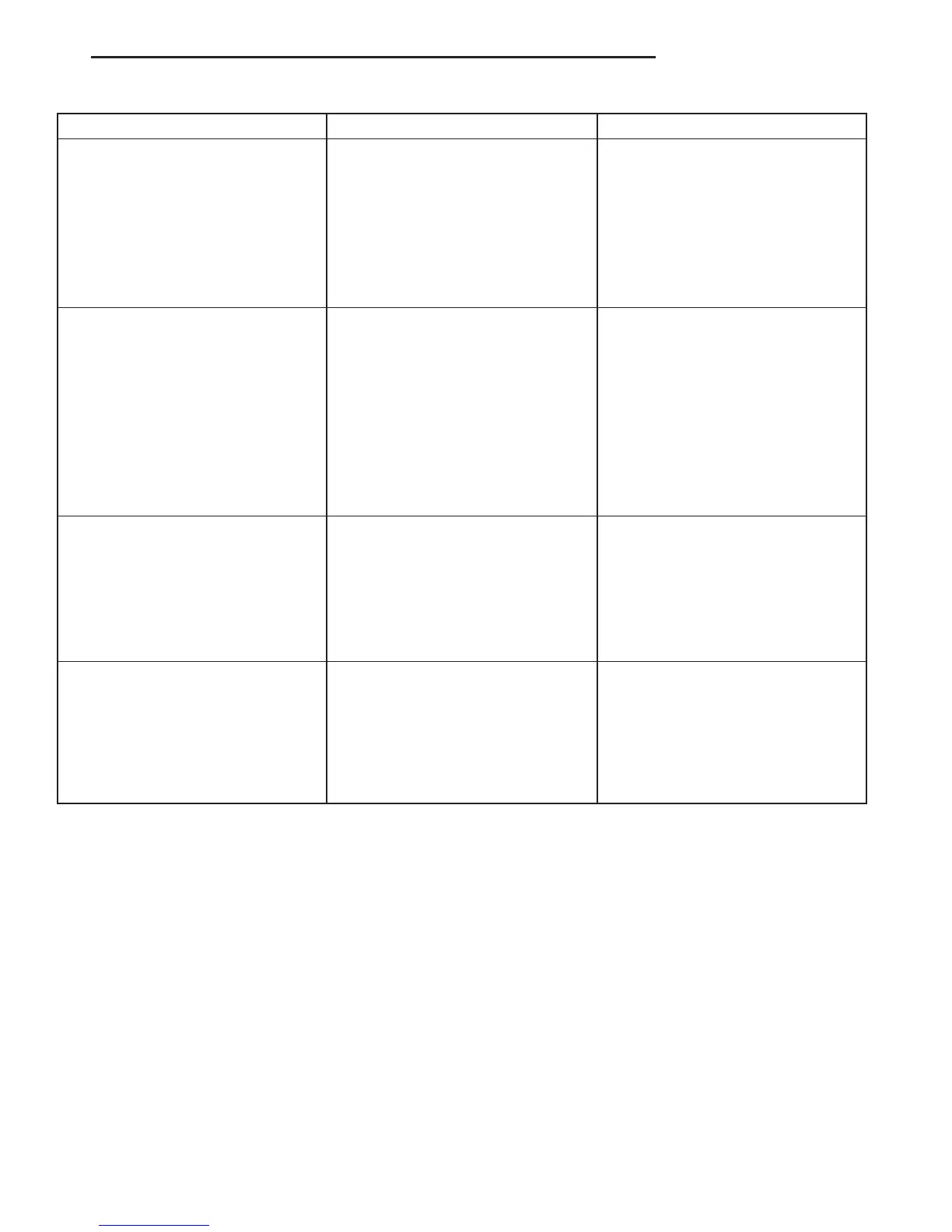

CONDITION POSSIBLE CAUSES CORRECTION

BELT BROKEN

(Note: Identify and correct problem

before new belt is installed)

1. Incorrect belt tension 1. Replace Inspect/Replace

tensioner if necessary

2. Tensile member damaged during

belt installation

2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component

and belt

NOISE (Objectional squeal, squeek,

or rumble is heard or felt while drive

belt is in operation)

1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration

5. Locate defective driven

component and repair

6. System resonent frequency

induced vibration

6. Vary belt tension within

specifications

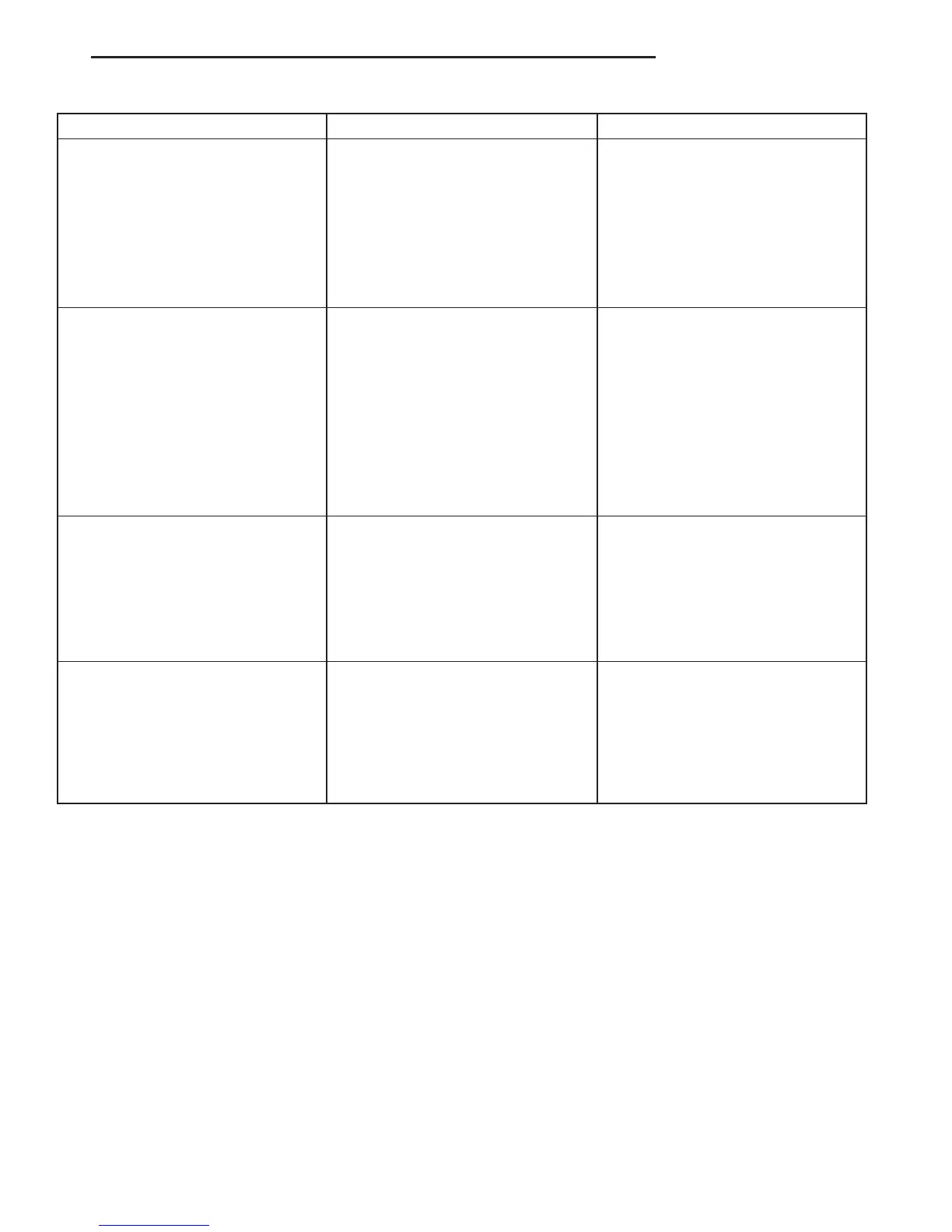

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)

1. Tension sheeting contacting

stationary object

1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age

2. Replace belt

3. Tension sheeting splice has

fractured

3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)

1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix

4. Replace belt

VA ACCESSORY DRIVE 7 - 7

DRIVE BELTS (Continued)

Loading...

Loading...