Doc# M9162• REV AB (April 2019) Page 2 of 12

drill equipped with a magnec base but care must be taken so that the tapped and threaded

hole is perpendicular to the machined surface. The transmier must make contact all the way

around its base surface. Contact Metrix for more detailed counter bore instrucons.

If installing a transmier with a standard 1/4 inch NPT stud, drill a hole using a 7/16 inch bit, 5/8-

7/8 inch deep. Then tap using a 1/4 - 18 NPT (tapered pipe tap). Hand-ghten the transmier

and then turn an addional 1 to 2 turns using a wrench on the wrench ats. Do not use a pipe

wrench. A pipe wrench can apply extreme forces to the body and potenally damage electronic

components. A minimum of ve (5) threads of engagement should be made. A 1/4 inch to 1/2

inch NPT bushing is available for mounng the transmier in exisng 1/2 inch NPT holes. Also,

a Metrix model 7084 Flange Adapter can be used between the transmier and the machine

surface when there is not enough surface thickness to drill and tap a hole. The ange adaptor

mounts with three small screws.

If installing a transmier with one of the straight machined thread sizes, follow standard drill and

tap procedures. Do not drill a hole larger that the counter bore pilot diameter before using the

counter bore to prepare the machine surface. Drill out the hole with the correct tap drill size

aer preparing the surface.

The sensive axis of the transmier is in line with the mounng stud. The transmier can be

oriented in any (0 to 360 degree) posion.

3. WIRING

3.1 General

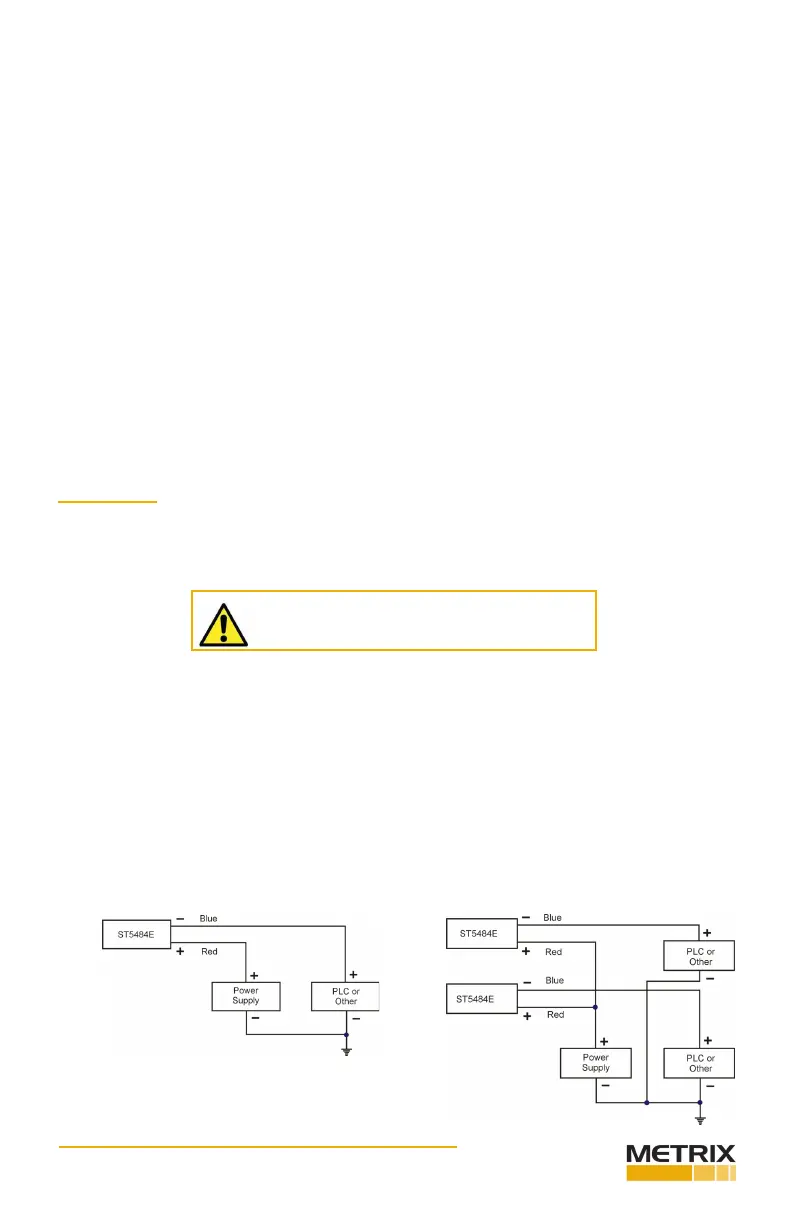

The ST5484E is connected like other loop powered transmiers. The following is a summary

based on area designaons.

Connect the eld wiring in accordance with the appropriate poron of Figure 1.

The ST5484E terminal block opon must be used with the following conductors specicaon:

• 14-24 AWG solid copper conductors OR

• 20-26 AWG stranded copper conductors

The ST5484E transmier requires a minimum of 11 VDC for proper operaon. This is the mini-

mum voltage required at the transmier (not the power supply), aer all other voltage drops

across eld wiring and receiver input impedance have been accounted for with the maximum

20mA of loop current owing. The minimum loop power supply voltage required is therefore 11

VDC plus 1 volt for each 50 W of total loop resistance.

Figure 1: Single-transmier loops Mulple-transmier loops

CAUTION: Use of a high-speed torque screw-

driver may damage the terminal blocks.

Loading...

Loading...