LUBRICATION

Maintain oil level in gear reducer at the check

level plug, located at rear drive. When required, refill

with SAE 85-140 Moly Fortified gear lube or Synthetic

SAE 70-90 gear lube.

Grease two (Model 225A has 3) bearings on the side

drive shaft and bearing at front end of this shaft annually.

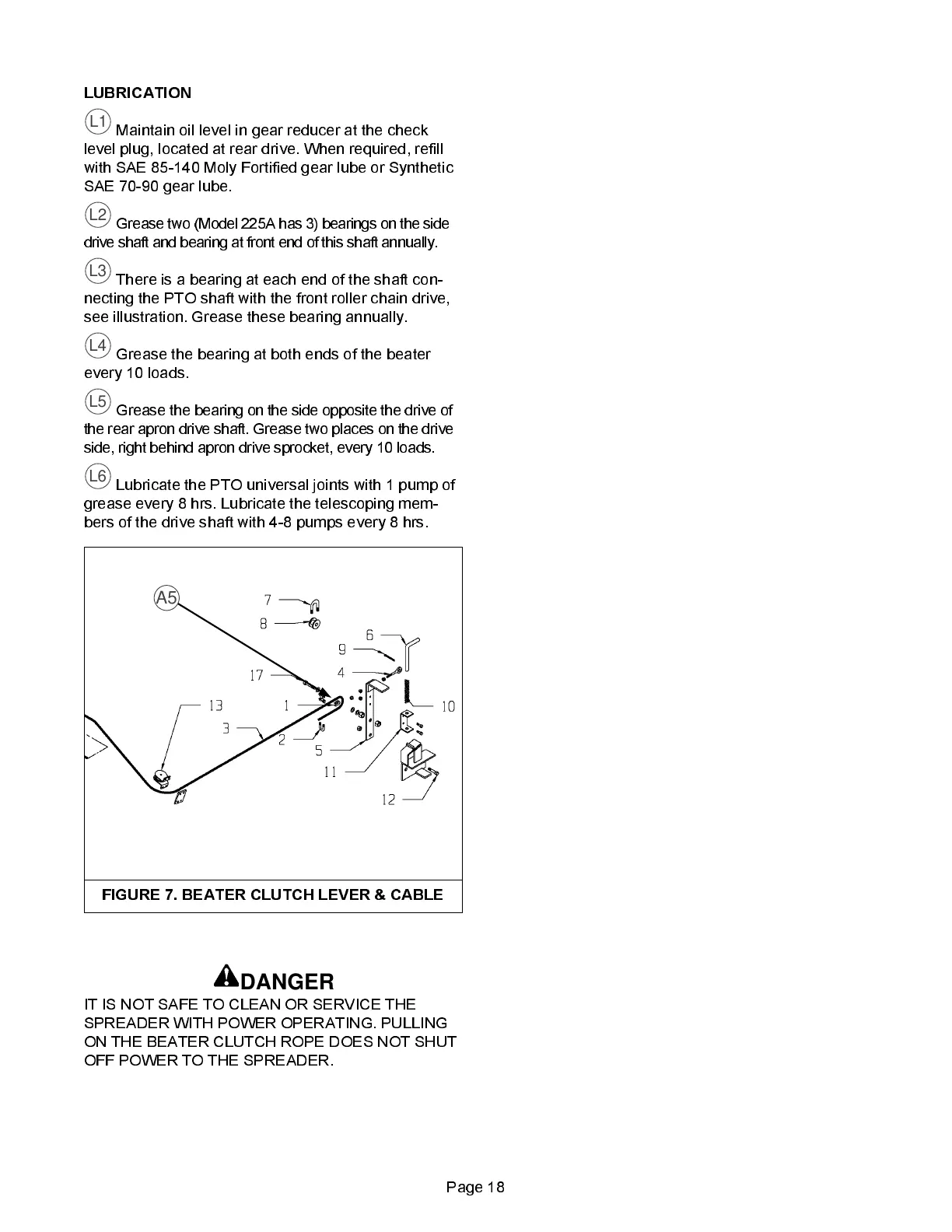

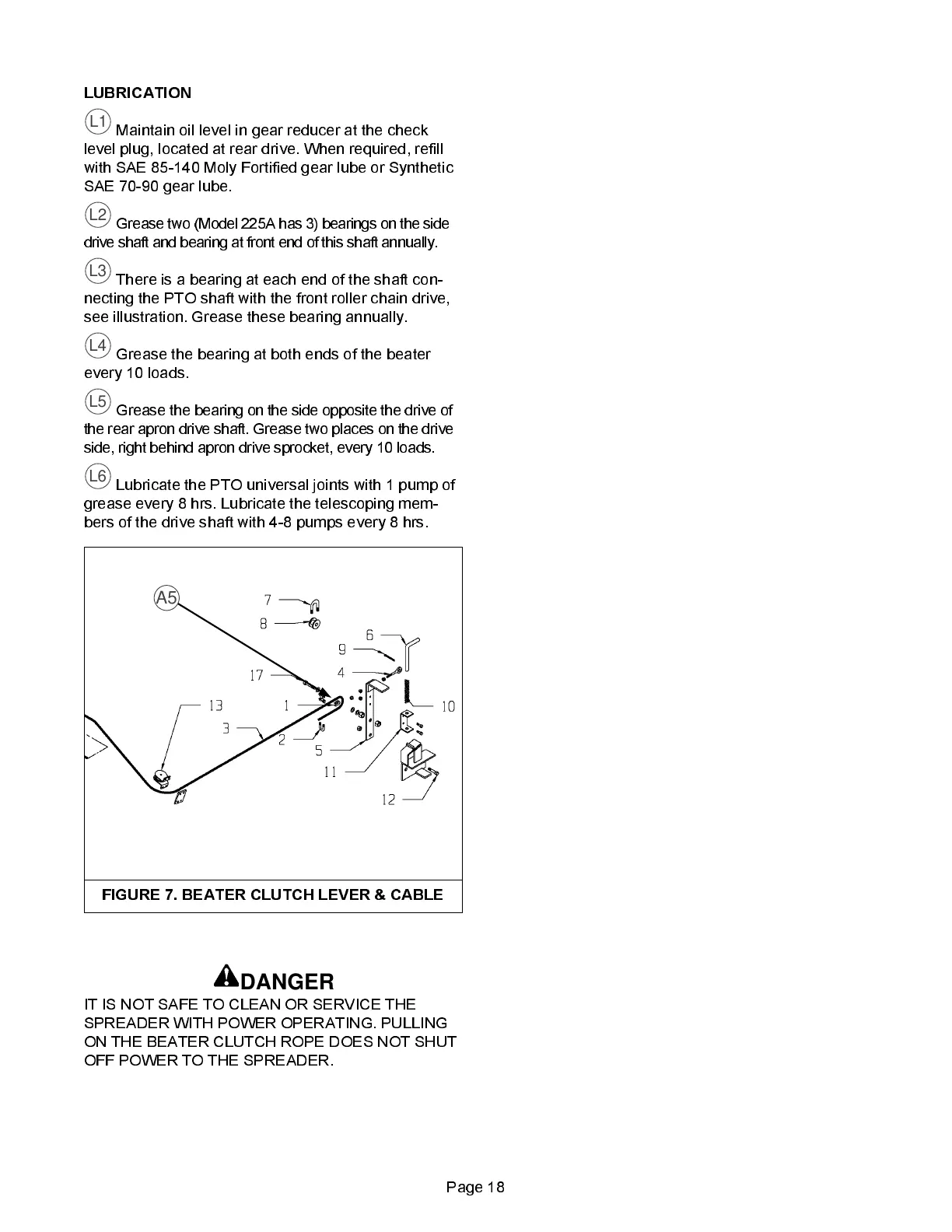

There is a bearing at each end of the shaft con-

necting the PTO shaft with the front roller chain drive,

see illustration. Grease these bearing annually.

Grease the bearing at both ends of the beater

every 10 loads.

Grease the bearing on the side opposite the drive of

the rear apron drive shaft. Grease two places on the drive

side, right behind apron drive sprocket, every 10 loads.

Lubricate the PTO universal joints with 1 pump of

grease every 8 hrs. Lubricate the telescoping mem-

bers of the drive shaft with 4-8 pumps every 8 hrs.

DANGER

IT IS NOT SAFE TO CLEAN OR SERVICE THE

SPREADER WITH POWER OPERATING. PULLING

ON THE BEATER CLUTCH ROPE DOES NOT SHUT

OFF POWER TO THE SPREADER.

Page 18

FIGURE 7. BEATER CLUTCH LEVER & CABLE

A5

L3

L4

L2

L5

L6

L1

Loading...

Loading...