9

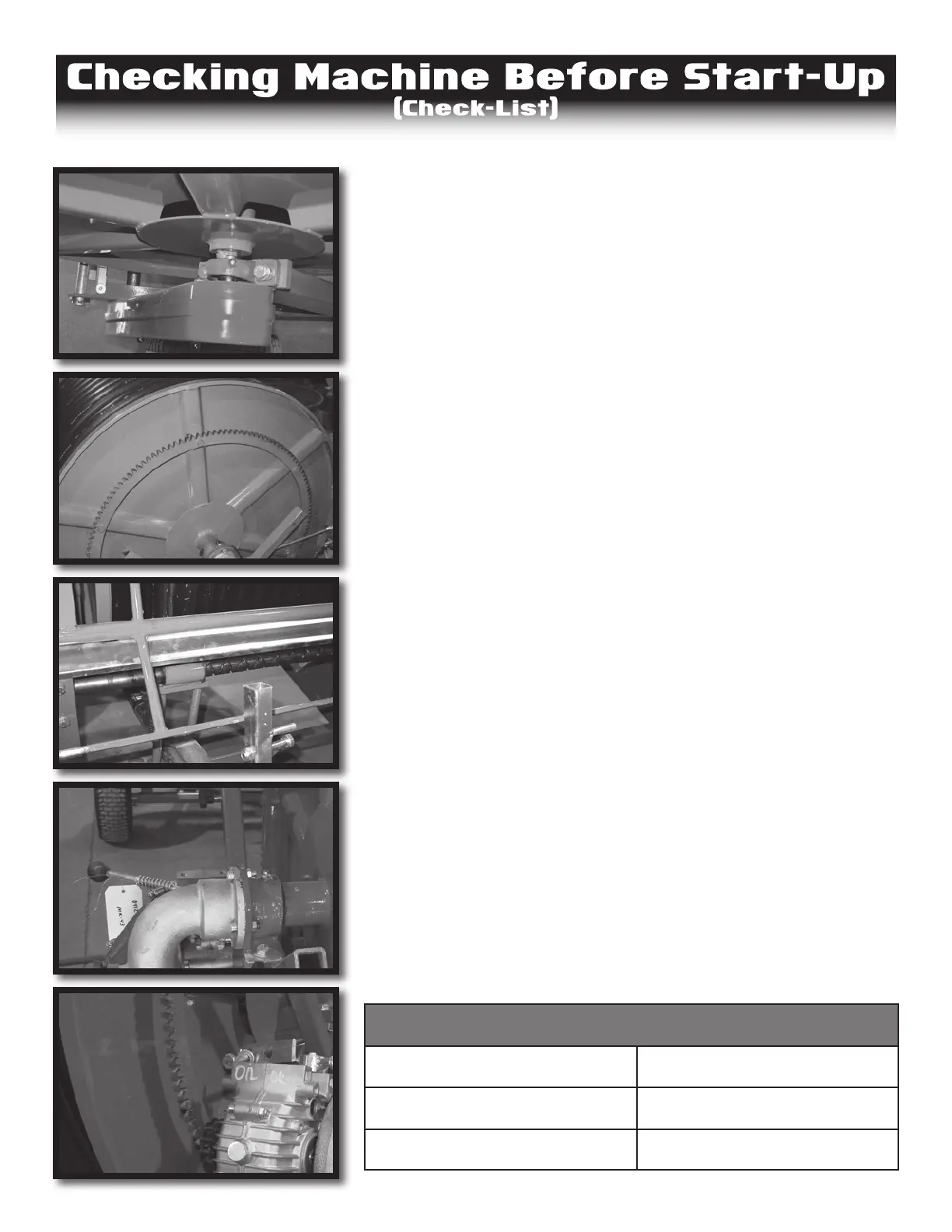

1. Check the oil level of the gearbox and if necessary add SAE

80W/90. Keep oil level at the side plugs in the gearbox in

order to bathe the shift fork in oil.

2. Grease the machine thoroughly (all grease ttings) and

thereafter, grease every 100 hours. Pay close attention

to the two grease ttings on the drum inlet. One grease

tting is located on the bottom side and lubricates the

drum inlet seals. Grease must be spread on the drum

gear teeth and at the drive shaft where the drum gear

and drive gear mesh. The scroll bar must also be kept

well greased, and the scroll knife must be lubricated

(grease tting) in order to function correctly.

3. Check the tire pressure and if necessary, inate to pressure

recommended on the tire (generally 35 PSI).

LUBRICANT TABLE

Gearbox SAE 80W/90

Reel Supports Grease NLGI No.2

Grease Fittings Grease NLGI No.2

Loading...

Loading...