Rotary Microtome HM 325

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf 387821 - English

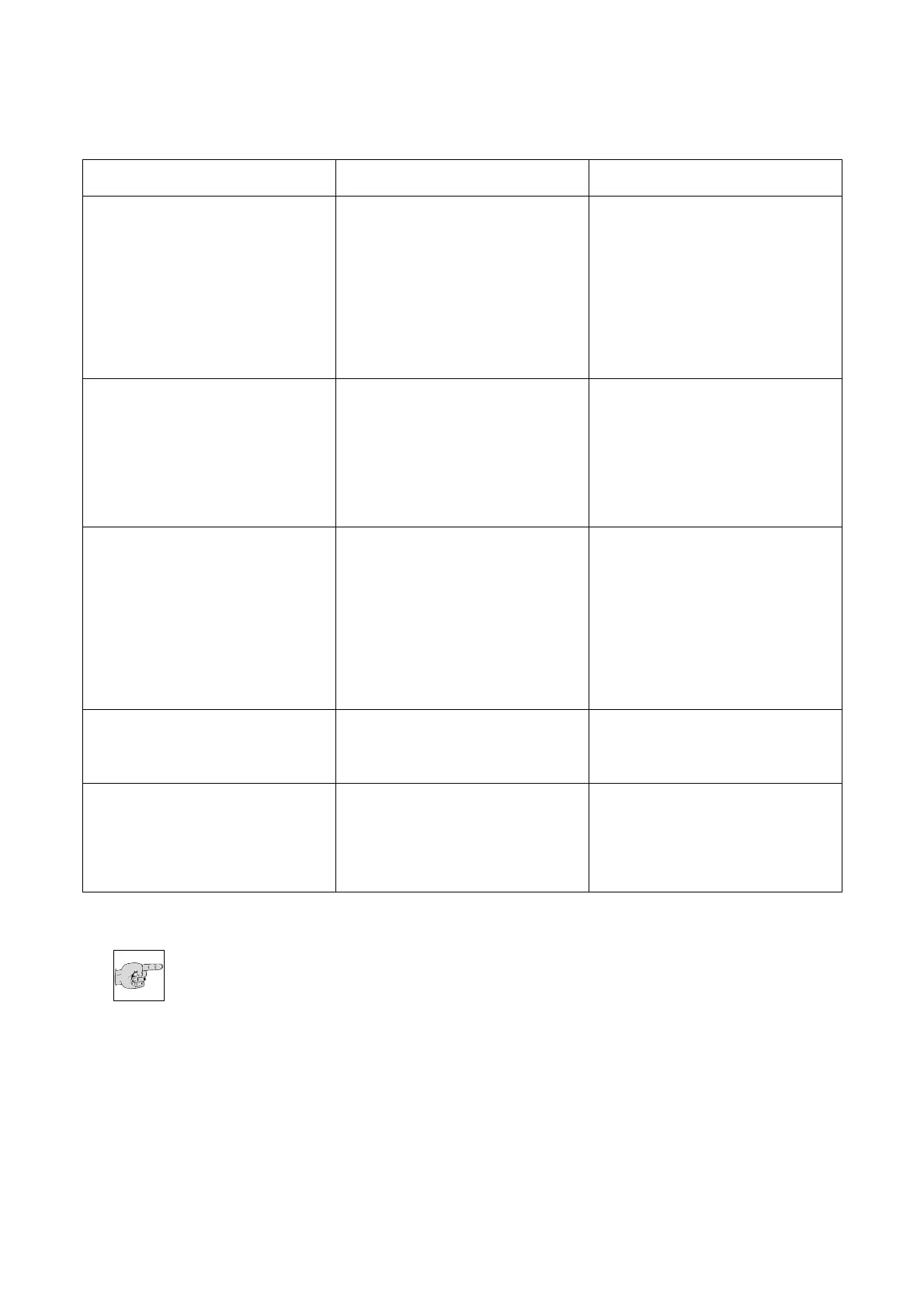

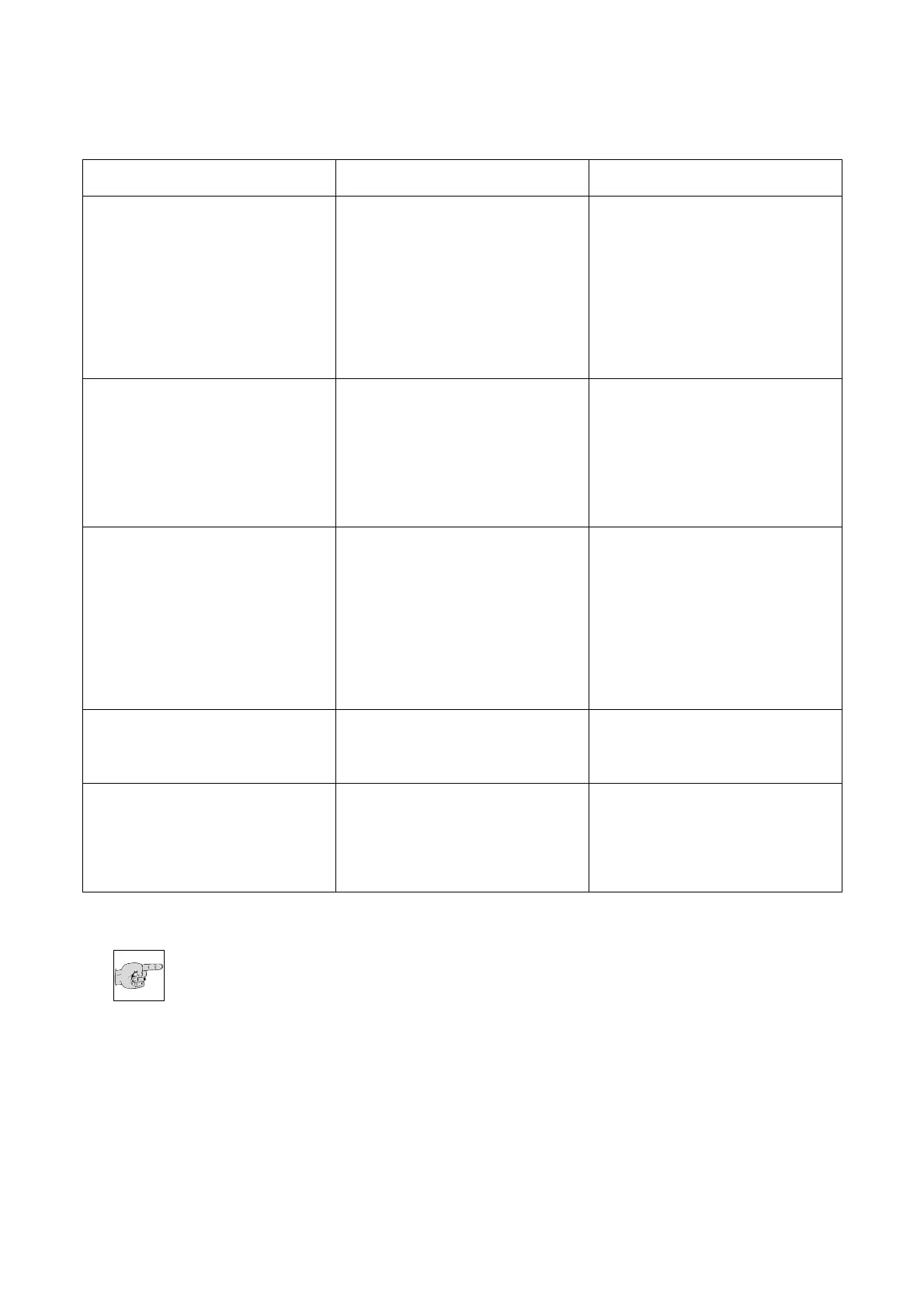

4-3 POSSIBLE SOURCES OF ERRORS – CAUSE AND REMOVAL

Problem

Cause Removal

Thick-thin-sections

− Blunt knife/blade.

− Knife angle, therefore,

unfavorable clearance angle.

− Insufficient clamping on

specimen clamping and/or

knife carrier.

− Move knife and/or insert a new

one.

− Try clearance angle

adjustments, until an optimal

angle can be found.

− Check all screw and clamping

connections on specimen

clamping and knife carrier.

Tighten them, if necessary.

Compressions

− Blunt knife/blade.

− Specimen too warm.

− Unfavorable clearance angle.

− Cutting speed too high.

− Move knife and/or insert a new

one.

− Cool specimen

− Try clearance angle

adjustments until an optimal

angle can be found.

− Turn handwheel slower.

"Chatter" on sections

− Cutting speed too high.

− Unfavourable clearance angle.

− Insufficient clamping on

specimen clamping and/or

knife carrier.

− Turn handwheel slower.

− Try clearance angle

adjustments until an optimal

angle can be found.

− Check all screw and clamping

connections on specimen

clamping and knife carrier.

Tighten them, if necessary.

No feed is carried out anymore,

and therefore, no sections are

produced.

− Front end position has been

reached.

− Coarse feed wheel is blocked.

− Move specimen backwards by

turning the coarse feed wheel.

− Remove blockade on coarse

feed wheel.

Tight handwheel

- partly

- during the entire movement

− Debris and section waste

between microtome and base

plate.

− Dirty link block.

− Remove section waste and

clean microtome.

− Contact a service technician.

Note:

In case of malfunctions and/or service work, please turn off the instrument and contact your

local dealer.

Loading...

Loading...