Installation of the Connecting Pipe MCAC-UTSM-2009-03

46 Installation

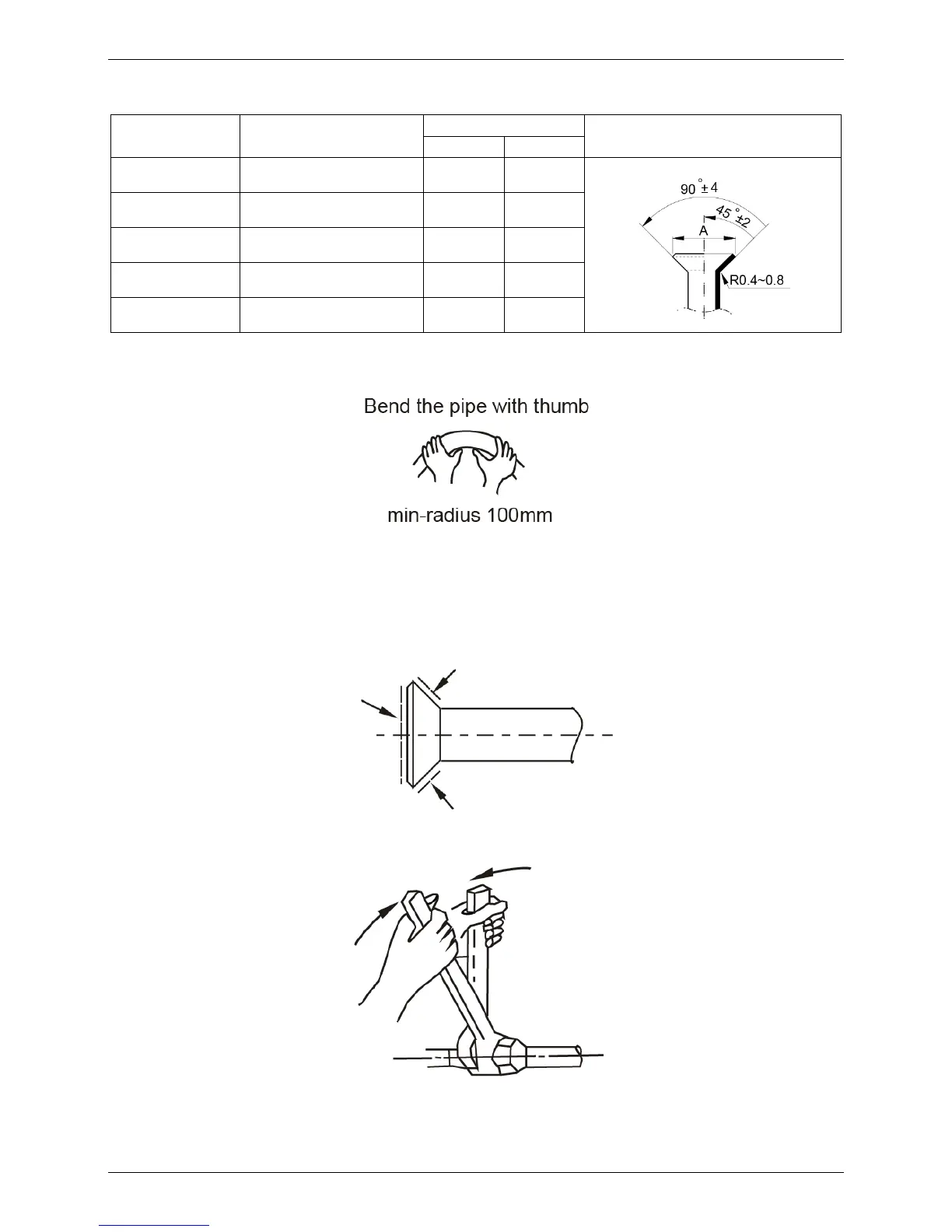

Insert a flare nut into a pipe and flare the pipe.

Refer to the following table for the dimension of flare nut spaces.

Pipe gauge Tightening torque

Flare dimension (A)

Flare shape

Min Max

Φ6.4

15

~16N.m

(153

~163kgf.cm)

8.3 8.7

Φ9.5

25

~26N.m

(255

~265 kgf.cm)

12.0 12.4

Φ12.7

35

~36 N.m

(357

~367 kgf.cm)

15.4 15.8

Φ15.9

45

~47 N.m

(459

~480 kgf.cm)

18.6 19.0

Φ19.1

65

~67 N.m

(663

~684 kgf.cm)

22.9 23.3

2. Connect the indoor unit at first, then the outdoor unit.

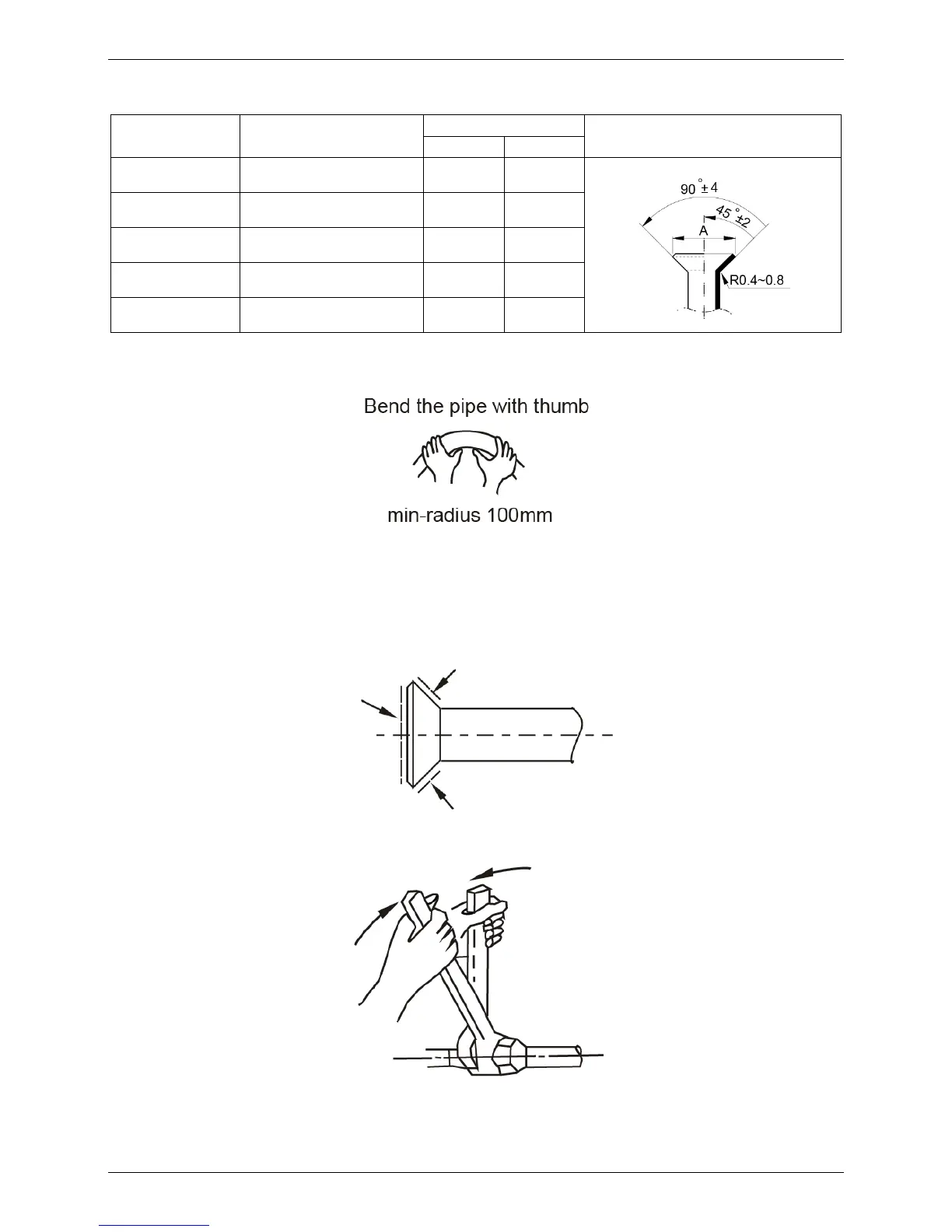

z Bend the tubing in proper way. Do not harm to them.

z The bending angle should not exceed 90°.

z Bending position is preferably in the middle of the bendable pipe. The larger the bending radius the

better it is.

z Do not bend the pipe more than three times.

z When connecting the flare nut, coat the flare both inside and outside with either oil or ester oil and

initially tighten by hand 3 or 4 turns before tighting firmly.

z Be sure to use both spanner and torque wrench together when connecting or disconnecting pipes to the unit.

Caution:

z Too large torque will harm the bell mouthing and too small will cause leakage.

z After the connecting work is finished, be sure to check that there is no gas leak.

Loading...

Loading...