MCAC-2008-11 Air-cooled Modular Chiller

37

12.2 Water System Installation

Every pipeline’s joint has outlet and inlet mark. Please notice when connecting pipelines:

Because the plate heat-exchanger has been used, the space for water passing is narrow, so it is easy

to be jammed by particulate, which may cause harmful freezing and damage the system. So it is

strongly recommended to install a 20-item mesh net Y-shaped filter close to module-side chilled-water

inlet (or cooling water) as much as possible.

Before connecting the water system to unit, it is necessary to clean the whole water pipeline and

replace a new filter net, after ensuring that the water pipeline is clean, the connection can be done.

The soft connector should be used between the inlet (outlet) water pipeline and the unit to avoid

vibration.

Turn on the water pump before unit starting, the water-flow switch should be installed on the water inlet

pipeline before unit and connect pump’s wire to main module’s W1, W2 terminals.

Water-discharge switch must be installed on the outlet pipeline and the gas discharge valve on the inlet

pipeline, the hand of the discharge switch must be taken away to prevent water shortage caused by

wrong hand operation when unit is running.

The chilled-water pipeline should be covered with adequate heat insulated material to keep the Temp.

of the water and prevent dewing.

In winter, if the unit is shut down, the water in the plate heat-exchanger and pipeline may freeze. To

prevent freezing, it is absolutely forbidden to shut down the system (the system has the anti-freeze

function) .If there is still be frozen, all the water in the system should be drained away, if it is difficult to

drain the water, it is recommended to use some anti-freeze mixture such as glycol or propylene glycol.

Note:

It is absolutely forbidden to use salt mixture, because it would corrode the system and cause damage.

There is no scale problem when using industrial standard water as chilled-water, on other hand, if the

water from well or river is used, it may form much scale and sand. So it is necessary to pre-filter the

water and intenerate by using relevant equipment before it enters the chilled-water system. If there is

sand or mud in the evaporator, it will be blocked and cause freezing .So it is important to test the water’s

PH value, conductivity, chlorine hydronium, sulfur hydronium etc. before used.

Note:

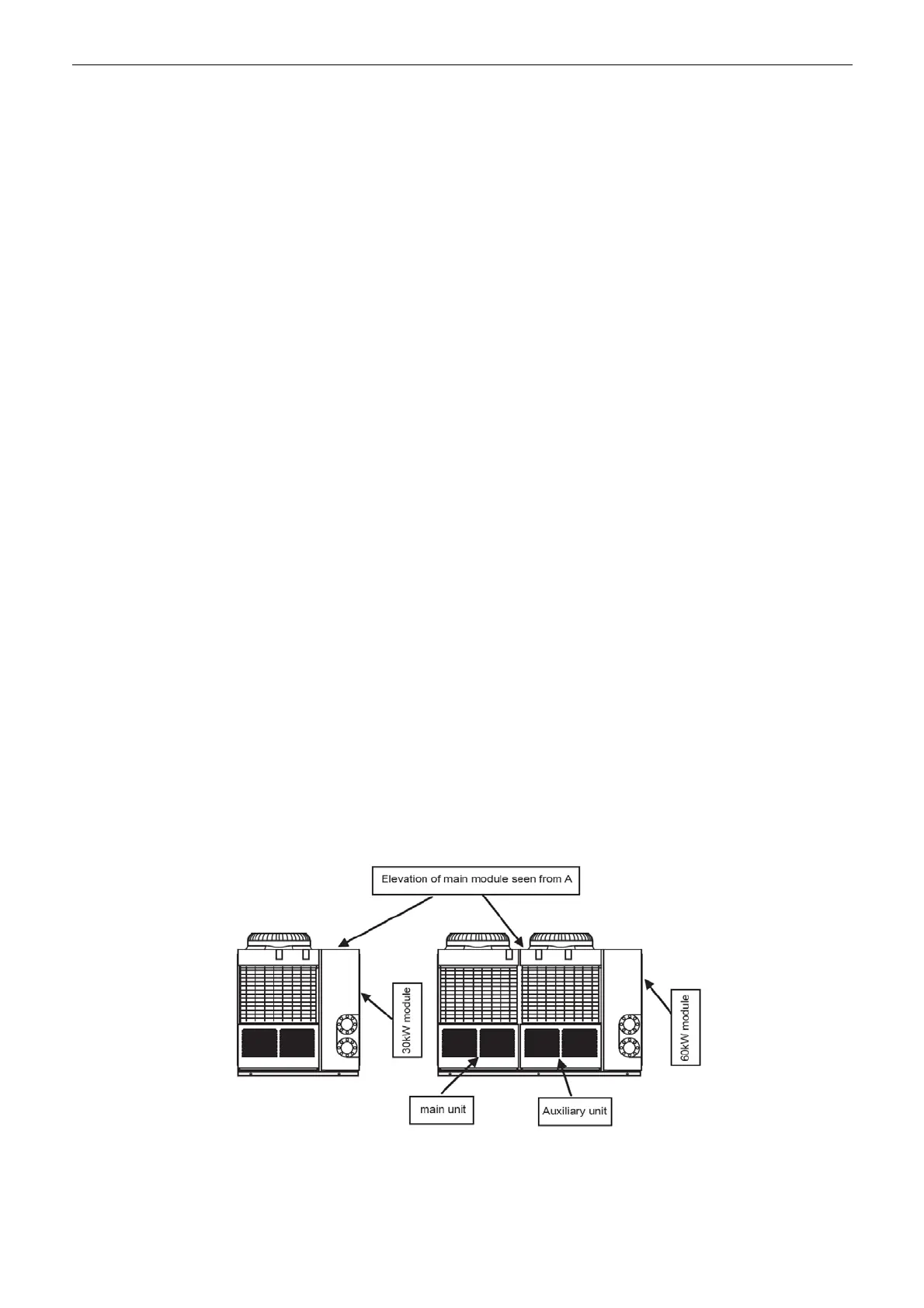

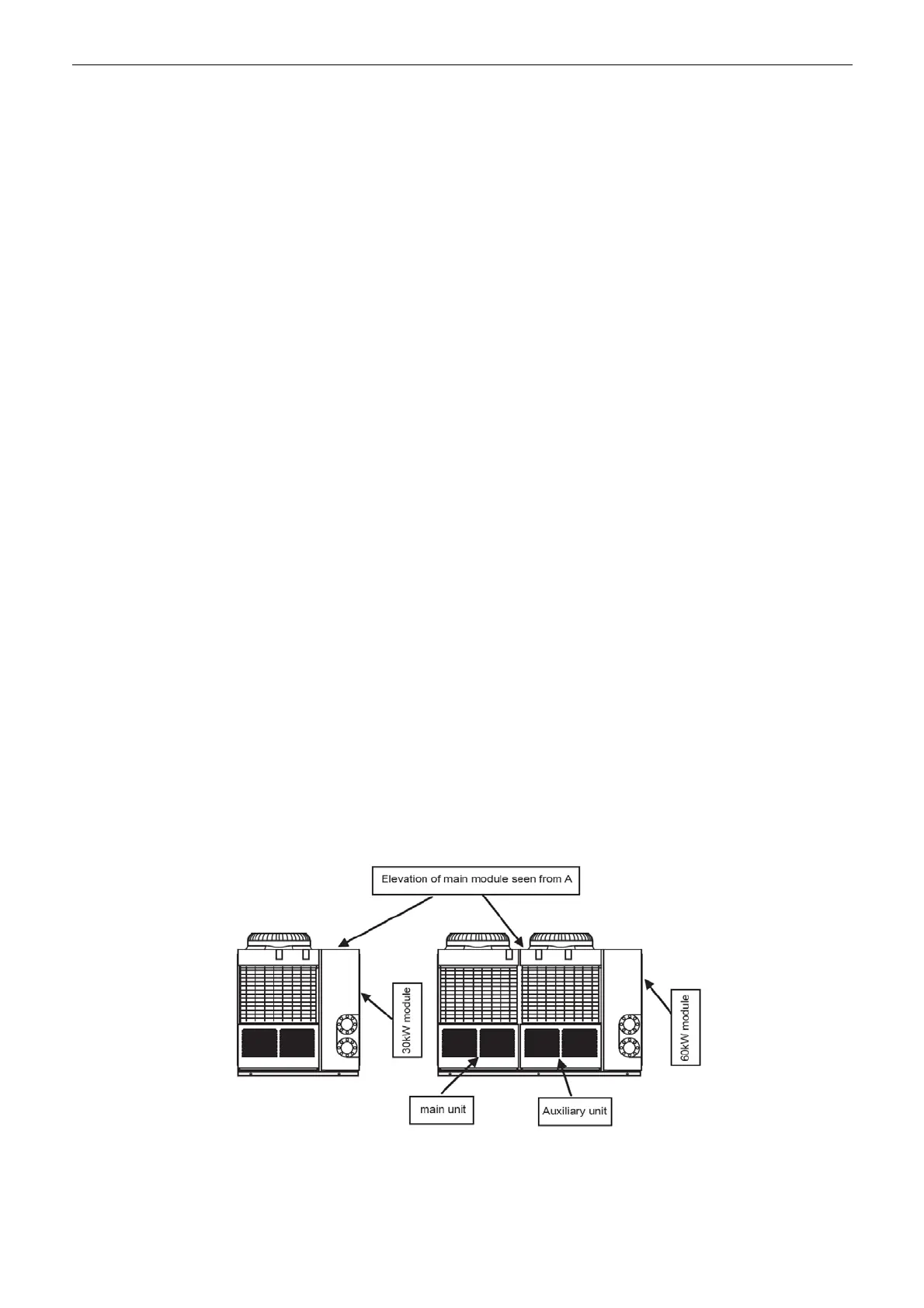

For 30kW module ,each module consists of two units (two systems).They are system A,system B respectively from water-pipe

side; For 65kW module, each module consists of two units (four systems) and they are system A, system B (for main unit),

system A, system B (for auxiliary unit) respectively from water-pipe side.

Loading...

Loading...