MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

84

2. It is recommended to use the smallest liquid line size permitted to minimize system

charge which will maximize compressor reliability.

3. The above table may be used for sizing horizontal runs.

4. Do not exceed 45.72m maximum vertical separation.

It is suggested to install oil return bend per ten meter.

Indoor unit pipe connection:

Keep the coil connections sealed until refrigerant connections are made.

Indoor coil is shipped with No charge. Evacuate the system before charging with refrigerant.

Install refrigerant tubing so that it does not block service access to the front of the unit.

Nitrogen should flow through the refrigerant lines while brazing.

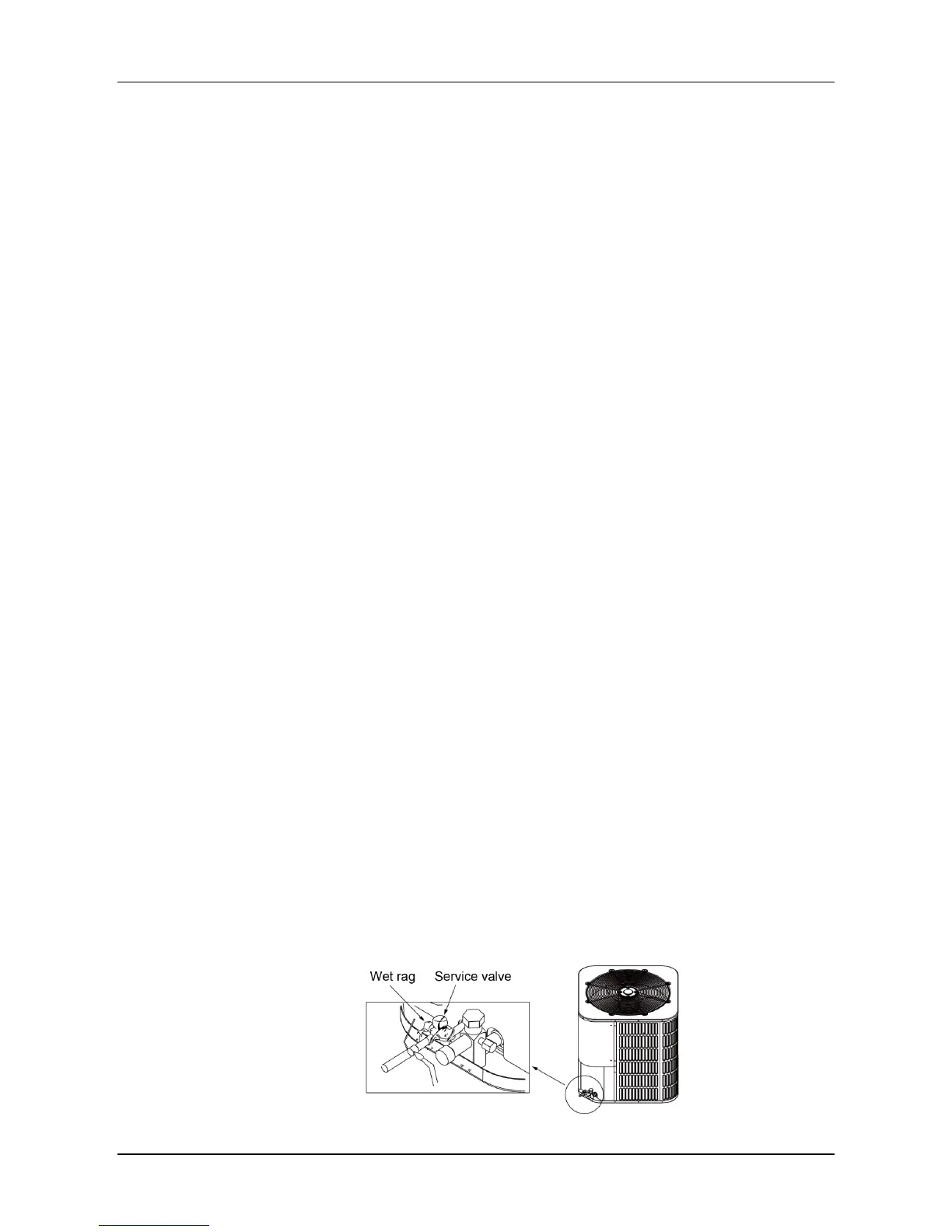

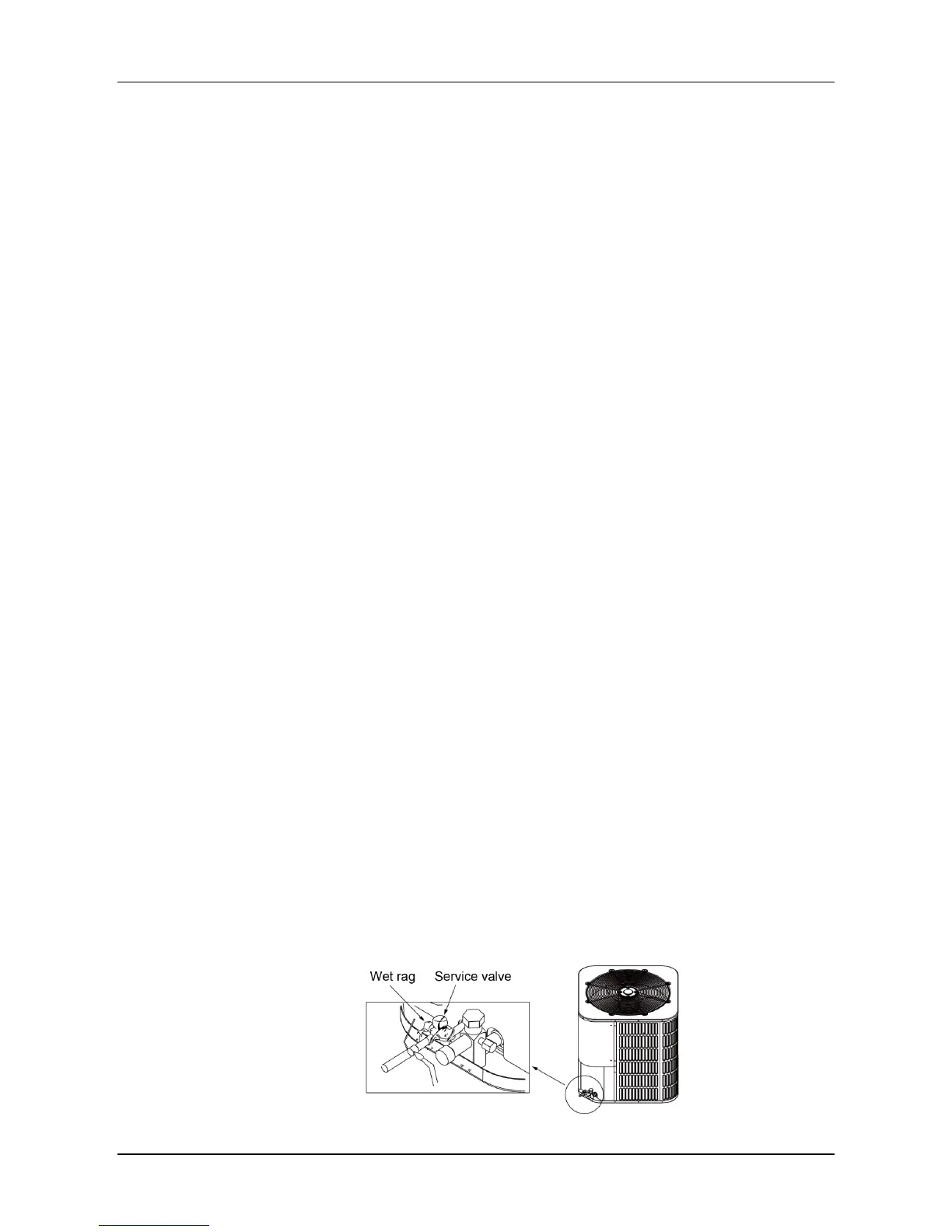

Use a brazing shield to protect the cabinet’s paint and a wet rag to protect the rubber

grommet from being damaged by torch flames.

After the refrigerant connections are made, seal the gap around the connections with

pressure sensitive gasket.

Be sure to cover all the exposed parts of the flare pipe joints and refrigerant pipe on the

liquid-side and the gas-side with insulating materials. Ensure that there is no gap between

them. Incomplete insulation may cause water condensation.

For MTA-18WN1, after connecting two pipes with copper nuts which are packed in indoor

unit accessory to indoor unit, another pipe packed in indoor unit accessory should be

welded with the gas connecting pipe of indoor unit.

Outdoor unit pipe connection:

Notes: Never attempt to repair any brazed connections while the system is under pressure.

Personal injury could result.

Remove the cap and Schrader core from both the liquid and suction service valve service

ports at the outdoor unit. Connect low pressure nitrogen to the liquid line service port.

Loading...

Loading...