R410A All DC Inverter V5 X Series 50Hz MCAC-VTSM-2015-10

98 Installation

4. Refrigerant pipe installation

4.1 Basic requirements

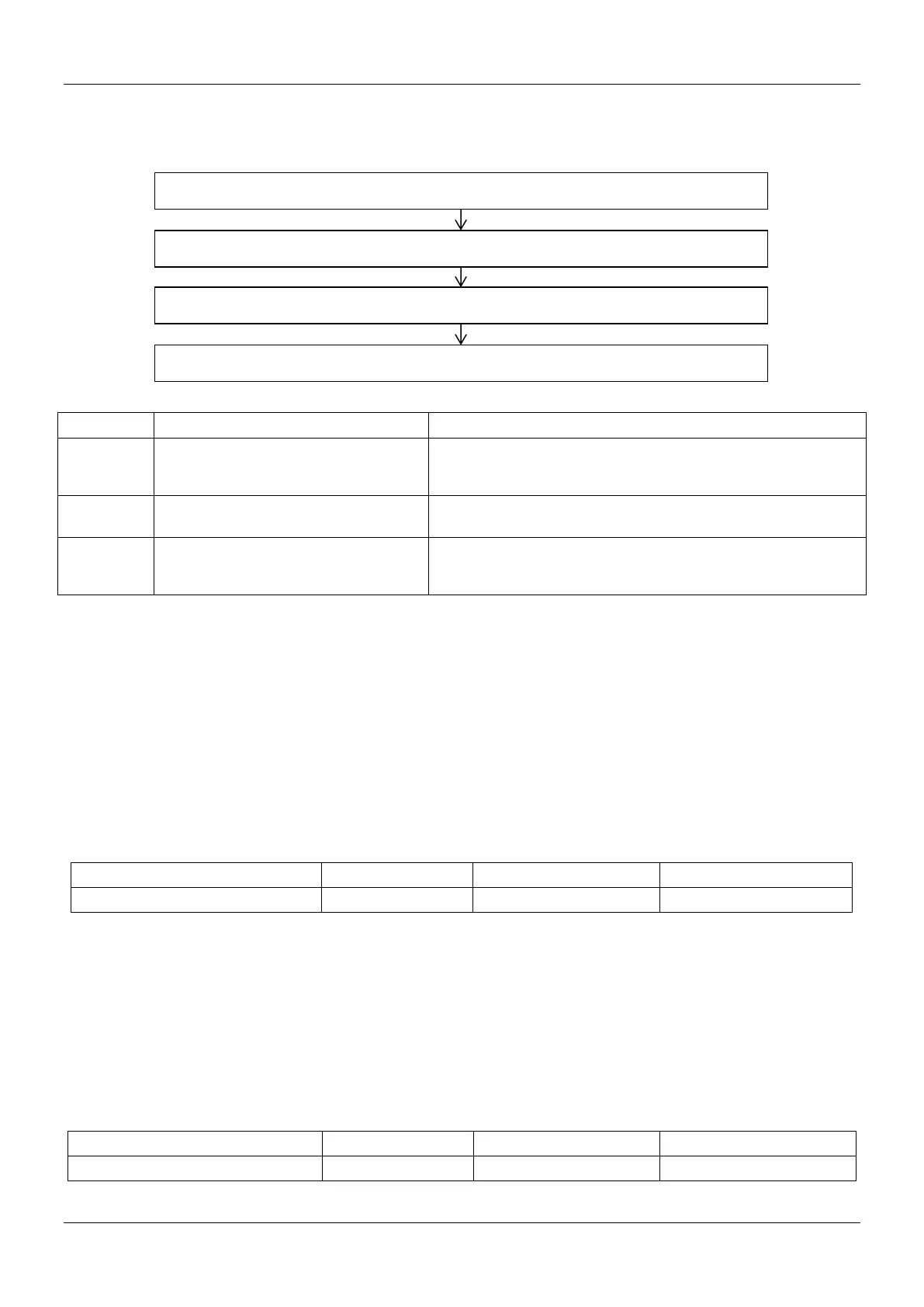

4.1.1 Operation procedure

4.1.2 Three principles for refrigerant piping

Rainwater/Engineered water /

Condensation may enter the piping

system

The process of tubing must follow standard procedures → Blow

cleanly → Vacuum

Oxidation produced by welding/Outside

dust /Sundries

Charge nitrogen gas to prevent oxidation when welding/Attention the

cleanness during the piping process → Blow clean

Imprecision welding/Unqualified airproof

to bell-mouth/Leakage of the fringe

Use suitable welding rod to weld/Comply with welding operation

criteria/Comply with bell-mouth connecting operation criteria/Comply

with the interface operation criteria →Air seal test

Caution: Removing oil from copper pipe of a system that uses R410A

For the system that uses R410A, oil-free copper pipes should be selected (they can also be customized). If ordinary (oily) copper

pipes are used, it must be cleaned with gauze that is dipped into tetrachloroethylene solution.

Purpose of cleaning copper pipe: Remove the lubrication (industrial oil used during the processing of the copper pipe) attached to

the inner wall of the copper pipe. The ingredients of such lubricants are different from those of the lubricants used by the R410A

refrigerant, and will leave deposits in the system, which may cause complex system errors.

Special Note: Never use CCl4 for pipe cleansing and flushing, or the system will be seriously damaged.

4.1.3 Support for refrigerant pipe

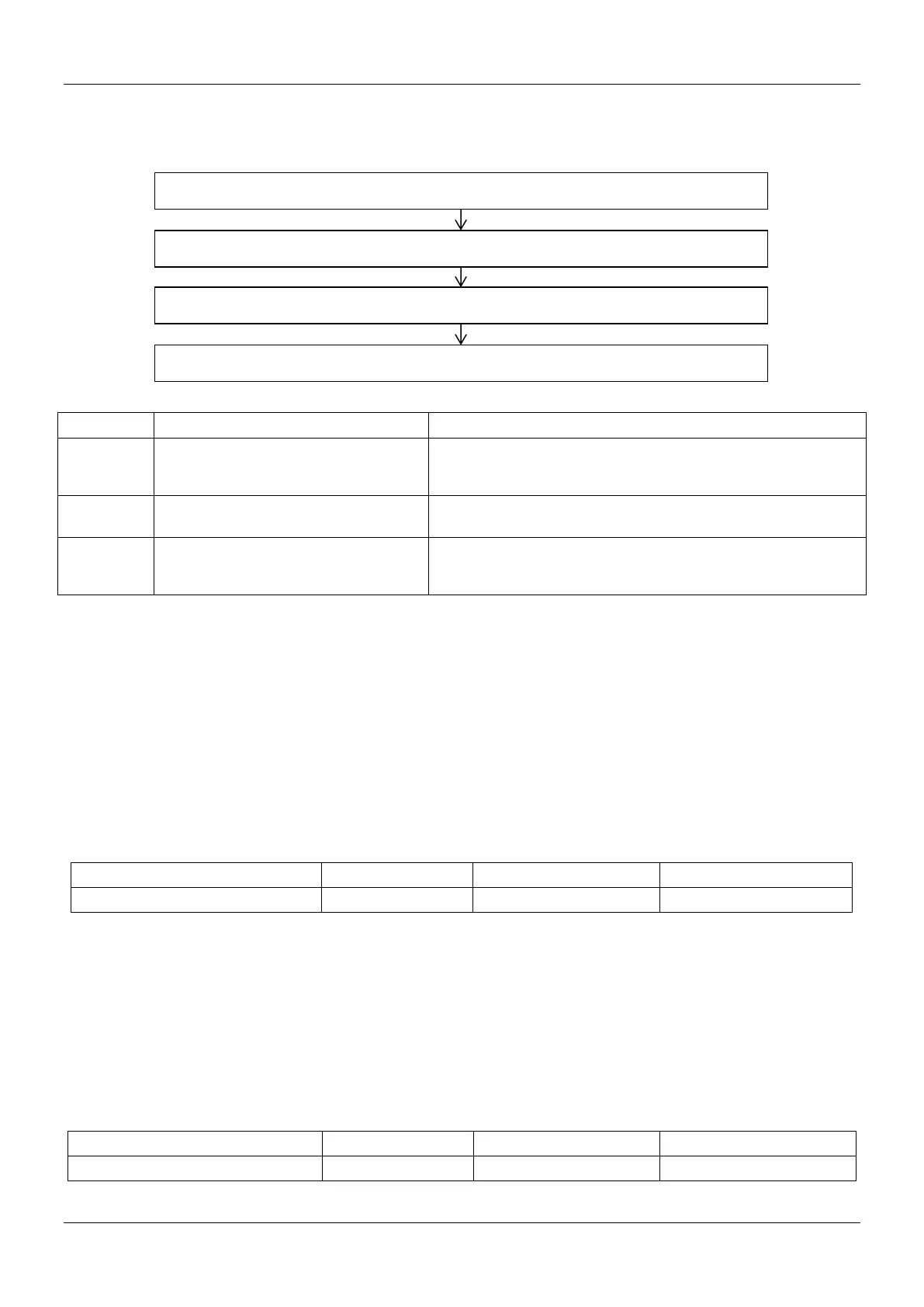

1. Fixing horizontal pipe

When the air conditioner is running, the refrigerant pipe will deform (for example, shrunk/expanded or droop).

To avoid pipe damage, use hangers or supports (see the table below for the criteria).

Interval between support points (m)

In general, gas pipe and liquid pipe should be suspended in parallel, and the interval between support points

should be selected according to the diameter of the gas pipe. The temperature of the flowing refrigerant will

change according to operation and working conditions, which will result in expansion and shrinkage of the

refrigerant piping, therefore piping with thermal insulation should not be clamped tightly, in order to avoid any

rupturing of the copper piping as a result of unnecessary stress.

2. Fixing vertical piping

Fix the pipe along the wall according to the pipeline route. Round log should be used at the pipe clip to replace

thermal insulation material, “U”-shape pipe should be fixed outside the round log, and the round log should be

provided with anticorrosion treatment.

Interval between support points (m)

Determine the route and size of the pipeline according to the construction drawing

Make and install brackets, hangers and supports

Make and arrange pipe accessories → Recharge nitrogen gas for protection

Welding → Pipe flushing → Air seal test → Thermal insulation → Vacuum

Loading...

Loading...