R410A All DC Inverter V5 X Series 50Hz MCAC-VTSM-2015-10

112 Installation

more than 300mm, it is 3mm. The permitted deviation of pipe end flatness is 2mm.

Discrepancy between two diagonal lines of rectangle duct shall not be more than 3mm. Discrepancy between

two diameters of any cross-cut circular flange shall not be more than 2mm.

6.2 Duct connection

1. Duct connection

1) The seam of duct board splice should be stagger and cross-seam is not allowed.

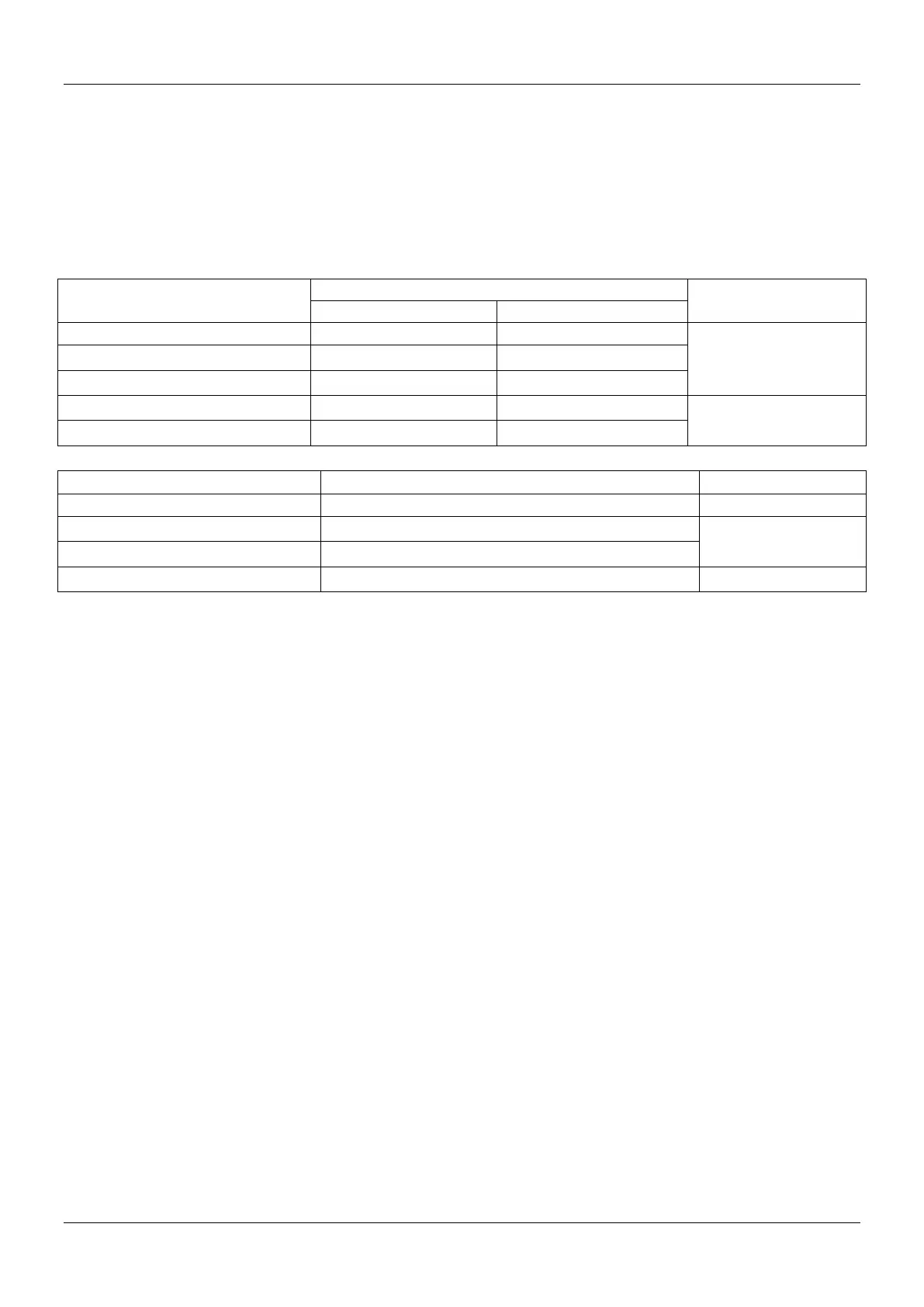

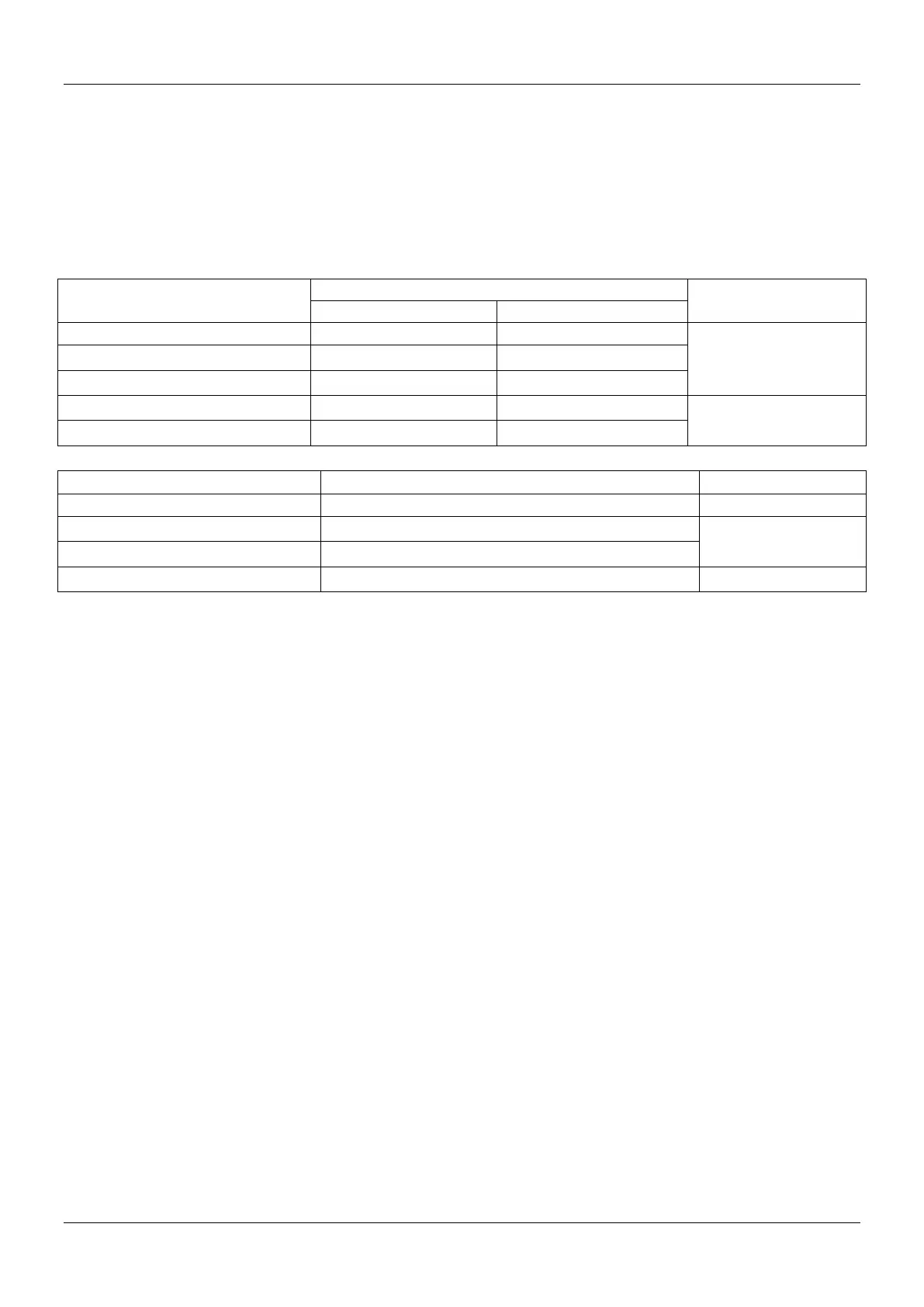

2) Specifications of metal duct flanges shall not be less than the data as shown in the table below.

Specification to flange and bolt of circular metal duct

Specification of flange (mm)

Specifications to flanges and bolts of rectangle metal duct (mm)

Dimension of long edge of duct(b) (mm)

Specification of flange(angle steel) (mm)

3) Diameter of bolt and rivet to duct flange for middle/low pressure system should be no more than 150mm.

High pressure system ducts should be no more than 100mm.

4) Four sides of rectangle duct flanges should be designed with screw hole.

5) If using reinforcement methods for duct flanges the corresponding specifications may be extended.

2. Connection of nonmetallic duct

Specifications of flanges should be in accordance with standard, gap of bolt hole should be no more than

120m. Four sides of rectangle duct flanges should be designed with screw hole.

3. Strengthening of metal duct

When edge length of rectangle duct is more than 630mm, edge length of insulation duct is more than 800mm

and length of pipe section is more than 1250mm, or single-edge level area of low pressure duct is more than

1.2 square meters and single-edge level area of high/middle pressure duct is more than 1.0 square meter,

strengthening measures should be taken.

4. Strengthening of nonmetallic duct

When diameter or edge length of HPVC duct is more than 500mm, the joint section of duct and flange should

be equipped with strengthening board and the gap should not be more than 450mm.

6.3 Main points for duct connections

1. Supporting, hanging and mounting brackets should be made of angle iron. Position of expansion bolt should

be correct, firm and reliable. The buried part could not be painted. Spacing should be in accordance with

regulations below:

1) If duct is installed horizontally, spacing should be no more than 4m when diameter or edge length is less

than or equal to 400mm, while spacing should be no more than 3m when diameter or edge length is more than

400mm.

2) If duct is installed vertically, spacing should be no more than 4m and ensure there is at least 2 fixed points

on each straight pipe.

2. Supporting, hanging and mounting brackets cannot be installed at air vent, valves, checking door and

automatically controlled device, and distance to air opening or plugged tube shall not be less than 200mm.

Loading...

Loading...