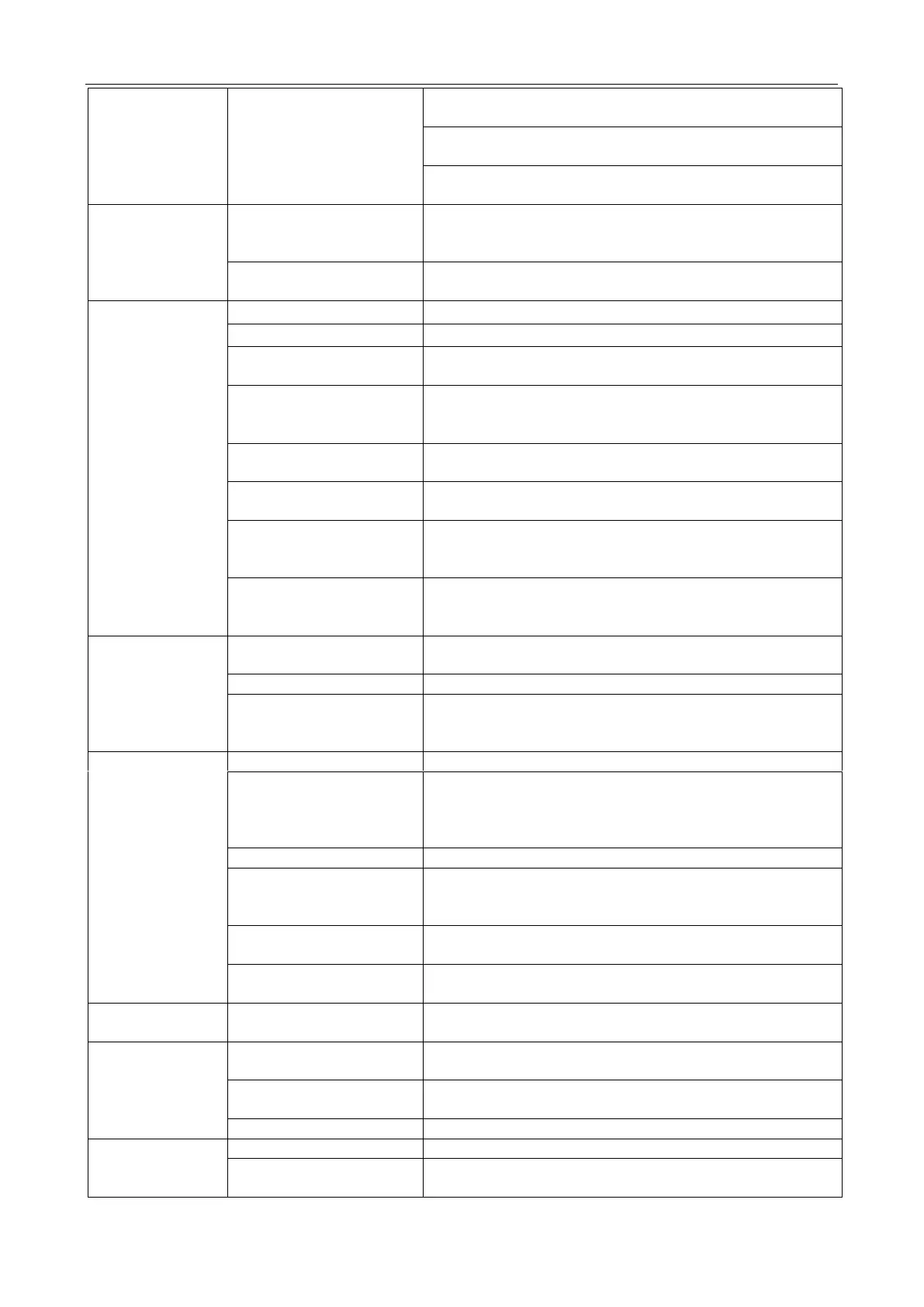

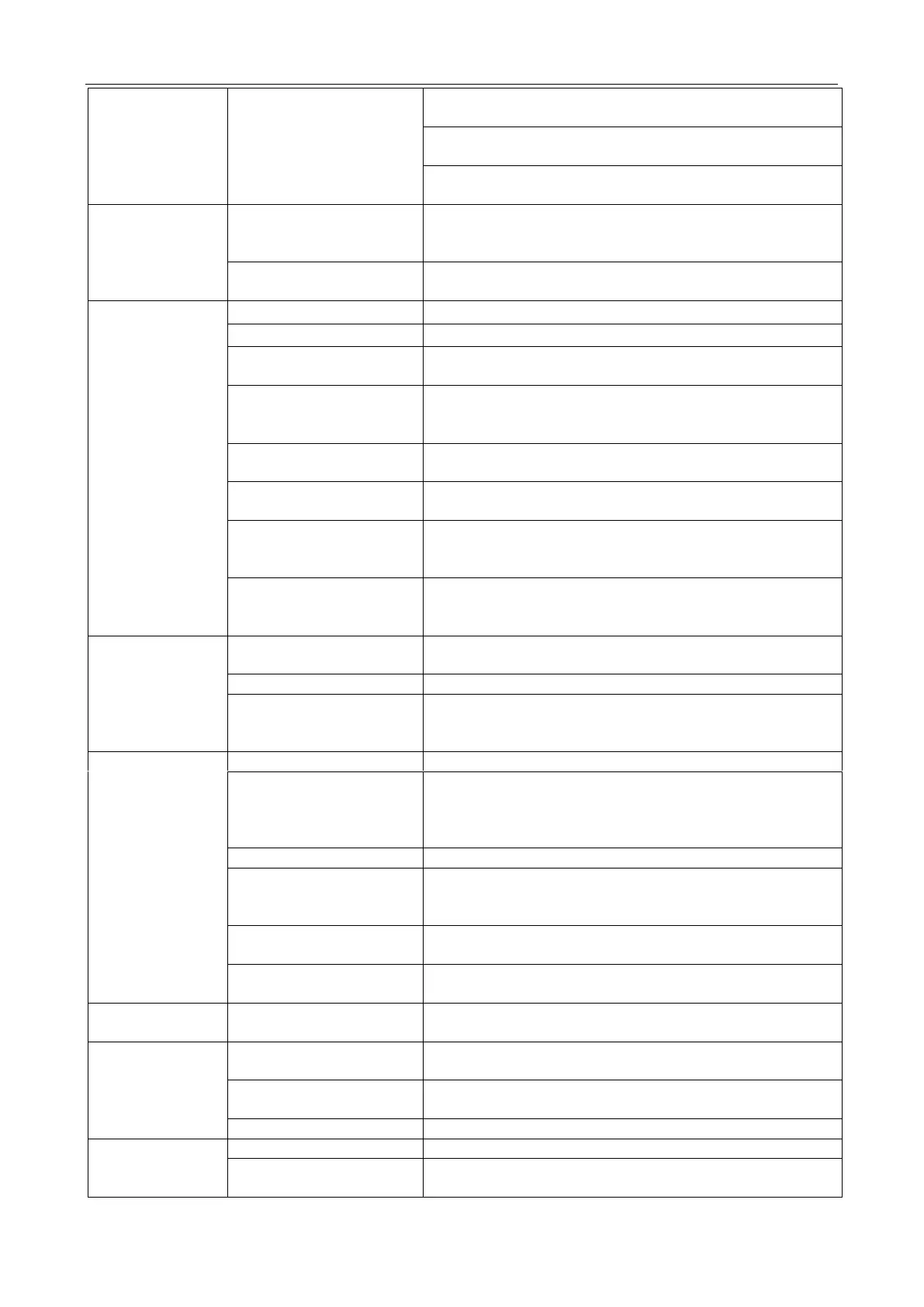

18

Test capacitor.

Replace if not within +/-10% of manufacture's rating.

Check bearings. Replace the motor if the blower wheel cannot

rotate freely.

Pay attention to any change from high speed to low speed.

Replace the motor if the speed does not change.

Compressor stops

instantly after

startup.

The amount of the refrigerant is too much, making the

compressor load too big. Recycle and recharge the refrigerant

after checking for the reason.

The compressor is blocked inside. Replace after checking for

the reason.

Check voltage at electrical outlet. Correct if none.

Check and correct if water alarm happens.

Check voltage at the power cord terminal on Main PCB.

Replace the power cord if none.

Transformer (Discharge

transformer before testing)

Check resistance between the two input/output lines on

transformer. Replace the transformer if either of the

input/output is open or the transformer is damaged.

Wire disconnected or

connection loose

Connect wire. Refer to wiring diagram for terminal

identification. Repair or replace loose terminal.

Select fan speed and Check the voltage on main PCB. Replace

the main PCB if no voltage in anyone.

Capacitor (Discharge

capacitor before testing)

Test capacitor.

Replace if not within +/-10% of manufacture's rating. Replace if

shorted, open or damaged.

Fan blower hitting scroll. Realign assembly.

Check fan motor bearings. Replace the motor if motor shaft do

not rotate.

Replace the fan blower if cracked, out of balance, or partially

missing.

Replace the motor if knocking sounds continue when running

or loose, or the motor hums or noise appears to be internal

while running.

Compressor will

not run while fan

motor runs.

Check voltage. Call Supply Authority if not within limits.

Check the wire connections, if loose, repair or replace the

terminal. If wires are off, refer to wiring diagram for

identification, and replace. Check wire locations. If not per

wiring diagram, correct.

Check voltage of main PCB. Replace the main PCB if open.

Capacitor (Discharge

capacitor before testing)

Check the capacitor.

Replace if not within +/-10% of manufacturers rating. Replace

if shorted, open, or damaged.

Check the temperature setting if not at the coolest (in cooling

mode) or the warmest (in heating mode). Set it if not.

Check the compressor for open circuit or ground. If open or

grounded, replace the compressor.

Remove the cabinet and carefully rearrange tubing not to

contact cabinet, compressor, shroud and barrier.

Water depth is over load in

chassis(P1)

Use a drain hose and a pan to drain the condensed water in the

chassis.

Water depth sensor if

failure

Check and replace if failure.

shaded pole motor failure

Check and replace if the motor is failure.

Cooling or heating

feels not good

Clean or replace if restricted.

Realign and assemble if the installation of the air discharging

pipe failure. Replace if damaged.

Loading...

Loading...