OM-1593 Page 15

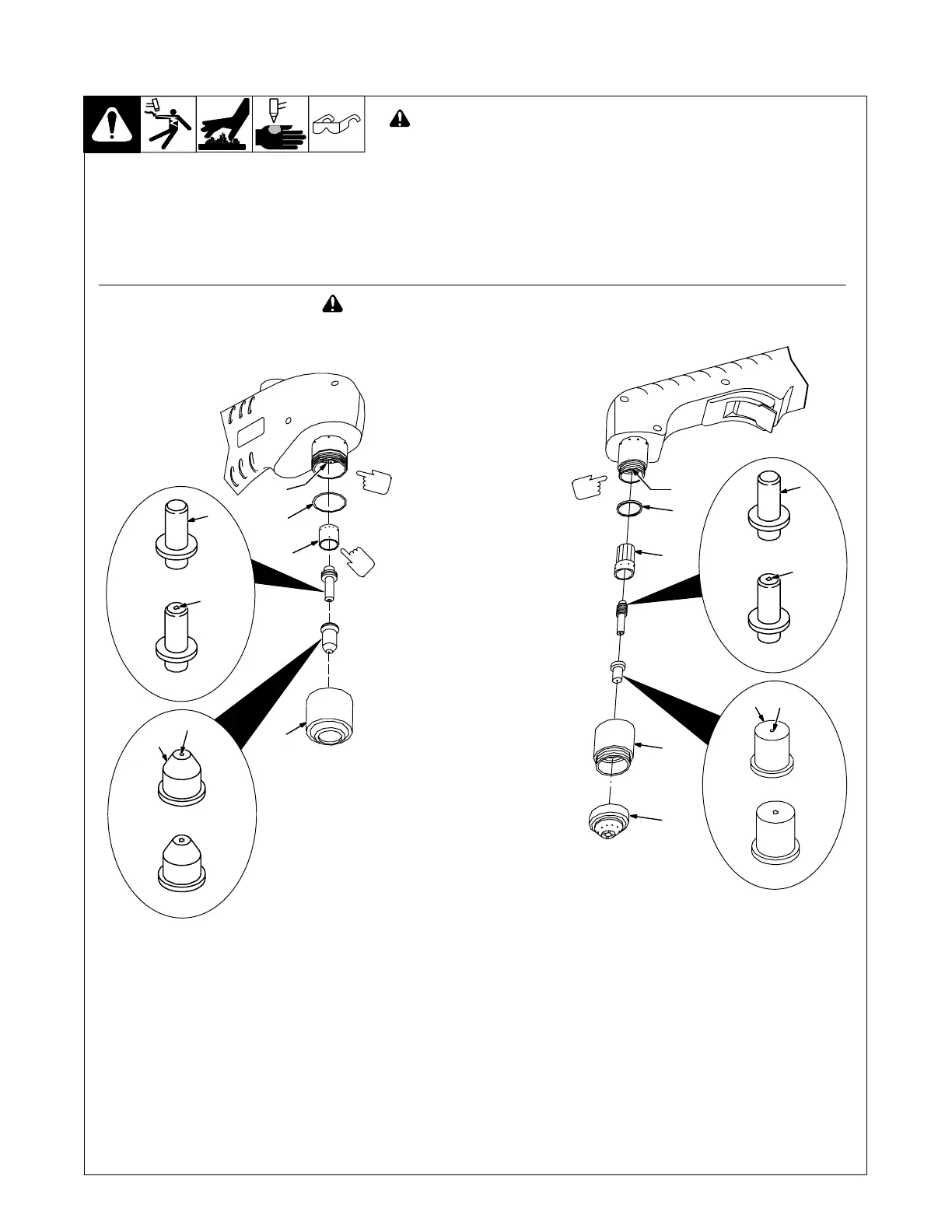

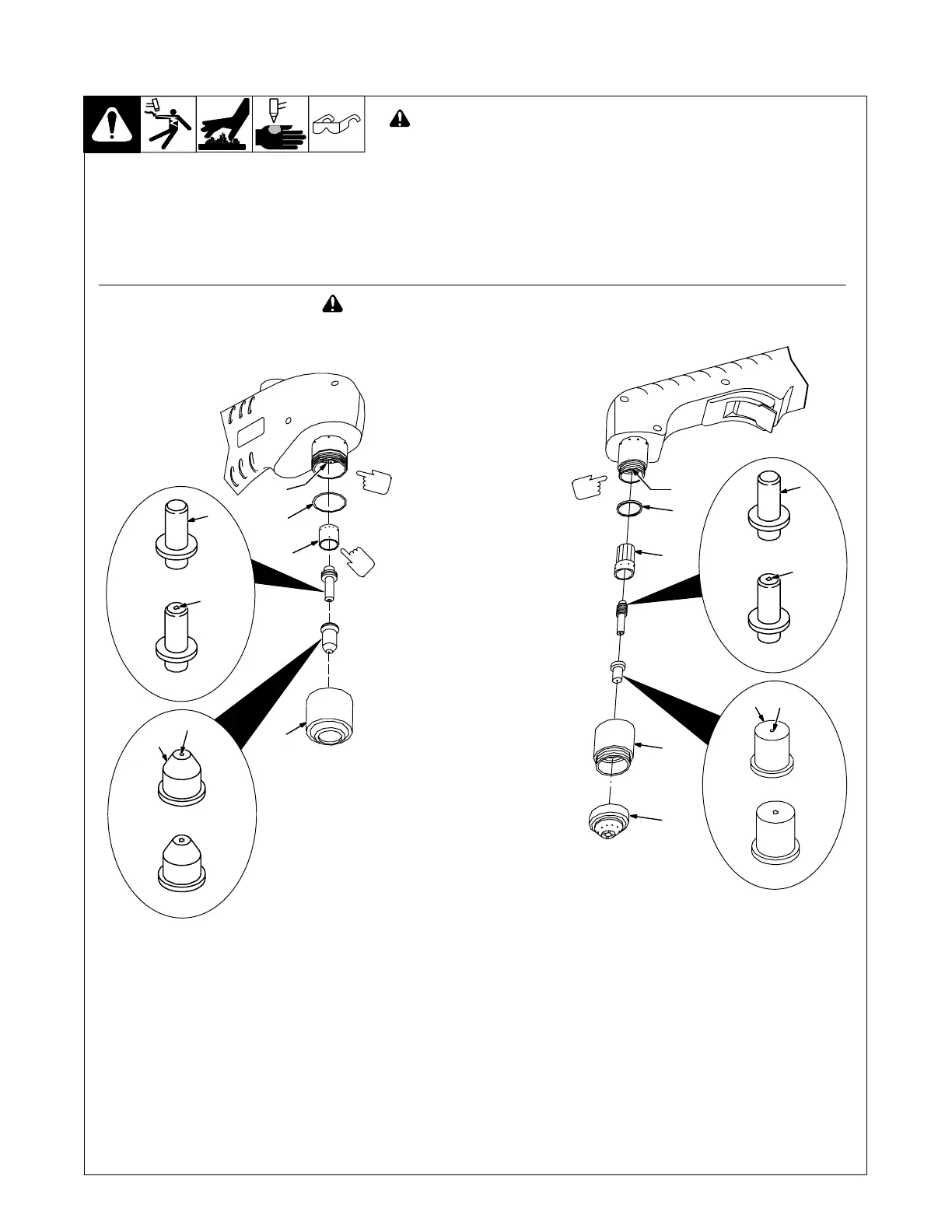

17. Checking/Replacing Retaining Cup, Tip, And Electrode For 25, 40, 50, And 55

Ampere Torches

NOTICE − Overtightening will strip threads. Do not overtighten electrode, tip,

and retaining cup during assembly. Do not cross-thread parts causing strip-

ping. Use care during torch assembly and parts replacement.

! Inspect shield cup, tip, and electrode for wear before cutting or whenever

cutting speed has been significantly reduced. Do not operate torch without

a tip or electrode in place. Be sure to use genuine replacement parts.

. A good practice is to replace both the tip and electrode at the same time.

Ref. 801 301 / 801 139 / Ref. 801 396-A / 801 405

Turn Off power source.

1 Drag Shield

2 Retaining Cup

Remove retaining cup. Check retaining cup

for cracks, and replace if necessary.

3Tip

4 Opening

Remove tip. Check tip, and replace if open-

ing is deformed or 50% oversize. If inside of

tip is not clean and bright, clean with steel

wool. Be sure to remove any pieces of steel

wool afterwards.

5 Electrode

Check electrode. If center has a pit more

than a 1/16 in (2 mm) deep, remove and re-

place electrode.

6 Swirl Ring

Remove swirl ring. Check ring, and replace

if side holes are plugged.

7 O-Ring

Check O-rings on torch. If needed, coat with

thin film of silicone lubricant (part no.

169 231). Replace if damaged.

8 Plunger Area

Check this area for any debris or foreign ma-

terial. Clean out if necessary.

Carefully reassemble parts in reverse order.

For the 25 ampere model, swirl ring must be

installed with word “front” facing away from

torch body.

6

Make sure this area is clean of

any debris.

New

Worn

New

Worn

2

5

4

3

7

8

The word “front” on swirl ring must

face away from torch body.

Make sure swirl ring is clean of any

debris and no holes are

obstructed.

! Turn Off power source before checking torch parts.

New

Worn

New

Worn

5

43

8

7

6

2

1

25 Ampere Model

50 Ampere and 55 Ampere Models

*1/32 in (1 mm) — 1/16 in (2 mm)

maximum pit depth depending on

acceptable cut quality.

*Pit

Depth

*Pit

Depth

Loading...

Loading...