Fastener Torque Requirements

PELLERIN MILNOR CORPORATION

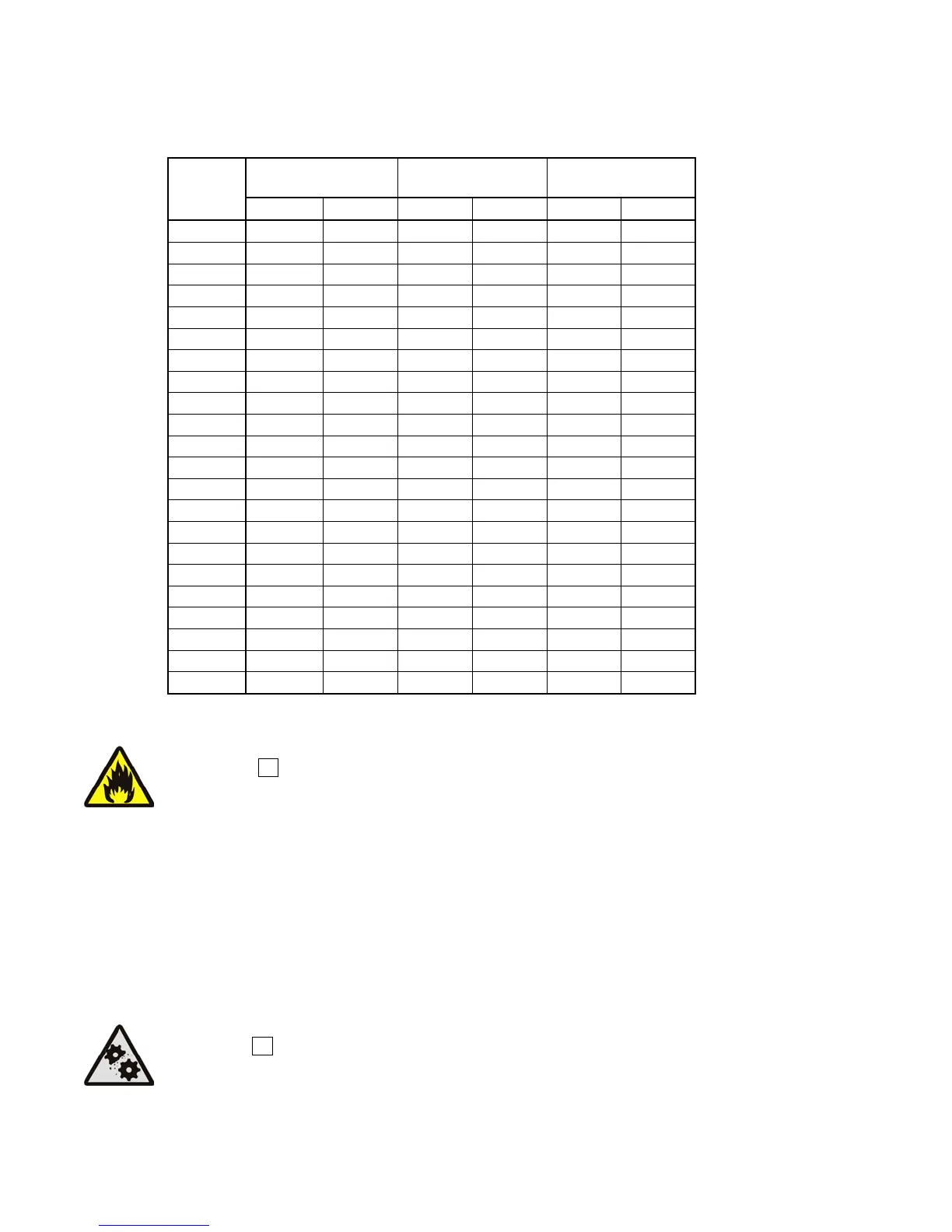

Table 12: Torque Values for Stainless Steel Fasteners Larger Than 5/16-inch

316 Stainless

18-8 Stainless

18-8 Stainless with

Loctite 767

Bolt Size Pound-feet N-m Pound-feet N-m Pound-feet N-m

3/8 x 16 21 28 20 27 12 16

3/8 x 24 23 31 22 29 13 18

7/16 x 14 33 44 31 42 19 25

7/16 x 20 35 47 33 45 20 27

1/2 x 13 45 61 43 58 26 35

1/2 x 20 47 64 45 61 27 37

9/16 x 12 59 81 57 77 34 46

9/16 x 18 66 89 63 85 38 51

5/8 x 11 97 131 93 125 56 75

5/8 x 18 108 150 104 141 62 84

3/4 x 10 132 179 128 173 77 104

3/4 x 16 130 176 124 168 75 101

7/8 x 9 203 275 194 263 116 158

7/8 x 14 202 273 193 262 116 157

1 x 8 300 406 287 389 172 233

1 x 14 271 367 259 351 156 211

1-1/8 x 7 432 586 413 560 248 336

1-1/8 x 12 408 553 390 529 234 317

1-1/4 x 7 546 740 523 709 314 425

1-1/4 x 12 504 683 480 651 288 390

1-1/2 x 6 930 1261 888 1204 533 722

1-1/2 x 12 732 992 703 953 422 572

2. Preparation

WARNING 1 : Fire Hazard—Some solvents and primer products are flammable.

• Use in a well ventilated area.

• Do not use flammable products near ignition sources.

1. Clean all threads with a wire brush, a tap, or a die.

2. Degrease the fasteners and the mating threads with a cleaning solvent. Wipe the parts dry.

Note 2: LocTite 7649 Primer N

™

will remove grease from parts, but it costs more than a standard

organic or petroleum solvent.

3. Prime the fasteners and the mating threads with LocTite 7649 Primer N

™

or equal. Allow the

primer to dry for at least one minute.

3. Application of Threadlocking Compound

CAUTION 2 : Malfunction Hazard—Improper application of threadlocking compounds may

result in fasteners becoming loose from impact, heat, or vibration. Loose fasteners can cause the

equipment to malfunction.

• Read and follow the threadlocking compound manufacturer's instructions and warnings.

Loading...

Loading...