5

WARNING 7RUHGXFHWKHULVNRILQMXU\

DOZD\VKROGVHFXUHO\

&OXWFK

6HWWLQJ

$SSOLFDWLRQV

1-5

6-10

11-15

16-20

21-24

3.2-4.4

Small screws in softwood.

Medium screws in softwood or small

screws in hardwood.

Large screws in softwoods. Medium

screws in hardwood or large screws in

hardwood with pilot hole.

127( Because the settings shown in the table are only

a guide, use a piece of scrap material to test the different

clutch settings before driving screws into the workpiece.

6HOHFWLQJ6SHHG

The speed selector is on top of the motor housing.

Allow the tool to come to a complete stop before

changing speeds. See “Applications” for recom-

mended speeds under various conditions.

1. For /RZ speed, push the speed selector to

display “1”.

2. For +LJK speed, push the speed selector to

display “2”.

8VLQJWKH&RQWURO6ZLWFK

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the ON/OFF switch is not pressed. Always allow

the motor to come to a complete stop before using

the control switch.

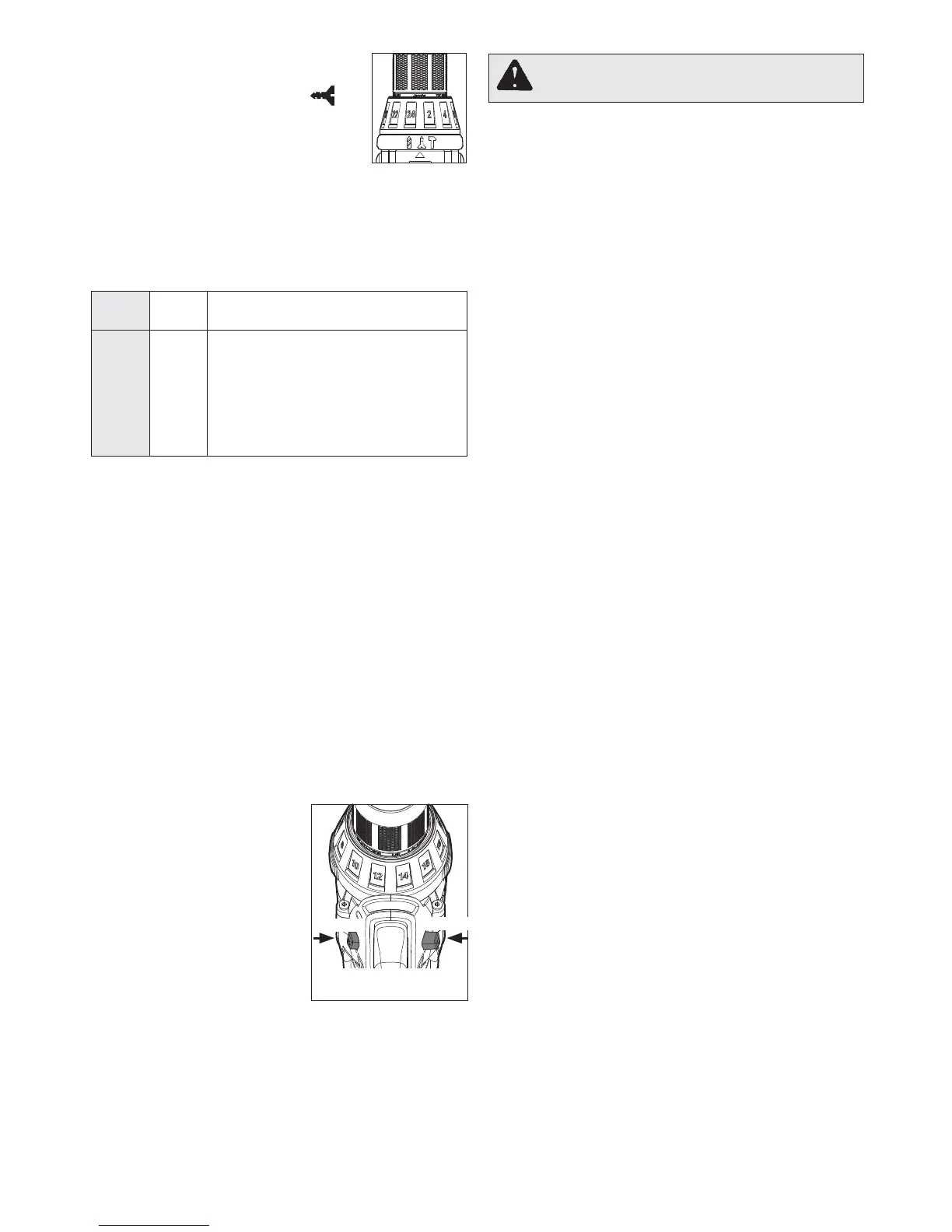

For IRUZDUG (clockwise)

rotation, push in the control

switch from the right side of

the tool. &KHFNWKHGLUHFWLRQ

RIURWDWLRQEHIRUHXVH

For UHYHUVH (counterclock-

wise) rotation, push in the

control switch from the left

side of the tool. &KHFNGLUHF-

WLRQRIURWDWLRQEHIRUHXVH

ToORFN the trigger, push the

control switch to the center

position. The trigger will not work while the control

switch is in the center locked position. Always

lock the trigger or remove the battery pack before

performing maintenance, changing accessories,

storing the tool and any time the tool is not in use.

3. 7RXVHWKHGULYLQJVFUHZVPRGH

rotate the application selector col-

lar until the drive symbol

0.5-2.8

Nm

ap-

pears in line with the arrow. Then

rotate the torque selector collar

until the desired clutch setting ap-

pears in line with the arrow.

The adjustable clutch, when properly adjusted,

will slip at a preset torque to prevent driving the

screw too deep into different materials and to

prevent damage to the screw or tool.

7KH WRUTXH VSHFL¿FDWLRQV VKRZQ KHUH DUH DSSUR[LPDWH

values obtained with a fully charged battery pack.

/RFN

3XVKWR

CENTER

5HYHUVH

)RUZDUG

6WDUWLQJ6WRSSLQJDQG&RQWUROOLQJ6SHHG

1. To VWDUWWKHWRROJUDVSWKHKDQGOHV¿UPO\DQG

pull the trigger.

NOTE: An LED is turned on when the trigger is

pulled.

2. To YDU\ the speed, increase or decrease the

pressure on the trigger . The further the trigger

is pulled, the greater the speed.

3. To VWRS the tool, release the trigger. Make sure

the bit comes to a complete stop before laying

the tool down.

'ULOOLQJ

3ODFHWKHELWRQWKHZRUNVXUIDFHDQGDSSO\¿UP

pressure before starting. Too much pressure will

VORZWKHELWDQGUHGXFHGULOOLQJHI¿FLHQF\7RROLWWOH

pressure will cause the bit to slide over the work

area and dull the point of the bit.

If the tool begins to stall, reduce pressure slightly

to allow the bit to regain speed. If the bit binds,

reverse the motor to free the bit from the workpiece.

3.6-7.7

9.7-10.8

8.2-9.5

Loading...

Loading...