Do you have a question about the Milwaukee M18 FMS254-0 and is the answer not in the manual?

Safe practices for the operating environment, including lighting and avoiding explosive atmospheres.

Precautions to prevent electric shock, such as matching plugs and avoiding wet conditions.

Measures to protect the operator's well-being, including staying alert and using protective equipment.

Methods to securely hold workpieces during cuts, using clamps or fences.

Techniques for cutting round stock safely, often using V-blocks.

Handling aluminum profiles and channels, using support blocks.

Precautions regarding sawdust and dust collection, including self-ignition risks.

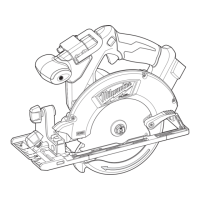

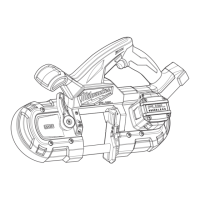

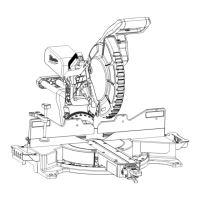

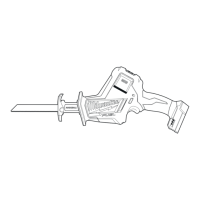

Labels and numbering of the saw's components for easy reference.

Key technical parameters of the mitre saw, including model and measurements.

Maximum cut sizes for various mitre and bevel angles.

Attaching handles for transport and support extensions.

Attaching the support leg for stability when the saw is on its side.

Procedures for moving and storing the saw safely.

How to lock the saw head in place for transport.

Securing the sliding mechanism for transport.

Securing the saw to a workbench or stand for stable operation.

Connecting a vacuum or dust bag to the dust port.

Attaching face boards to fences for workpiece support and splinter reduction.

Choosing the correct blade for the saw, considering RPM and material.

Identifying and respecting safe operating zones to prevent injury.

Choosing appropriate materials for cutting, avoiding warped or knotty wood.

Techniques for securing workpieces using clamps or fences.

Providing stability for extended materials using supports or tables.

Setting the horizontal cutting angle using detents or fine adjustment.

Setting the vertical cutting angle using detents or fine adjustment.

Using the laser guide for accurate cut placement.

Procedures for powering the saw on and off safely.

How to perform basic vertical cuts without using the sliding feature.

Aligning the back fence for proper support and safety.

Importance and function of safety guards, never to be disabled.

Locking the slide rails for non-sliding cuts.

Setting the maximum cutting depth for groove or rabbet cuts.

Steps for performing crosscuts with the sliding mechanism.

Materials that should not be cut with this saw, like stone or ferrous metals.

List of suitable materials for cutting, including wood, plastics, and non-ferrous metals.

Techniques for cutting cylindrical or angled materials using support blocks.

Settings for common 52°/38° and 45°/45° crown molding cuts.

Method for cutting molding flat on the table for stability and ease.

Method for cutting molding against the fence without complex bevel settings.

Regular checks and upkeep of the tool, battery pack, and charger.

Fine-tuning saw alignment for accuracy after shipping or handling.

Aligning the blade perpendicular to the fence for accurate mitre cuts.

Aligning the blade parallel to the table for accurate bevel cuts.

How to reach customer support, dealers, and service agents.