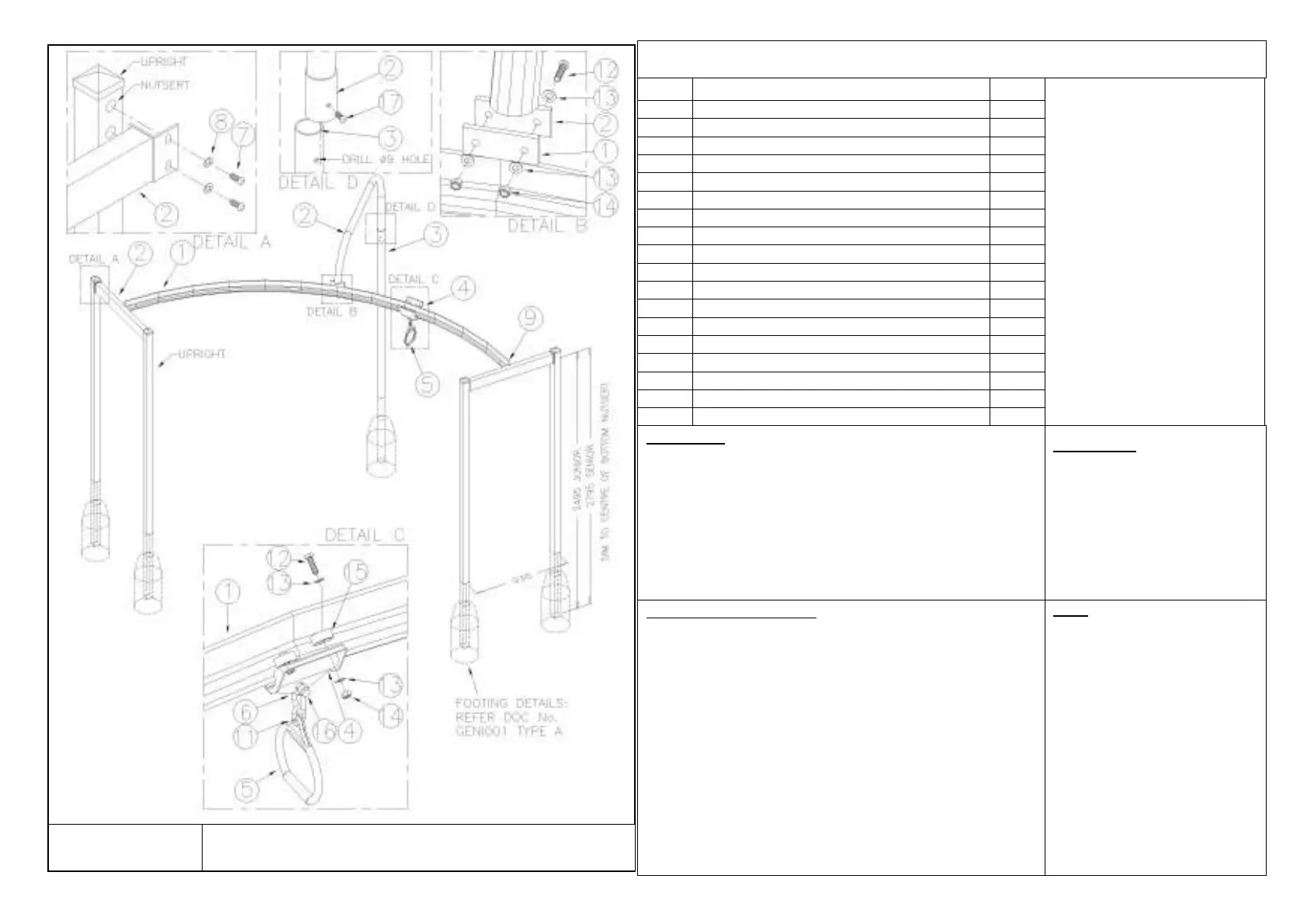

Item

Description Qty

Specifications

Curved Trackride Overhead

Curved Trackride Side Support Leg

External Trackride Carriage *

M12 D Shackle Galv * (Fitted)

Universal Trackride Buffer

Split Link 8mm Galv * (Fitted)

Nylon Wheel with Bearings *

M12x70mm H/T 8.8 Bolt Z/P

M10x20mm Trilobular Screw

Application:

Motion Ride

Maintenance

All fasteners should be regularly

checked and retightened, if necessary,

1 week after installation.

Ongoing maintenance intervals will vary

according to the amount of use the

equipment receives.

Recommend inspection intervals every 3

months.

* Wear Item - Refer Warranty

Installation Instructions:

1. Locate the item on the plan drawing & mark position.

2. Position the overhead & mark & dig footings. Lift the

Trackride into position & bolt using the M10x25mm Torx

Bolts (7) & M10 Flat Washers (8) under bolt heads.

3. Position & mark the side mount at 90

o

to the carriage rail &

excavate the required footing.

4. Bolt the side mount into position using the M10x40 Hex

Bolts with Washers each side & Nyloc Nuts.

5. Ensure the main carriageway is level concrete all posts &

fully tighten all bolts.

6. Remove the wheels from the carriageway & refit wheels.

Fully tighten all bolts. Do not use until concrete is cured.

In-ground Upright depth may vary

depending on Softfall

- Sand/Mulch/Grass–700mm (Pictured)

- Rubber – 500mm

+ 300mm Added to Upright depth if

component is Freestanding

+ Use ID tag as reference.

STRUCTURE: ____________________

MIRACLE: ______________________ DATE: ___________

Doc No. O-26

Loading...

Loading...