O-IO Maintenance techniques, tools and working facilities

It should be noted that many fasteners, especially Grades 0 through

2, have no distinguishing marks on them. When such is the case, the only

way to determine whether it is standard or metric is to measure the thread

pitch or compare it to a known fastener of the same size.

Standard fasteners are often referred to as SAE, as opposed to metric.

However, it should be noted that SAE technically refers to a non-metric

fine threadfastener only. Coarse thread non-metric fasteners are referred

to as USS sizes.

Since fasteners of the same size (both standard and metric) may have

different strength ratings, be sure to reinstall any bolts, studs or nuts re-

moved from your vehicle in their original locations. Also, when replacing

a fastenerwith a new one, make sure that the new one has a strength rat-

ing equal to or greater than the original.

Tightening sequences and procedures

Most threaded fasteners should be tightened to a specific torque value

(torque is the twisting force applied to a threaded component such as a

nut or bolt). Overtightening the fastener can weaken it and cause it to

break, while undertightening can cause it to eventually come loose. Bolts,

screws and studs, depending on the material they are made of and their

thread diameters, have specific torque values, many of which are noted

in the Specifications at the beginning of each Chapter. Be sure to follow

the torque recommendations cbsely. For fasteners not assigned a specif-

ic torque, a general torque value chart is presented here as a guide. These

torque values are for dry (unlubricated) fasteners threaded into steel or

cast iron (not aluminum). As was previously mentioned, the size and

grade of a fastener determine the amount of torque that can

Metric thread sizes

Ft-lbs

M-6 ................................. 6to9

M-8 ................................. 14to21

M-10 ................................ 28to40

M-12 ................................

5at07i

M-14 ...... .._._r-....*........._ .... 89to140

Pipe thread sizes

l/8 .................................. 5to8

t/4 .................................. 121018

3/8.............*- ................... 22to33

l/2 .................................. 25to35

U.S. thread sizes

i/4-20 .............................. 6to9

5/16-18.. ........................... 12tol8

5116-24 ............................. 14to20

318-16 .............................. 22to32

318-24 .............................. 27to38

7116-14 ............................. 40to55

7/16-20 ............................. 4Oto60

i/2-13 .............................. 55to80

Nm

9toi2

19to28

38 to 54

68 to 96

109to 154

7toio

17to24

3oto44

34 to 47

9toi2

17to24

19to27

30 to 43

37 to 51

55 to 74

55 to 81

75to 108

G-

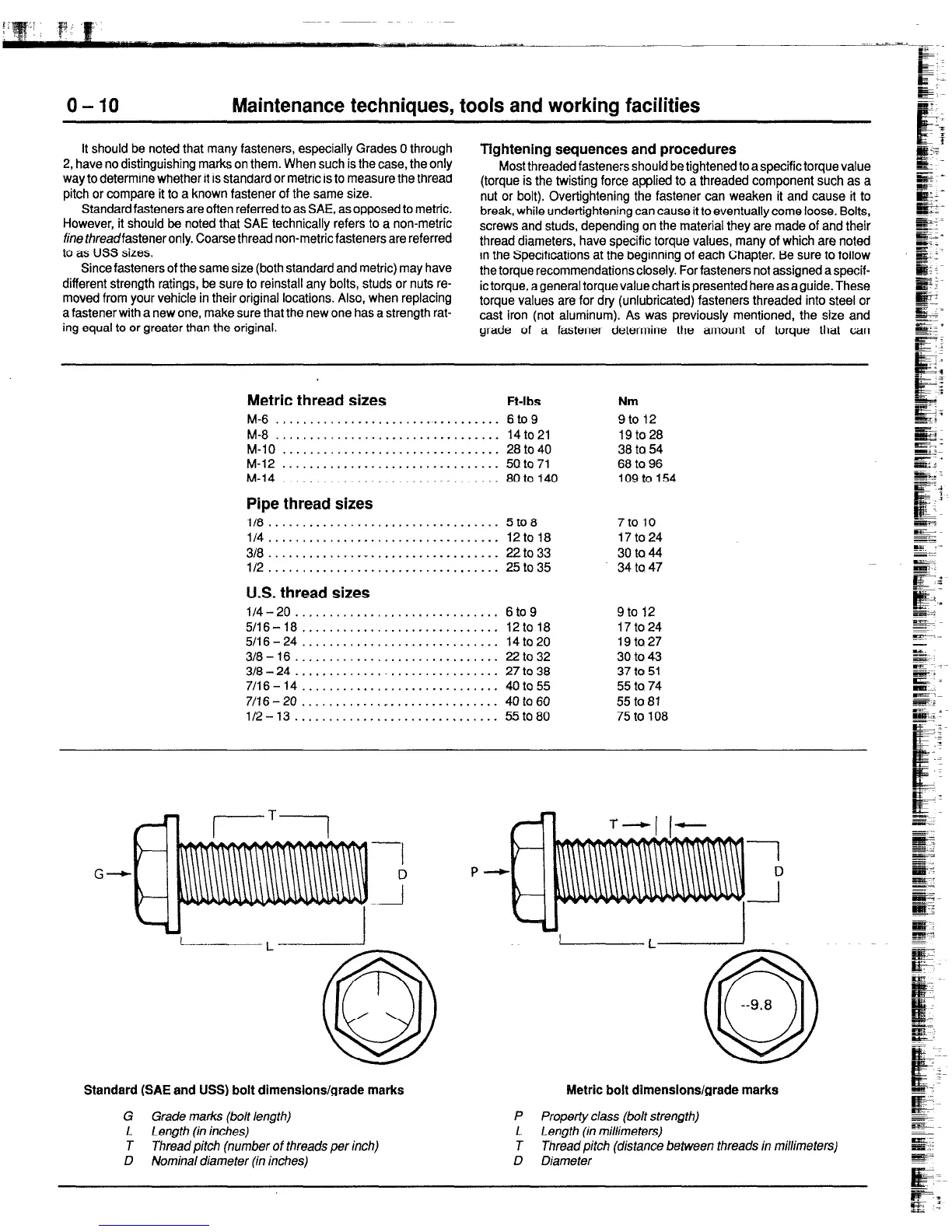

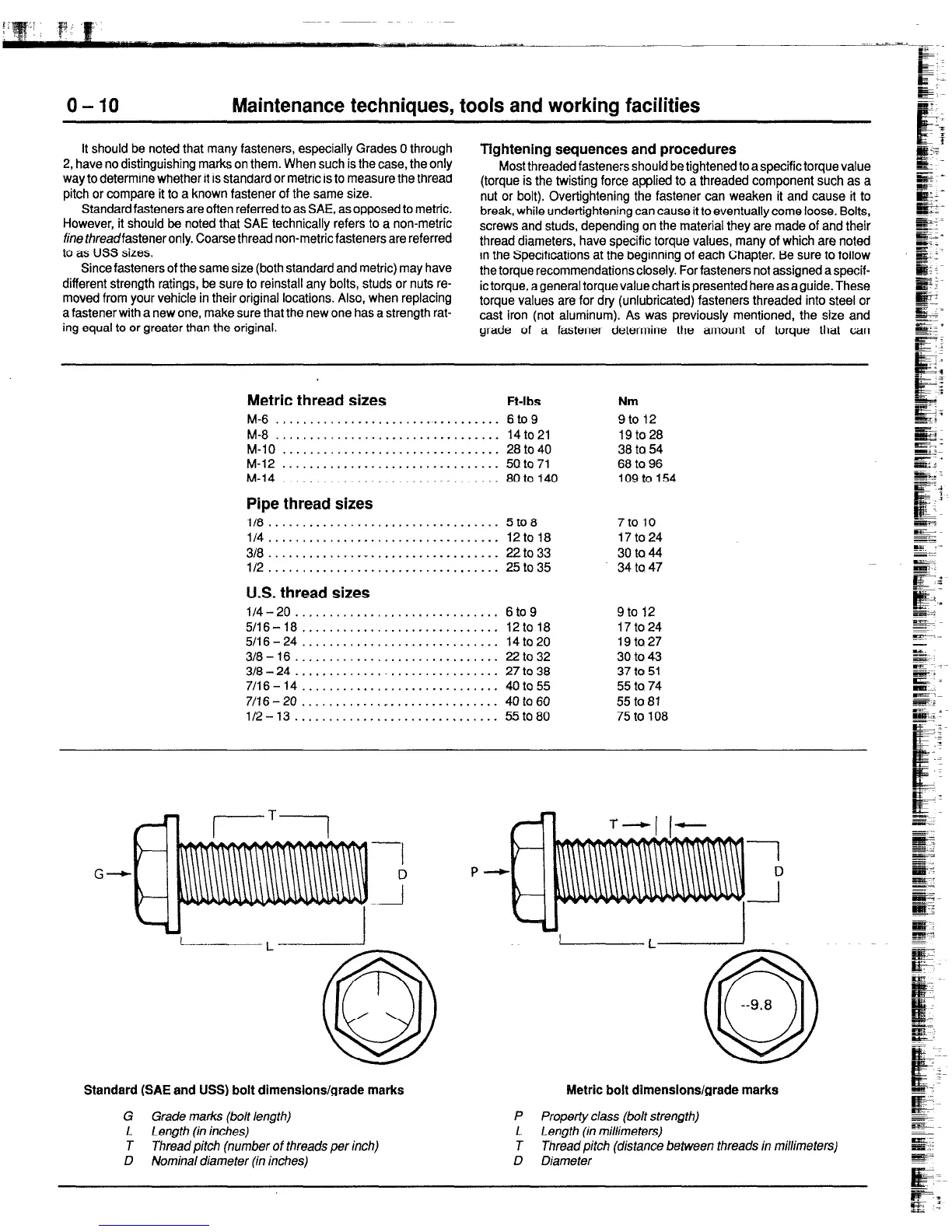

Standard (SAE and USS) bolt dimensions/grade marks Metric bolt dimensions/grade marks

G Grade marks (bolt length) P Property class [bolt strength)

L Length (in inches)

L Length (in millimeters)

T Thread pitch (number of threads per inch) T Threadpitch (distance between threads in millimeters)

D Nominal diameter (in inches) D Diameter

P-

Loading...

Loading...