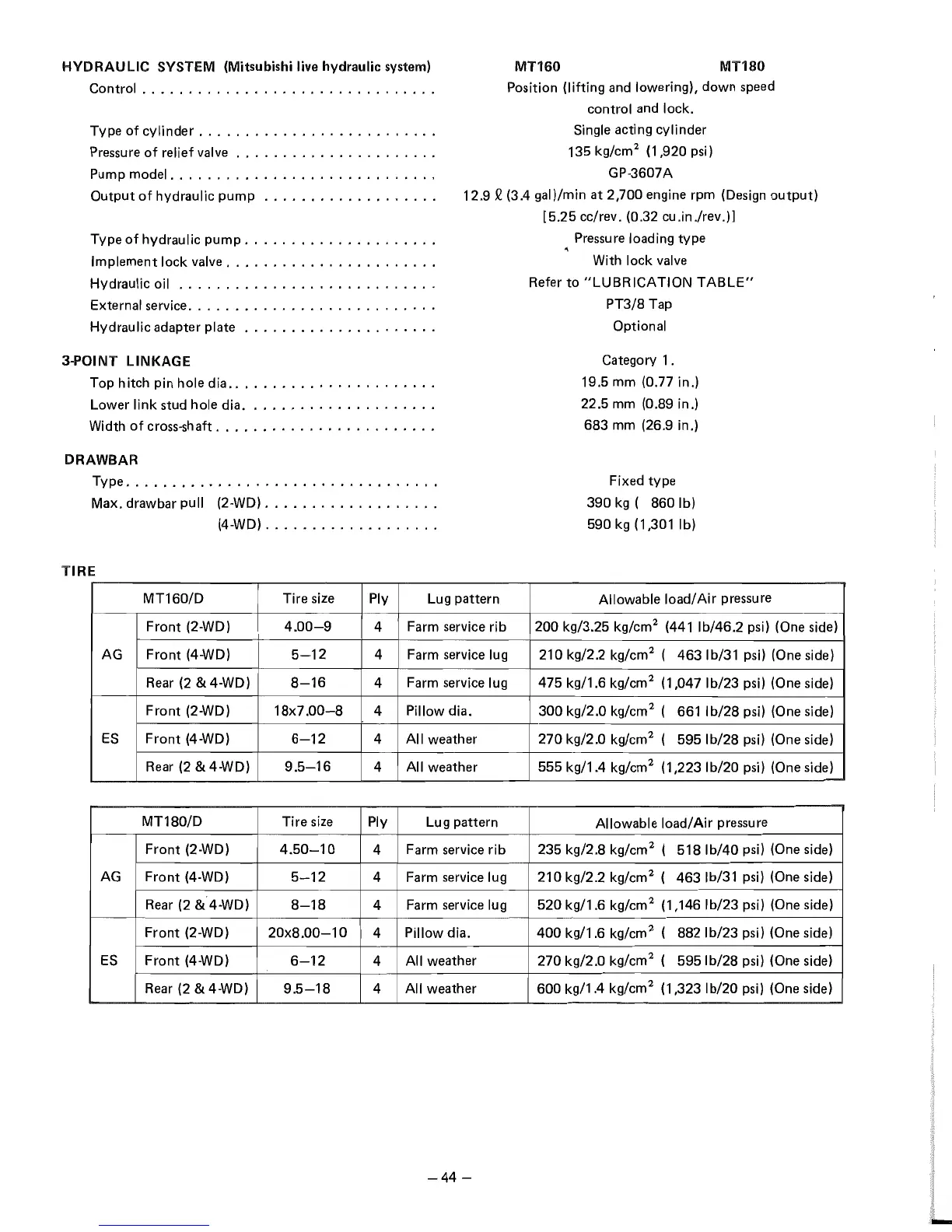

HYDRAULIC

SYSTEM (Mitsubishi live hydraulic system)

Control

...............................

.

Type

of

cylinder

.........................

.

Pressure

of

relief

valve

.....................

.

Pump model

............................

.

MT160

MT180

Position (lifting

and

lowering), down

speed

control

and

lock.

Single acting cylinder

135 kg/cm

2

(1,920 psi)

GP-3607A

Output

of

hydraulic pump

..................

.

12.9

Q (3.4 gal)/min at 2,700 engine rpm

(Design

output)

[5.25 cc/rev. (0.32 cu.in./rev.)]

Type

of

hydraulic pump

....................

.

Implement lock

valve

......................

.

Hydraulic oil

...........................

.

External

service

......

'

....................

.

Hydraulic adapter plate

3-POINT

LINKAGE

Top hitch pin hole dia

......................

.

Lower

link

stud hole dia

....................

.

Width

of

cross-shaft

.......................

.

DRAWBAR

Type

.................................

.

Max. drawbar pull (2-WD)

..................

.

(4-WD)

..................

.

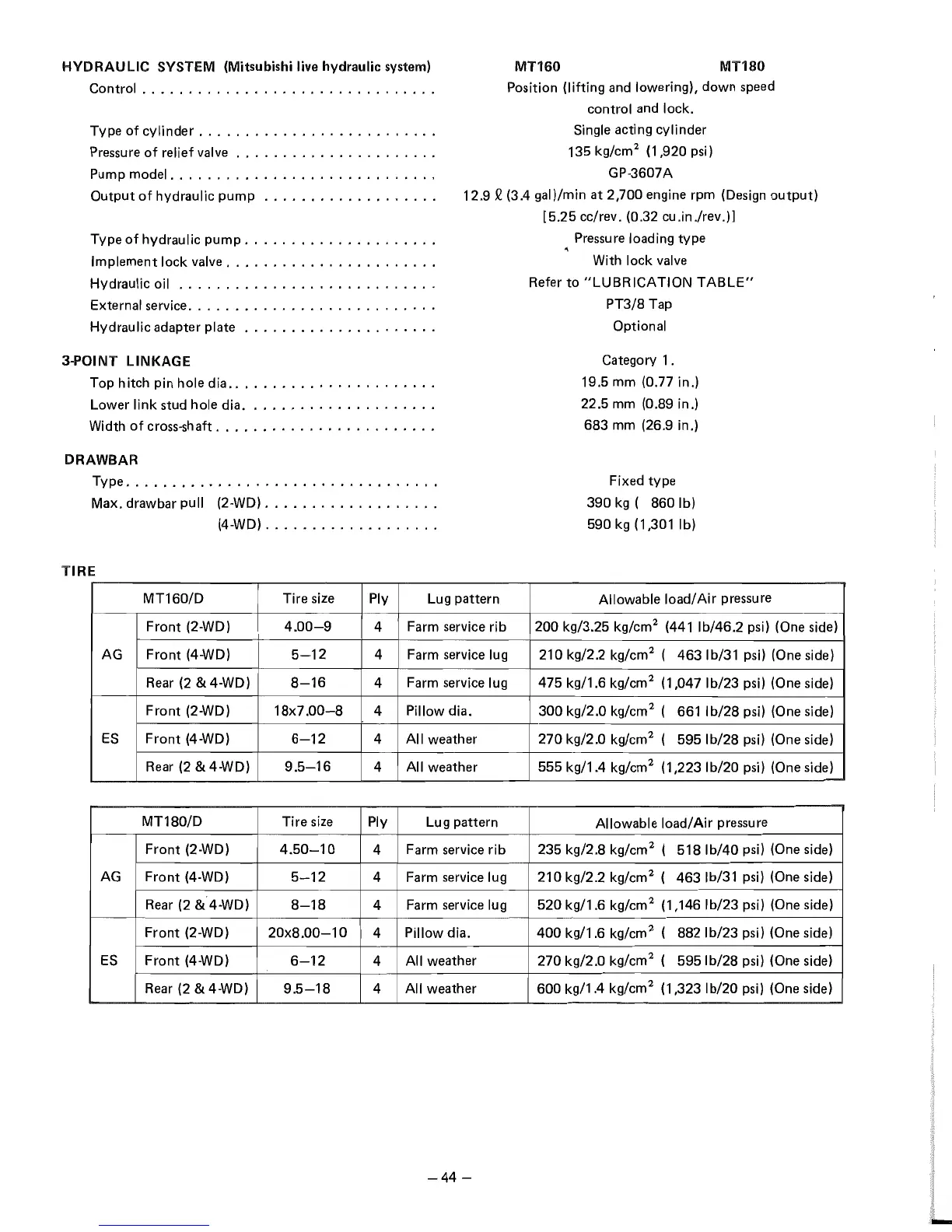

TIRE

MT160/D

Tire

size

Ply Lug pattern

Front (2-WD)

4.00-9

4

Farm service rib

AG

Front (4-WD)

5-12

4

Farm service lug

Rear

(2

& 4-WD)

8-16

4

Farm service lug

Front (2-WD)

18x7.00-8

4

Pillow dia.

ES

Front (4-WD)

6-12

4

All

weather

Rear

(2

& 4-WD)

9.5-16

4 All weather

MT180/D Tire

size

Ply

Lug pattern

Front

(2-WD)

4.50-10

4 Farm service

rib

AG Front (4-WD)

5-12

4 Farm service lug

Rear

(2

&4-WD)

8-18

4 Farm service lug

Front (2-WD)

20x8.00-10

4

Pillow dia.

ES

Front (4-WD)

6-12

4

All weather

Rear

(2

& 4-WD)

9.5-18

4

All weather

-44

-

Pressure

loading type

With lock

valve

Refer to

"LUBRICATION

TABLE"

PT3/8

Tap

Optional

Category 1.

19.5 mm (0.77 in.)

22.5

mm

(0.89 in.)

683

mm

(26.9 in.)

Fixed type

390

kg

( 8601b)

590

kg

(1,301 Ib)

Allowable

load/Air

pressure

200 kg/3.25 kg/cm

2

(441

Ib/46.2 psi) (One side)

210 kg/2.2 kg/cm

2

(

4631b/31 psi)

(One

side)

475 kg/1.6 kg/cm

2

(1,047 Ib/23 psi) (One side)

300 kg/2.0 kg/cm

2

(

661

Ib/28 psi)

(One

side)

270 kg/2.0 kg/cm

2

(

595 Ib/28

psi)

(One side)

555 kg/1.4 kg/cm

2

(1,223 Ib/20

psi)

(One side)

Allowable

load/Air

pressure

235 kg/2.8 kg/cm

2

(

5181b/40 psi)

(One

side)

210 kg/2.2 kg/cm

2

(

463 Ib/31

psi)

(One

side)

520 kg/1.6 kg/cm

2

(1,146 Ib/23 psi)

(One

side)

400 kg/1.6 kg/cm

2

(

8821b/23 psi) (One side)

270 kg/2.0 kg/cm

2

(

595 Ib/28 psi) (One

side)

600 kg/1.4 kg/cm

2

(1,323 Ib/20

psi)

(One

side)

Loading...

Loading...