59

comes:

rated voltage

ra

e

capac

y

I

e

= x duty factor

=

200

85 + 10

3

x 0.5 = 300A

Hence, the MCCB rated current becomes:

I

MCCB

= I

e

x 1.15 = 300 x 1.15 = 345A

(i.e., the next higher standard value).

The relationship between the duty factor, which

does not exceed the working limitations, and the maxi-

mum permissible input I

β

at the above duty factor is:

β

I

e

I =

β

300

=

β

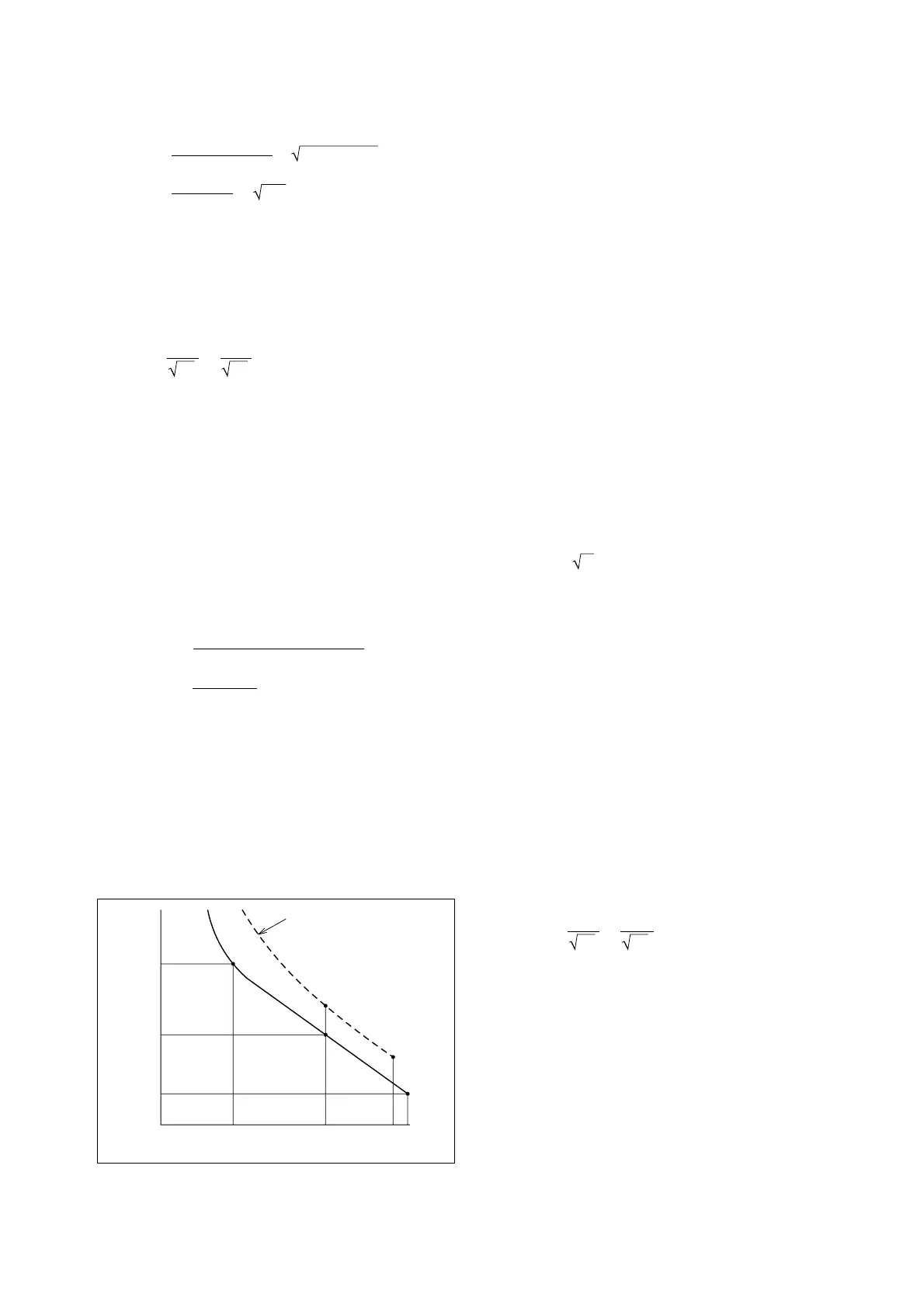

If the total period is taken as 60 seconds and the

duty factor is converted into the actual period during

which current flows, the above relationship can be

expressed graphically as in Fig. 7.6. Thus, although

the thermal equivalent current is 300A, the maximum

permissible input current for a duty factor of 50% (30

seconds current flow) is 425A. For a duty factor of

6.25% (3.75 sec current flow) it is 1200A. Even if the

secondary circuit of the welder were short circuited,

however, the resultant primary current would only in-

crease by about 30% over the standard maximum

welding current. If this is 400kVA, the maximum pri-

mary current I

βmax

is:

primary voltage

standard maximum input

I

max

= x 1.3

200

400 x 10

3

x 1.3 = 2600A=

β

Hence the maximum input current I

β

should be re-

stricted to 2600A.

The 75% hot-start characteristic of the 350A Type

NF400-SP breaker is shown by the broken line in Fig.

7.6, and the temperature-rise characteristics up to the

upper limit of the welder, by the solid line. To ensure

protection of the welder from burnout, the delay-trip

characteristic is selected at higher than the solid line;

however, to establish MCCB protection criteria, it is

necessary to look at each welder individually.

Operating time (s)

30

3.75

0.6

425

Primary input current (A)

Type NF400-SP·350A 75%

hot start

10"

2"

300026001200

Fig. 7.6 Welder Temperature Rise and MCCB Trip Curve

7.4.2 MCCB Instantaneous Trip and Trans-

former Excitation Surge

When a welding-transformer primary circuit is closed,

depending upon the phase angle at the instant of clo-

sure, a transient surge current will flow, due to the

super-imposed DC component and the saturation of

the transformer core.

In order to prevent spurious tripping of protective

devices resulting from such surges, and also to main-

tain constant welding conditions, almost all welders

currently available are provided with a synchronized

switch-on function, with or without wave-peak con-

trol.

With synchronized switch-on, the measured ratio

between the RMS value of the primary current under

normal conditions and the maximum peak transient

current ranges from √

2 ~ 2.

For nonsynchronized soft-starting-type welders the

measured ratio is a maximum of 4.

Maximum instantaneous transient surge excitation

currents for various starting methods are as follows:

Synchronized switch-on welders with wave peak con-

trol:

I

max

= 2 x I

max

Synchronized switch-on welders without wave peak

control:

I

max

= 2 x I

βmax

Nonsynchronized switch-on welders with soft start:

I

max

= 4 x I

βmax

Nonsynchronized switch-on welders without soft start:

I

max

= 20 x I

βmax

If synchronized switch-on is employed, the tran-

sient surge excitation currents are relatively consis-

tent, so that the relationship I

max

= 2 I

βmax

is suffi-

cient.

For a synchronized switch-on type welder of maxi-

mum primary input (I

βmax

) = 2600A

I

max

= 2 x I

βmax

= 2 x 2600 = 5200A

Since MCCB instantaneous trip currents are speci-

fied in terms of RMS value, I

inst

is as follows:

2

I

max

I

inst

= = 3680A

2

5200

=

The MCCB should be selected so that I

inst

is smaller

than the lower tolerance limit, of the instantaneous

trip current.

7.4.3 Arc Welders

An arc welder is an intermittent load specified. The

MCCB rating can by selected by converting the load

current into thermal-equivalent continuous current. If

this is taken as the rated current, however, the cur-

rent duration per cycle will become relatively long, with

the attendant danger of thermal tripping of the MCCB.

In the total period of 10 minutes, if the duty factor is

50%, a 141% overload exists for 5 minutes; if the duty

factor is 40%, a 158% overload exists for 4 minutes;

and if the duty factor is 20%, a 224% overload exists

Loading...

Loading...