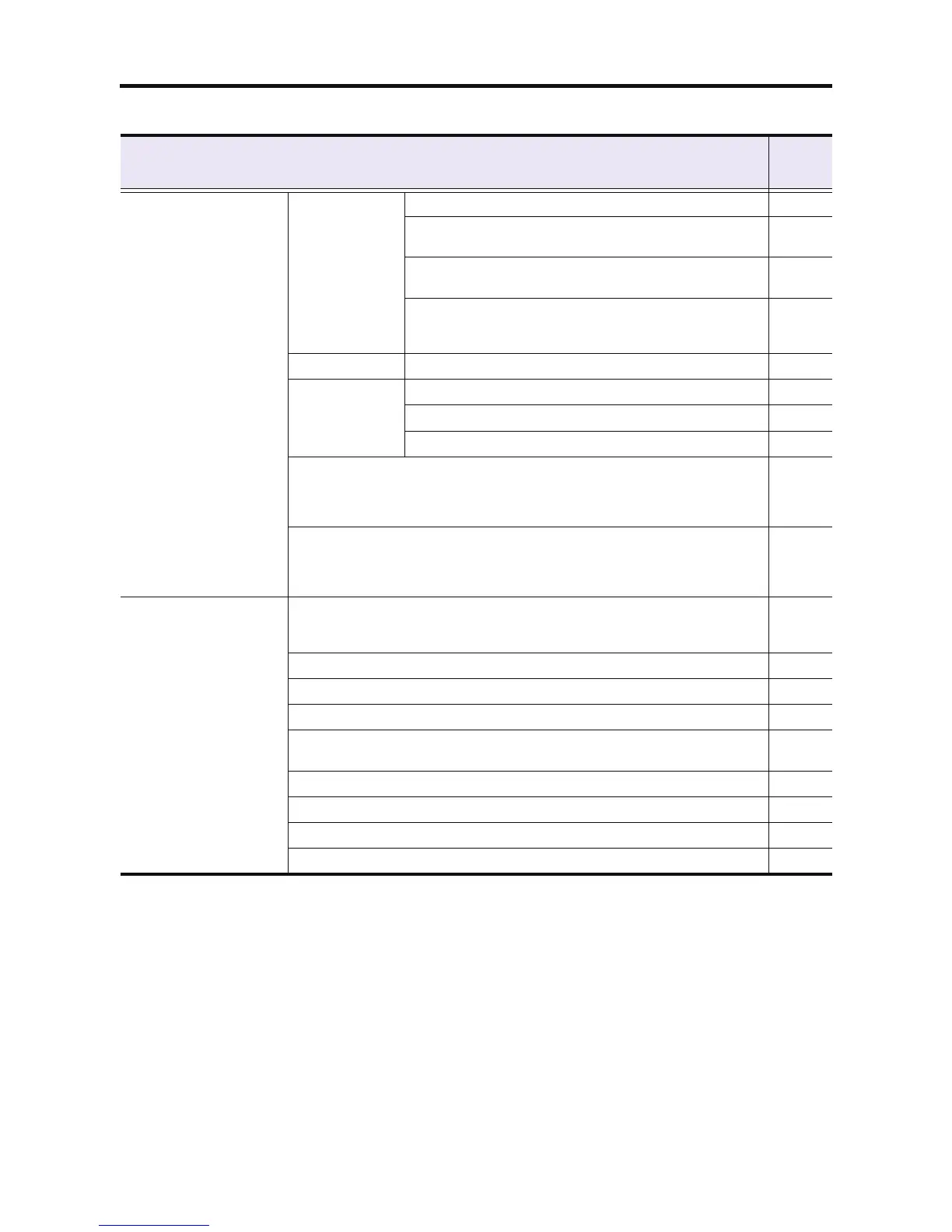

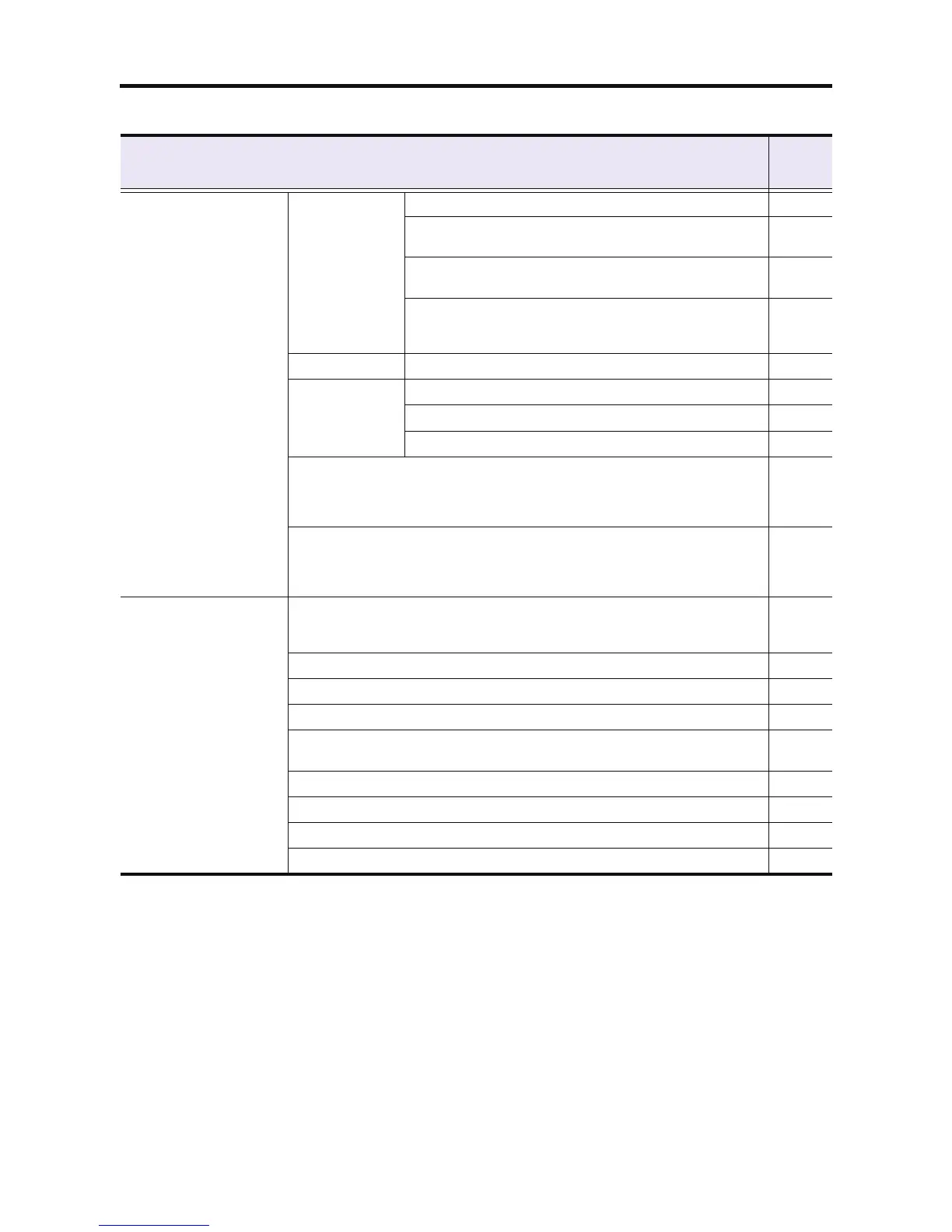

7-5

Chapter 7 MAINTENANCE SCHEDULE

Every 1 year

Cooling system

Water pump - Inspect *2

Solenoid valve and Pressure reducing valve of the cool-

ing system - Inspect, Disassemble and Clean*1

*2

Strainer (including with/ball tap) of cooling water -

Inspect, Disassemble and Clean*1

*2

Coolant properties (when only soft water is used) -

Inspect (Change coolant according to the analysis

results)

*2

Air intake system Air cleaner element - Clean, Check and Replace*1 8-17

Electrical system

Starter - Inspect 8-19

Alternator - Inspect 8-19

Specific gravity of battery electrolyte - Check*1 8-18

Protection devices operation - Inspect*1

High coolant temperature, low oil pressure, overspeeding, starting failure,

water supply failure, undervoltage, overvoltage, overcurrent, low coolant

level in tank, low fuel level in tank, etc.

*2

Auxiliary devices operation - Checkt*1

Engine control, fuel transfer pump, governor motor, room ventilating fan,

solenoid, storage pump, water tank ball tap, water heater, oil heater, oil prim-

ing pump, etc.

*2

Every 2 years

Engine oil, Oil filter and Bypass oil filter - Replace

It is recommended to check the engine oil characteristics at the same time.

The oil filters must be replaced when the filter alarm lights.

8-9

Fuel filter - Replace 8-7

Water separator - Inspect and Replace*1 *2

Gauze filter - Clean 8-6

Fuel control link ball joint - Inspect

(Replace parts as necessary)

8-6

Coolant - Change 8-13

Thermostat - Inspect *2

Turbocharger - Inspect 8-16

Draining water from the exhaust muffler*1 8-16

Table 7-2 Periodic maintenance chart for emergency engine

Interval and Service item

Refer-

ence

page

Loading...

Loading...