OPERATING INSTRUCTIONS | 13

7. Always maintain proper vertical alignment between the

suspension and pile when driving or pulling the pile.

8. Occasionally the inability of the V-2Esc hammer to continue to move a pile will

be the result of the pile striking an impenetrable soil material or an obstruction.

The observable action of the V-2Esc hammer and clamped pile will be to note a

considerable fall-off of drive pressure and the exciter will “dance” in place often

causing erratic interaction of the V-2Esc exciter and its suspension assembly. If the

V-2Esc is mounted to an excavator or backhoe do not apply more crowd force than

the maximum recommended.

Whenever the V-2Esc hammer is observed “dancing or

chattering” in place, it should be hoisted until the action stops. Failure to

move a pile with the hammer “dancing or chattering” should be cause to

promptly abandon the effort before serious damage is done to the hammer.

To continue operations the obstruction must be removed or penetrated by

switching to another driving system such as a larger vibro or a MKT diesel or

air pile hammer.

For each lift, the operator must review the excavator lifting

capacity to determine that the weight of the V-2Esc/Rototilt assembly plus the

load being lifted is within the rated capacity of the excavator.

Keep hands clear of all three clamps at all times.

Leave the pile line attached to the pile at all times that the pile is

not stuck securely in the ground.

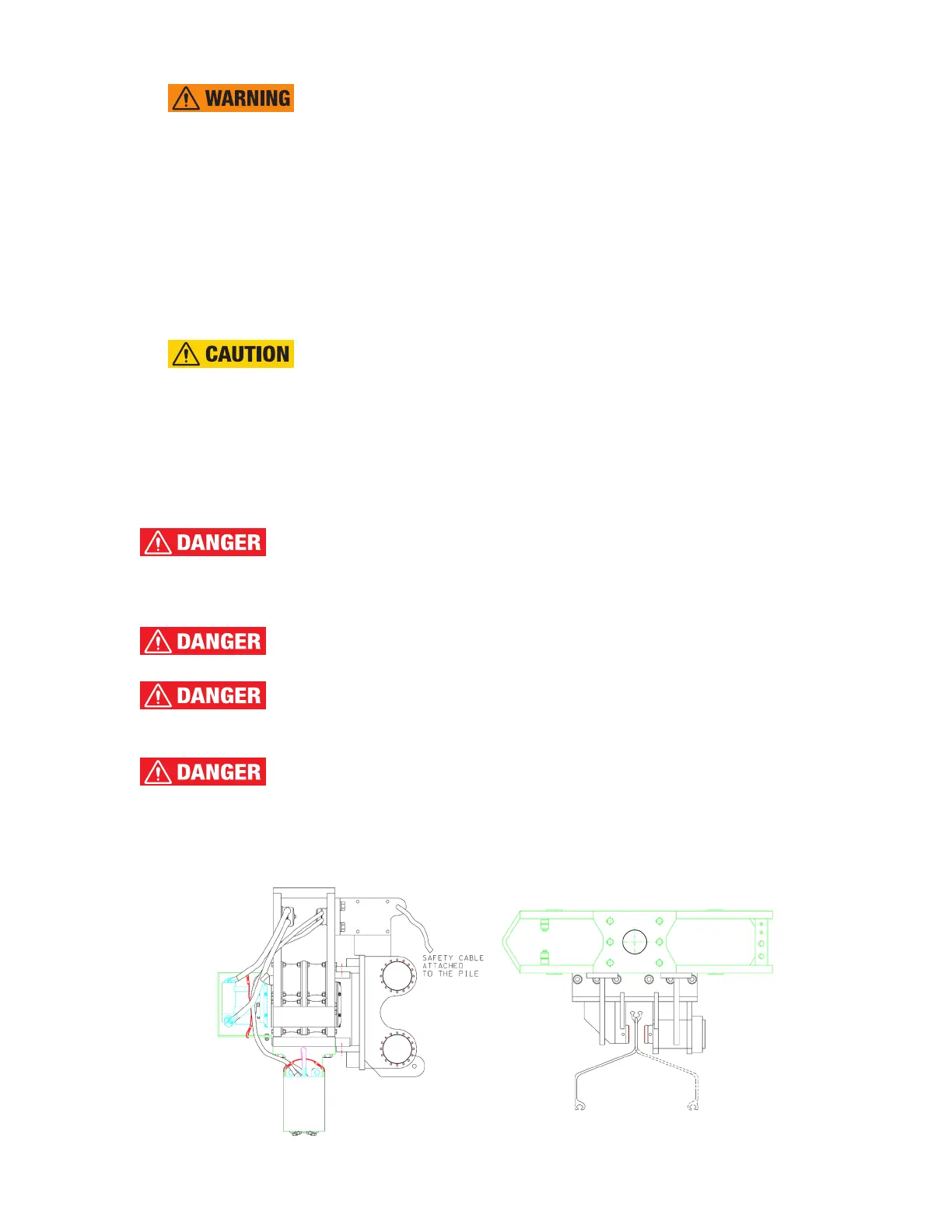

The V-2Esc side clamp attachment is designed to handle a single

pile with a MAXIMUM weight of 2 TONS. Appropriate pile lifting rigging should be

supplied by the end user to handle the pile in a safe manner. Attach cable(s) to

lifting eye(s) on the hammer to allow safe handling of the pile and placing it in the

jaws as shown in gure 2.

Figure 2

Loading...

Loading...