MX Eco-touch Rotary Rack Gas Oven (FG166)

Rev. B21 21-05-21 MONO EQUIPMENT

20

GAS CONNECTION

Ovens will be supplied with a bespoke burner that will be set-up prior to dispatch.

The burner is suitable for use with natural gas only.

The burner output is 50 kW.

Heat output Gas pressure at connection point Gas flow with burner in operation

50 kW 20.0 mbar 5.16 m³/h

Warning

Burner installation and start-up should be carried out by an authorized technician.

Local regulations for gas installations must be followed.

Always check the nameplate for the gas type.

Do not use the burner with other gas types.

Repairs and maintenance to be carried out by an authorised service engineer.

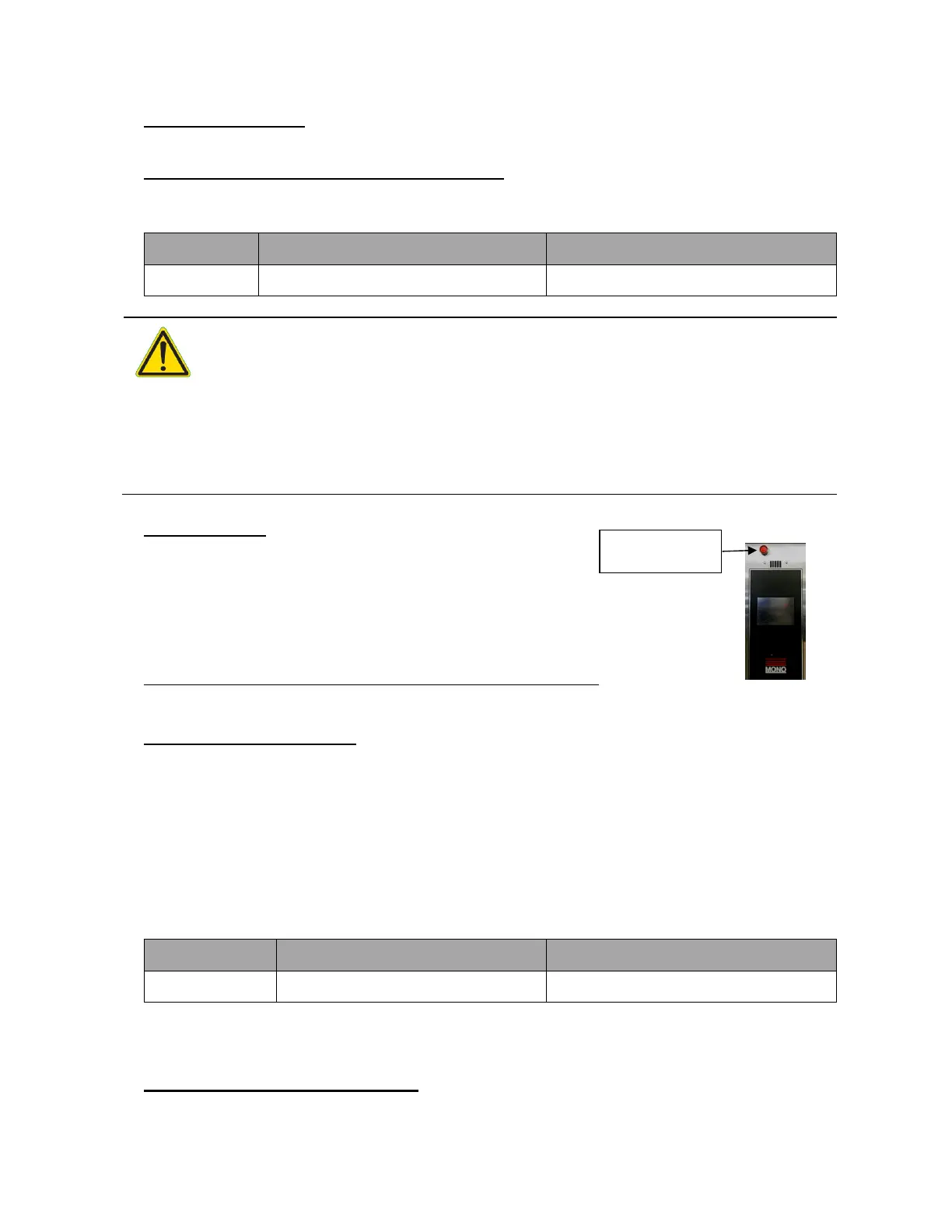

Burner reset

The burner reset button is located above the control panel.

After 3 failed attempts of igniting, the button will illuminate

Signalling that the burner has locked out.

To reset , press the button until the light goes out.

The burner will then attempt to ignite 3 more times.

If the burner continuously fails, contact a qualified gas engineer.

FLUE GAS CONNECTION

Connection on oven: Outside diameter Ø130 mm.

Draft Conditions: There must be a negative pressure of 1 to 5 mm WG in the

combustion chamber. If the pressure is higher than 0mm WG in

service, a flue gas fan must be installed.

Temperature: The gas exhaust flue must be capable of withstanding a temperature

of at least 400 °C.

Heat output Flue gas temperature Flue gas quantity

50 kW 400 °C 150 m³/h

Note: None of the flue gas ducts should slope downwards or be horizontal (if no flue gas fan is

installed). The slope must be upwards towards the chimney.Avoid too many sharp elbows

Initial burning-off procedure

All ovens undergo the burn-off procedure in the factory before being dispatched.

BURNER RESET

BUTTON

Loading...

Loading...